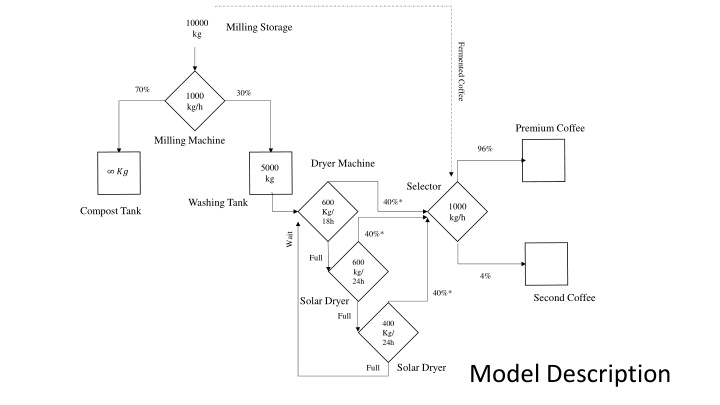

Coffee Processing Workflow and Quality Control

This detailed content outlines the workflow of processing coffee, from receiving 4000 kg of coffee beans daily to milling, drying, selection, and packing processes. The quality control measures such as grain quality checks and selection based on recipe rules are highlighted, along with the utilization of various machines and drying methods like solar dryers. The workflow emphasizes the need for workers at different stages to ensure efficient coffee processing and maintain product quality.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

10000 kg Milling Storage Fermented Coffee 70% 30% 1000 kg/h Premium Coffee Milling Machine 96% Dryer Machine 5000 kg ?? Selector Washing Tank 40%* 600 Kg/ 18h 1000 kg/h Compost Tank 40%* Wait Full 600 kg/ 24h 4% 40%* Second Coffee Solar Dryer Full 400 Kg/ 24h Solar Dryer Model Description Full

4 macro-processes Milling process Selection process Packing Process Drying process

1 Every day the model is fed with an average of 4000 kg of coffee bean. The Truck (Discrete part is divided in 4000 pieces of volume) 2 The coffee is deposited in the tank that supplies the mill, with a capacity of 10000 kg, this process requires a worker to help unload the shipment Grain Quality: If storage milling reach more than 90% the quality is affected, warning level 0=Normal (Recipe in the selector 96% Premium 4% second, 1=Coffee fermented (Recipe in the selector 60% Premium 40% second) Due to gravity, coffee falls directly to the mill, which has a nominal capacity of 1000 kg / hour Milling Process The mill is responsible for separating the coffee bean from its skin,(Recipe action used) resulting in two products, 70% being the skin removed and 30% the useable grain.

From the washing tank, the coffee is sent by means of piping and by gravity to the different dryers Drying Process Workers required for all flows Solar dryers and Drayer Machine require a cleaning that takes the worker approximately 2 hours Priority number one is given to the drying machine (works 24 hours a day) Capacity 600Kg/18h. coffee loses 60% of its weight given its moisture Recipe Priority number two and three have solar dryer 1 (600 kg /24h) and solar dryer 2 (400 kg/24) coffee loses 60% of its weight given its moisture. Depends on the daily sunshine hours, Climate model added as a Breakdown

Selection Process Workers required for all flows Cleaned for each process The three drying stations are connected to the Selector by pipe Premium and second quality are selected by Recipe Rule, the quality is affected due to delays It has a nominal selection capacity of 1000kg / hour

Packing Process Each machine requires a worker to operate, where it is responsible for putting the bag and make the process of filling and closing the bag Two input pipes (premium and second quality) Volume of 50 is packed in a bag (Continuous parts are compacted 1 discrete part) Workers required for all flows