Challenges and Innovations in the XPS Industry

The XPS industry faces challenges in physical properties and cost constraints, with various alternatives and current approaches in different regions. Technologies like CO2-based foams are emerging, but face issues like insulation reduction and density penalties. Compromises on physical properties are seen in different foam types. The industry is seeking solutions for replacement, focusing on ODP, GWP, and safety concerns.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

XPS INDUSTRY XPS INDUSTRY Mena Region Mena Region Alternatives currently offered to the XPS industry, compromises on physical properties, cost constraints on process development. A.K Chotani

Information provided in this Presentation is based upon our best knowledge gained through various publications and own experience: Producing XPS Foams Since: 1981 in Kuwait 1996 in South Africa Operating atmospheric and HydroVac process lines Produced and sold 400,000 m3/yearly Information provided is without any prejudice to any manufacturer who may support different views.

Current and Future BA Approaches Region Specific Europe:CO2/ethanol with HC or HFC or DME as CO-BA- doesn t meet -R5. Japan: HC (n-butane or iso-pentane) < R5. North America: HFC with CO2as CO-BA plus additives meet - R5. MENA :HCFC and HFC meets - R5 HC doesn t meet - R5.

Compelling Issues for Replacement BA KEY ISSUES ODP REMARKS Successfully Replaced CFC s HCFCs(Blends) 142B+22 HFCs(Blends) 134a 152a HCS ODP Under phase out GWP Under phase out Zero ODP Acceptable Low GWP Flammability Safety Concerns Co2+Co BA Ethanol,DME Processablity Flammability Acceptable Low GWP HFO s+Co BA 1234ze,DME Cost Concerns Acceptable Low GWP

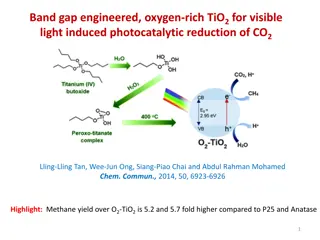

Summary of CO Summary of CO2 2Technology Current Situation: CO2based foam products has been in the market for around 10 yrs. Products include 1200mm or 600mm in width, and up to 120mm in thickness.(A few Manufacturer have succeeded to make higher thicknesses) Technology CO2 is always used with CO-BA, e.g. with ethanol, DME. Current Problem: 15 to 20% reduction in insulation R-value: 4 to 4.2 vs. 5 10 to 20% density penalty: 2.2 to 2.4 vs. 2 pcf. Difficult to make thick (>50mm) products need using such as high MI resin, BA with HCs or Moderate HFC.

Compromises on Physical Properties Properties HCFC/HFC HC/CO2+COBA Thermal Conductivity (EN 12 667/13164) Annex c Water Absorption (After diffusion) EN 12088 Dimensional Stability EN 1604 .029-.032 w/mk 0.036-.041 w/mk 0.3% by volume 3 5 % by Volume < 2 % <5% Compression Strength EN 826 175 -700 KPA 150 700 KPA These values doesn t refer to any particular manufacturer.

High Performance Products Two Manufacturers have introduced their XPS products giving 20% better thermal Performance using CO2 technology than their conventional products produced with same technology. They achieved this by adding special additives(Infrared blockers),whose finely-dispersed particles reflect radiant heat thus reducing heat loss. These are patent technologies and manufacturers are not known for offering Licencee agreements or franchise. The probability to acquire this Knowledge/Technology is nonexistent.

Cost Constraints on Process Development A few manufacturer are backed by technology Partners. Big Groups have their own R&D which supports innovation &advancement. Small Manufacturer have limited resources and their access to information and experience is very limited. Most of the small manufacturer in MENA Region have process lines not backed by Technology Assistance and not supplied by renowned Manufacturers. Small Manufacturers will go for use of HCs which are Low Capital intensive. Established companies have chosen the route of CO2 technology. Currently use of HFOs is not pursued because of its high cost and availability concerns.

Dilema faced by MENA REGION There is no unified approach on the selection and use of LOW GWP BA. The reasons are attributed to dissimilar application requirements, different building codes and standards followed by different regions. MENA region follows ASTM standards for the specification of XPS thermal insulation boards since 1983 when its first Energy Conservation Code was established in the Gulf region. North American market follows ASTM C-578-14 which specifies requirement of R-5.Use of HFC is currently prevalent with CO2plus additives.

Use of the CO2 technology employed would produce a product that doesn t meet R-5. Current Specification in Gulf region asks for Zero ODP and <5 GWP Product, physical properties expected as per ASTM C-578-14. In absence of clear building Codes and regulation in MENA region based on Low GWP BA,manufactures are at risk to be neither competitive nor economically feasible. They will have to bear penalty due to higher Lamda and higher density and will be under pressure to sustain business.

Thank You Thank You