Caterpillar Cat D7R TRACK-TYPE TRACTOR (Prefix 2HR) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models D7R TRACK-TYPE TRACTOR

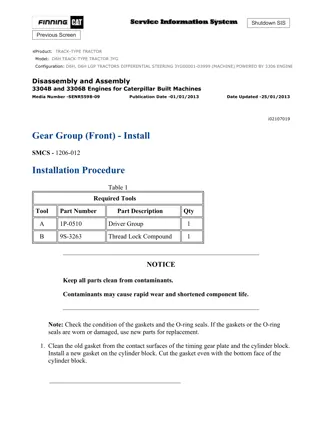

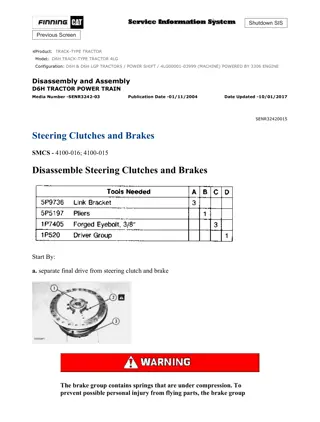

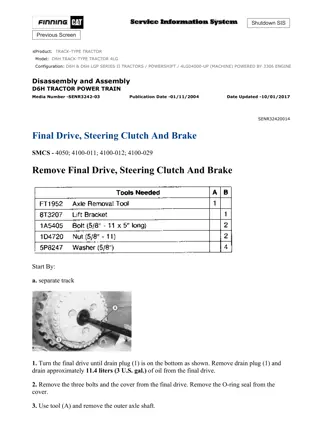

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 1/4 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D7R TRACK-TYPE TRACTOR 2HR Configuration: D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D7R Track-Type Tractor Power Train Media Number -SENR8342-03 Publication Date -01/06/2010 Date Updated -28/06/2010 i01596013 Final Drive, Steering Clutch and Brake - Install SMCS - 4050-012; 4100-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty 8T-3207 Lifting Bracket 1 5P-8622 Shackle 1 A 1D-4615 Bolt (3/4 inch by 10 by 5 1/2 inch) 2 1B-4331 Nut (3/4 inch by 10) 2 5P-8248 Washer 4 Without the sun gear in place, the brakes are ineffective. Personal injury or death could result. Provide other means to hold or stop the machine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 2/4 Illustration 1 g00827113 1. Adjust the top bracket of Tooling (A) until Dimension (X) is 76 mm (3.0 inch). Adjust the lower plate so that the spacers are oriented away from the vertical leg of the tool. Illustration 2 g00827167 2. Install O-ring seal (5) in the steering clutch and brake. Install O-ring seals (6) . Illustration 3 g00827165 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 3/4 3. Use Tooling (A) in order to install the final drive and the steering clutch and brake in the machine. The weight of the final drive, and the steering clutch and brake is approximately 775 kg (1700 lb). Illustration 4 g00827153 4. Install bolts (4) that hold the final drive, and the steering clutch and brake to the frame. Note: Bolts (2) hold the final drive and the steering clutch and brake together. 5. Install bolts (3) that hold the steering clutch and brake to the frame. Illustration 5 g00827135 6. Remove Tooling (A) from the final drive. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 4/4 Illustration 6 g00827132 7. Install bolts (1) in the sprocket segment. , End By: a. Install the axle. Refer to Disassembly and Assembly, "Axle - Remove and Install". b. Connect the track. Refer to Disassembly and Assembly, "Track - Separate". c. Fill the final drive with oil. Refer to Operation and Maintenance ManualSEBU7235, "Final Drive Oil Level - Check". Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 10 21:51:47 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 1/8 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D7R TRACK-TYPE TRACTOR 2HR Configuration: D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D7R Track-Type Tractor Power Train Media Number -SENR8342-03 Publication Date -01/06/2010 Date Updated -28/06/2010 i01569561 Steering Clutch and Brake - Disassemble SMCS - 4100-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 3 Start By: A. Separate the final drive from the steering clutch and from the brake. Refer to Disassembly and Assembly, "Final Drive, Steering Clutch, and Brake - Separate". Illustration 1 g00620422 1. Remove bolts (1) and plate (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 2/8 Illustration 2 g00620495 2. Remove sleeve bearings (3) from plate (2) . Illustration 3 g00620496 3. Remove input hub (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 3/8 Illustration 4 g00620498 4. Remove clutch plates (5) and friction discs (6) from hub (7) . Illustration 5 g00620499 5. Remove piston (8) from hub (7) . 6. Remove sleeve bearing (9) . Illustration 6 g00620501 7. Remove seals (10) and (11) from piston (8) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 4/8 Illustration 7 g00620502 8. Turn over the brake assembly. 9. Remove ring (12) from hub (7) . Illustration 8 g00620503 10. Fasten a hoist and Tooling (A) to housing (13). Remove the brake assembly from hub (7). The weight of the brake assembly is 86 kg (190 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 5/8 Illustration 9 g00620504 11. Remove bearing (14) from housing (13) . Illustration 10 g00620505 12. Remove three rings (15) from hub (7) . 13. Remove bearing (16) from the hub. Note: Bolts (19) hold a spring under compression behind the piston. Bolts (17) must be removed before bolts (19). Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 6/8 Illustration 11 g00620525 14. Remove bolts (17) and remove plate (18) from housing (13) . Illustration 12 g00620520 15. Remove brake plates (20) and friction discs (21) from the housing. Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. Note: Bolts (19) hold a spring under compression. Carefully loosen bolts (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 7/8 Illustration 13 g00620528 16. Remove bolts (19) and manifold assembly (22) from housing (13) . Illustration 14 g00620529 17. Remove seals (23) and (24) from manifold assembly (22) . Illustration 15 g00620530 18. Remove piston (25) from housing (13) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 8/8 Illustration 16 g00620531 Note: Note the direction of spring (26) before the spring is removed. 19. Remove spring (26) from housing (13) . 20. Remove O-ring seals (27) and (28) . Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 10 21:52:44 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 1/8 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D7R TRACK-TYPE TRACTOR 2HR Configuration: D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D7R Track-Type Tractor Power Train Media Number -SENR8342-03 Publication Date -01/06/2010 Date Updated -28/06/2010 i01569580 Steering Clutch and Brake - Assemble SMCS - 4100-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 3 B 1P-0510 Driver Group 1 1. Clean all the parts. Inspect all the parts for wear or for damage. If necessary, replace any parts that are worn or damaged. Illustration 1 g00620531 2. Install spring (26) in housing (13) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 2/8 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 3. Install O-ring seals (27) and (28) . Illustration 2 g00620530 4. Position piston (25) in housing (13) . Illustration 3 g00620529 5. Install seals (23) and (24) on manifold assembly (22). Install the seals on the manifold assembly with the lip of the seals in the position that is shown. Put clean oil on the lip of the https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 3/8 seals. Preload the seal rings before the installation procedure. This will prevent the seal rings from being damaged. Use the following method to preload the new seal rings. a. Place your hands on each end of the seal ring. Pull the ends past each other by several inches. The ends should almost make contact. Be careful to maintain the circular shape of the ring. This will make an even bend around the ring. b. When the seal ring is in the groove of the hub, the ends should lightly make contact. Do not bend the seal ring. This will make an uneven bend around the ring. Note: Do not use this procedure to preload a used seal ring. Do not use this procedure for cast iron seal rings. This procedure will cause used seal rings or cast iron seal rings to break. Illustration 4 g00620528 6. Align the oil holes in manifold assembly (22) with the holes in housing (13). Install the manifold assembly and install bolts (19) . Illustration 5 g00620505 7. Heat bearing (16) to a maximum temperature of 120 C (248 F). Use Tool (B) to install the bearing on hub (7). Be certain that the bearing is squarely seated on the hub after the bearing has cooled. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 4/8 8. Install three rings (15) on hub (7) . Illustration 6 g00620504 9. Install bearing (14) in housing (13) . Illustration 7 g00620759 10. Fasten a hoist and fasten Tooling (A) to housing (13). Lower the housing into the correct position on hub (7) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 5/8 Illustration 8 g00620502 11. Install ring (12) on hub (7) . Illustration 9 g00620520 12. Install brake plate (20). Install friction disc (21). Install the remaining brake plates and friction discs in an alternating fashion. Illustration 10 g00815087 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 6/8 13. Install plate (18) and bolts (17) on housing (13) . Illustration 11 g00620715 14. Install sleeve bearing (9) in hub (7) . Illustration 12 g00620501 15. Install seals (10) and (11) in piston (8) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 7/8 Illustration 13 g00620716 16. Put clean oil on the seals. Install piston (8) in hub (7) . Illustration 14 g00620717 17. Install input hub (4) . Illustration 15 g00620718 18. Install clutch plate (5). Install friction disc (6). Install the remaining clutch plates and friction discs in an alternating fashion. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 8/8 Illustration 16 g00620495 19. Install sleeve bearing (3) in plate (2) . Illustration 17 g00620422 20. Position plate (2) on the housing. Install bolts (1) . End By: Connect the final drive to the steering clutch and to the brake. Refer to Disassembly and Assembly, "Final Drive, Steering Clutch, and Brake - Connect" in this module. Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 10 21:53:41 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 1/2 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D7R TRACK-TYPE TRACTOR 2HR Configuration: D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D7R Track-Type Tractor Power Train Media Number -SENR8342-03 Publication Date -01/06/2010 Date Updated -28/06/2010 i01008366 Transmission and Bevel Gears - Separate SMCS - 3010-076 Procedure to Separate the Transmission and Bevel Gears Table 1 Required Tools Tool Part Number Description Qty A 1P-2420 Repair Stand for Transmissions 1 B 138-7575 Link Bracket 3 Start By: A. Remove the transmission and bevel gears. See the procedure in Disassembly and Assembly, "Transmission and Bevel Gears - Remove" in this module. Illustration 1 g00625502 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 2/2 Note: The transmission and bevel gears weigh 860 kg (1900 lb). 1. Install Tooling (A) on the bevel gear case. Attach a hoist. 2. Position the transmission and bevel gears on Tooling (B) . 3. Remove the four bolts that hold the transfer and bevel gears (1) to transmission (2) . Note: The transfer and bevel gears weigh 380 kg (850 lb). 4. Separate the transfer and the bevel gears from transmission (2) . Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 10 21:54:38 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 1/2 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D7R TRACK-TYPE TRACTOR 2HR Configuration: D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D7R Track-Type Tractor Power Train Media Number -SENR8342-03 Publication Date -01/06/2010 Date Updated -28/06/2010 i01008367 Transmission and Bevel Gears - Connect SMCS - 3010-077 Procedure to Connect the Transmission and Bevel Gears Table 1 Required Tools Tool Part Number Description Qty A 1P-2420 Repair Stand for Transmissions 1 B 138-7575 Link Bracket 3 1. Inspect the O-ring seals. Replace any seals that are damaged or worn. Install the O-ring seals on the transmission. Illustration 1 g00625502 Note: The transfer and bevel gears weigh 380 kg (850 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 2/2 2. Install Tooling (A) on the bevel gear case. Attach a hoist. 3. Position the transfer and bevel gears (1) on transmission (2) . 4. Install the four bolts that hold the transfer and bevel gears (1) to transmission (2) . Note: The transmission and bevel gears weigh 860 kg (1900 lb). 5. Remove the transmission and bevel gears from Tooling (B) . 6. Remove the hoist. Remove Tooling (A) from the bevel gear case. End By: Install the transmission and bevel gears. See the procedure in Disassembly and Assembly, "Transmission and Bevel Gears - Install" in this module. Copyright 1993 - 2021 Caterpillar Inc. Sat Apr 10 21:55:35 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 1/9 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D7R TRACK-TYPE TRACTOR 2HR Configuration: D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D7R Track-Type Tractor Power Train Media Number -SENR8342-03 Publication Date -01/06/2010 Date Updated -28/06/2010 i07141397 Bevel and Transfer Gears - Disassemble SMCS - 3011-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7575 Link Bracket 3 B 138-7575 Link Bracket 1 C 8H-0663 Bearing Puller 1 D 8T-2839 Spanner 1 E 1P-1863 Retaining Ring Pliers 1 1P-2321 Puller Assembly 1 F 5P-4170 Step Plate 1 G Forcing Screw (1/2 inch by 13) 2 H Bolt (1/4 inch by 20) 1 Start By: a. Separate the transmission and bevel gears. Note: Put identifying marks on all of the shims as the shims are removed. The identifying marks will ensure correct installation at assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 2/9 Illustration 1 g00504390 1. Remove bolts (1) and roller brackets (2) from each side of the transfer gear case. Illustration 2 g00504393 2. Remove bolts (4) that hold transfer gear case (3) to the bevel gear case. 3. Install Tooling (A) and attach a hoist to Tooling (A). Remove transfer gear case (3) from the bevel gear case. The weight of the transfer gear case is approximately 101 kg (223 lb). Illustration 3 g00839158 4. Remove bolts (5) that hold cage (6) to transfer gear case (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 3/9 5. Install Tooling (G). Tighten Tooling (G) evenly. Remove the cage and the shims from the transfer gear case. Illustration 4 g00830580 6. Remove lip seal (7) and O-ring seal (8) from cage (7). Illustration 5 g00504397 Note: The bearing cup and the bearing will be damaged if the bearing cups are removed. 7. Remove bearing cup (9) and bearing (10) from cage (6), if necessary. Illustration 6 g00504398 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 4/9 8. Remove transfer gear (11) from transfer gear case (3). Illustration 7 g00504399 Note: The bearing cones will be damaged if the bearing cones are removed from the transfer gear. 9. Remove bearing cones (12) from transfer gear (11), if necessary. Illustration 8 g00839162 10. Remove the bolts, and install Tooling (G) in cage (13). Tighten Tooling (G) evenly, and remove cage (13) and the shims from transfer gear case (3). 11. Remove bearing cup (14) from cage (13). 12. Remove bearing cup (15) from transfer gear case (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 5/9 Illustration 9 g00828209 13. Remove the bolt and the retainer from pinion gear assembly (17). Illustration 10 g00845891 14. Install Tooling (B) and attach a hoist. Remove pinion gear assembly (17) from the bevel gear case. The weight of the pinion gear assembly is approximately 33 kg (73 lb). 15. Remove the bearing cup for the pinion gear assembly from the bevel gear case. Illustration 11 g00845894 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 6/9 16. Put the pinion gear assembly in a press. Remove transfer gear (19) and bearing cone (18) from pinion gear (20). 17. Use Tooling (C) and a press to remove bearing cone (21) from pinion gear (20). Illustration 12 g00845898 18. Bend the locking tab away from spanner nut (23). 19. Place a pry bar between the bolt heads on the bevel gear. The prybar will prevent rotation of the bevel gear shaft. 20. Use Tooling (D) to remove spanner nut (23). Remove lockwasher (22) and the tongue washer. Illustration 13 g06234486 21. Use nylon straps and a hoist for support of the bevel gear and of the shaft to remove the bearings. The weight of the bevel gear and the shaft (24) is approximately 55 kg (121 lb). 22. If necessary, remove tube assemble (24A). Note: Note the orientation of tube assembly (24A) for installation purposes. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 7/9 Illustration 14 g00845906 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D7R Track-Type Tractor 2HR00001-UP (MACHINE) POWERED BY 3306 Engine(S... 8/9 Illustration 15 g00845909 23. Remove the bolts and install Tooling (G). Tighten Tooling (G) evenly and remove cage (25), bearing cone (27), spacer (28), and bearing cone (27). Remove shims (26) from the bevel gear case. 24. Remove the following components from cage (25): bearing cup (29), center ring (30) and bearing cup (29). Illustration 16 g00841204 25. Remove the bolts and Tooling (G). Tighten Tooling (G) evenly and remove cage (31) and the bearing from the bevel gear case. 26. Use a hoist and remove bevel gear and shaft (24) from the bevel gear case. Illustration 17 g00841205 27. Install Tooling (H), and remove dowel (33) from cage (31). Remove race and roller assembly (32). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/4/10

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com