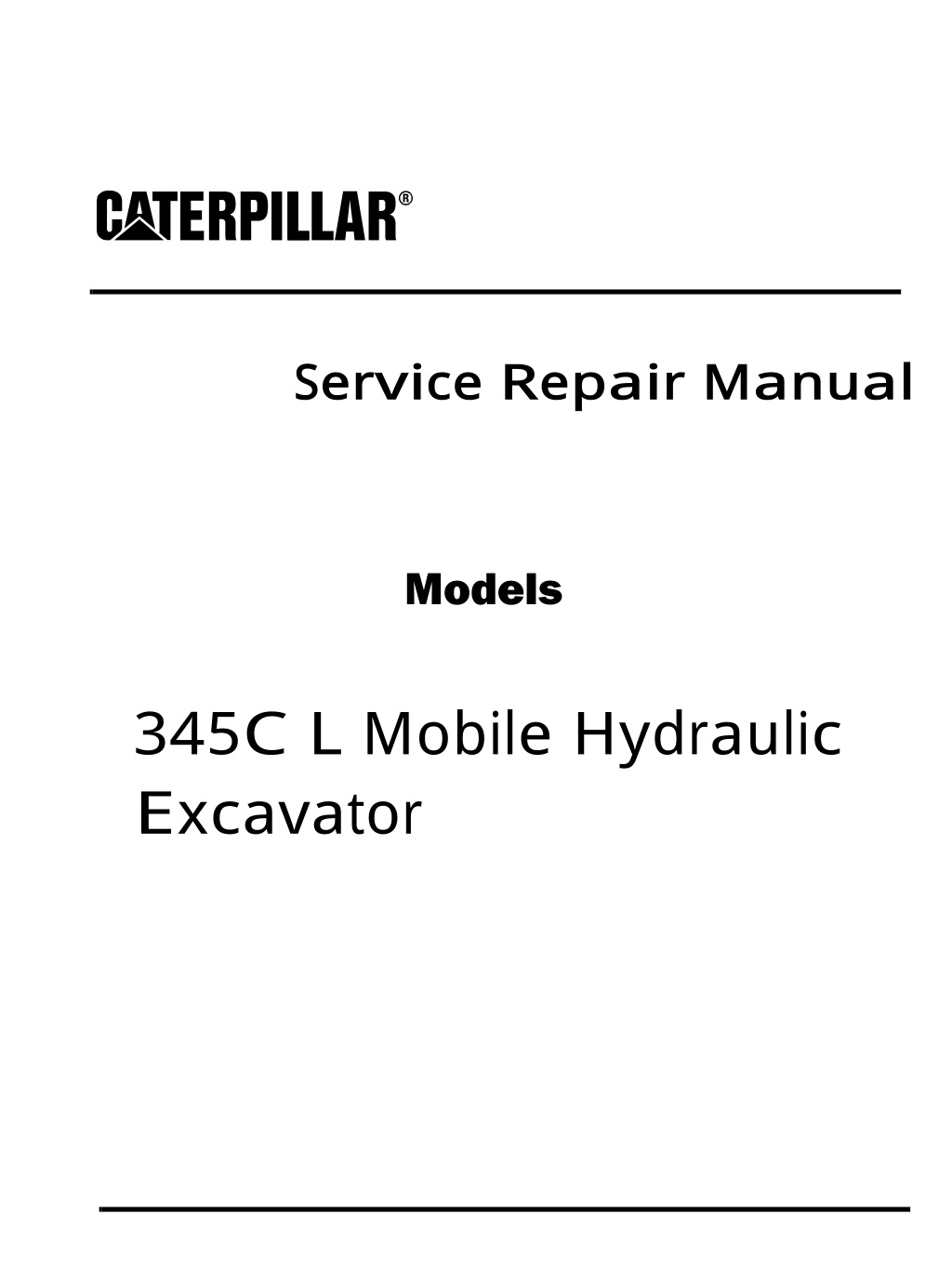

Caterpillar Cat 345C L Mobile Hydraulic Excavator (Prefix B6N) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

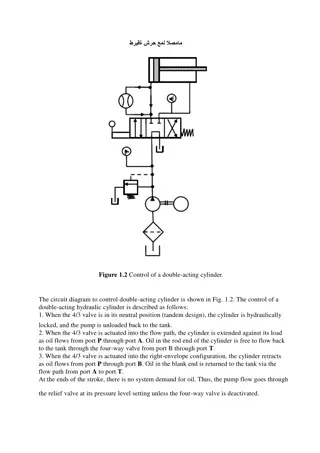

Presentation Transcript

Service Repair Manual Models 345C L M obile Hydraulic Excavator

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 1/7 Shutdown SIS Previous Screen Product: MOBILE HYD POWER UNIT Model: 345C L MOBILE HYD POWER UNIT B6N Configuration: 345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 345C MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -KENR6438-00 Publication Date -01/03/2007 Date Updated -19/03/2007 i03874214 Piston Motor (Hydraulic Fan) - Disassemble SMCS - 1386-015-QP; 5058-015-HFN; 5058-015-FM Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-1861 Retaining Ring Pliers 1 B 9S-9152 Bearing Puller Gp 1 Start By: A. Remove the motor. Refer to Disassembly and Assembly, "Piston Motor (Hydraulic Fan) - Remove". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 2/7 Illustration 1 g01175660 1. Remove bolts (1) and cover (2) . Illustration 2 g01175661 2. Remove O-ring seal (3) . Illustration 3 g01175662 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 3/7 3. Remove bolts (4) and head assembly (5) . Illustration 4 g01175663 4. Remove O-ring seal (6) and bearing cup (7) . Illustration 5 g01175664 5. Remove port plate (8) and bearing cone (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 4/7 Illustration 6 g01175665 6. Remove shim (10) and rotating assembly (11) . Illustration 7 g01175666 7. Remove shaft (12) and bearing cone (13) . Illustration 8 g01176865 8. Use a suitable press and Tooling (B) in order to remove bearing cone (13) from shaft (12) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 5/7 Illustration 9 g01175668 9. Remove swashplate (14) . Illustration 10 g01175727 10. Remove pistons (15) and retainer (16) . Illustration 11 g01175729 11. Remove bearing (17) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 6/7 Illustration 12 g01278723 12. Remove pins (18) . Illustration 13 g01278726 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 13. Use Tooling (A) and a suitable press in order to remove retaining ring (19) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 7/7 Illustration 14 g01278729 14. Remove washers (20) and spring (21) . Illustration 15 g02117134 15. Use Tooling (A) in order to remove retaining ring (22) . Remove lip seal (23) . Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 19:34:47 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 1/7 Shutdown SIS Previous Screen Product: MOBILE HYD POWER UNIT Model: 345C L MOBILE HYD POWER UNIT B6N Configuration: 345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 345C MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -KENR6438-00 Publication Date -01/03/2007 Date Updated -19/03/2007 i03874213 Piston Motor (Hydraulic Fan) - Assemble SMCS - 1386-016-QP; 5058-016-HFN; 5058-016-FM Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-1861 Retaining Ring Pliers 1 Illustration 1 g02117134 1. Install lip seal (23) . Use Tooling (A) in order to install retaining ring (22) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 2/7 Illustration 2 g01278760 2. Install washers (20) and spring (21) . Illustration 3 g01278756 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 3. Use Tooling (A) and a suitable press in order to install retaining ring (19) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 3/7 Illustration 4 g01278757 4. Install pins (18) . Illustration 5 g01175729 5. Install bearing (17) . Illustration 6 g01175727 6. Install pistons (15) and retainer (16) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 4/7 Illustration 7 g01175668 7. Install swashplate (14) . Illustration 8 g01175783 8. Raise the temperature of bearing cone (13) . 9. Install bearing cone (13) onto shaft (12) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 5/7 Illustration 9 g01175666 10. Install shaft (12) and bearing cone (13) . Illustration 10 g01175665 11. Install rotating assembly (11) and shim (10) . Illustration 11 g01175664 12. Install port plate (8) and bearing cone (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 6/7 Illustration 12 g01175663 13. Install O-ring seal (6) and bearing cup (7) . Illustration 13 g01175662 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 14. Install head assembly (5) and bolts (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 7/7 Illustration 14 g01175661 15. Install O-ring seal (3) . Illustration 15 g01175660 16. Install cover (2) and bolts (1) . End By: Install the motor. Refer to Disassembly and Assembly, "Piston Motor (Hydraulic Fan) - Install". Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 19:35:44 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 1/4 Shutdown SIS Previous Screen Product: MOBILE HYD POWER UNIT Model: 345C L MOBILE HYD POWER UNIT B6N Configuration: 345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 345C MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -KENR6438-00 Publication Date -01/03/2007 Date Updated -19/03/2007 i02427710 Piston Motor (Hydraulic Fan) - Install SMCS - 1386-012-QP; 5058-012-FM Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A FT-2674 Vacuum Cap 1 Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths or rags should not be used to dry parts. Lint may be deposited on the parts which may cause later trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. Illustration 1 g01213351 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 2/4 1. Use a suitable lifting device in order to position fan motor (9). The weight of fan motor (9) is approximately 25 kg (55 lb). Install bolts (11). Install fittings (10) . Illustration 2 g01213350 2. Connect hose assemblies (8). Install cover (7) . Illustration 3 g01213348 3. Install tubes (6). Install support (5) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 3/4 Illustration 4 g01213346 4. Use a suitable lifting device in order to install hood (3). The weight of hood (3) is approximately 68 kg (150 lb). Install bolts (4) . Illustration 5 g01213345 5. Close access panel (2) and install bolts (1) . 6. Close the front left access door. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 4/4 Illustration 6 g01213343 7. Remove Tooling (A) . Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 19:36:41 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 1/2 Shutdown SIS Previous Screen Product: MOBILE HYD POWER UNIT Model: 345C L MOBILE HYD POWER UNIT B6N Configuration: 345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 345C MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -KENR6438-00 Publication Date -01/03/2007 Date Updated -19/03/2007 i02554917 Hydraulic Lockout Control - Remove SMCS - 5001-011-LK Removal Procedure Illustration 1 g01187398 1. Remove screws (2) and panel (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 2/2 Illustration 2 g01278781 2. Remove screws (6). Cut cable strap (8) and place switch (7) aside. 3. Remove bolt (4), bolt (5), and hydraulic lockout control (3). Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 19:37:37 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 1/3 Shutdown SIS Previous Screen Product: MOBILE HYD POWER UNIT Model: 345C L MOBILE HYD POWER UNIT B6N Configuration: 345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 345C MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -KENR6438-00 Publication Date -01/03/2007 Date Updated -19/03/2007 i02378526 Hydraulic Lockout Control - Disassemble SMCS - 5001-015-LK Disassembly Procedure Start By: a. Remove the hydraulic lockout control. Refer to Disassembly and Assembly, "Hydraulic Lockout Control - Remove". Illustration 1 g01187382 Personal injury can result from being struck by parts propelled by a released spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 2/3 Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 1. Remove retaining rings (1) and lever assembly (2). 2. Remove retaining ring (4), lever assembly (5), and spring (3). Illustration 2 g01187383 3. Pull back cover (8) in order to remove pin (7) from pipe assembly (6). Illustration 3 g01187385 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

345C L Mobile Hydraulic Power Units B6N00001-UP (MACHINE) POWERED BY ... 3/3 Follow the recommended procedure and use all recommended tooling to release the spring force. 4. Remove pin (10) from pin (9). 5. Remove spring (11) from cover (12). Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 19:38:34 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com