Caterpillar Cat 336D2 and 336D2 L Excavator (Prefix WDC) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

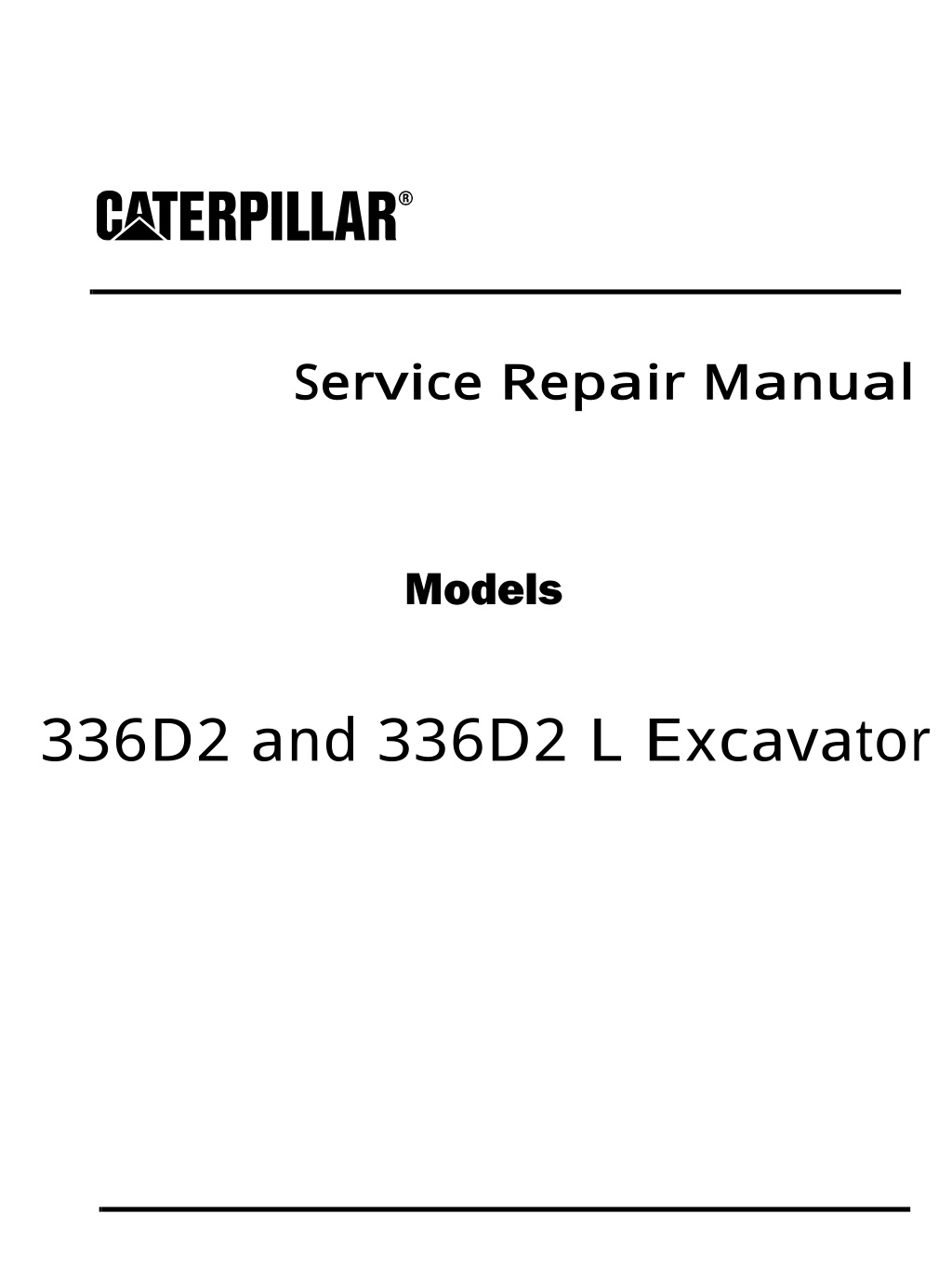

Service Repair Manual Models 336D2 and336D2L Excavator

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/7 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i02415273 Piston Motor (Hydraulic Fan) - Assemble SMCS - 1386-016-QP; 5058-016-FM; 5058-016-HFN Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty B 1P-1861 Retaining Ring Pliers 1 C 1P-0510 Driver Gp 1 Illustration 1 g01207288 1. Install bearing cup (29). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/7 Illustration 2 g01207286 2. Install lip seal (28). 3. Use Tooling (C) in order to install retaining ring (27). Illustration 3 g01207624 4. Raise the temperature of bearing cone (26). 5. Install bearing cone (26) onto shaft (25). Illustration 4 g01207285 6. Install shaft (25) and swashplate (24). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 3/7 Illustration 5 g01207283 Illustration 6 g01207284 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 7. Install shim (21), spring (22), and shim (23). 8. Use Tooling (C) and Tooling (B) in order to install retaining ring (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 4/7 Illustration 7 g01207282 9. Install pins (18). Illustration 8 g01207281 10. Install bearing (17). 11. Install pistons (15) and retainer (16). Illustration 9 g01207280 12. Install rotating group (14) and shim (13). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 5/7 Illustration 10 g01207279 13. Install bearing cone (12). Illustration 11 g01207278 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 14. Install O-ring seal (11), poppet (10), spring (9), poppet (8), sleeve (7), and plug (6). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 6/7 Illustration 12 g01207276 15. Lower the temperature of bearing cup (5). 16. Install bearing cup (5), port plate (4), and O-ring seal (3). Illustration 13 g01207275 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 17. Install head (2) and bolts (1). End By: a. Install the piston motor. Refer to Disassembly and Assembly, "Piston Motor (Hydraulic Fan) - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/2 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i02415453 Piston Motor (Hydraulic Fan) - Install SMCS - 1386-012-QP; 5058-012-FM installation Procedure Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths or rags should not be used to dry parts. Lint may be deposited on the parts which may cause later trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. Illustration 1 g01207418 1. Use a suitable lifting device to install piston motor (5). The weight of piston motor (5) is approximately 23 kg (50 lb). 2. Install bolts (6). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/2 Illustration 2 g01207416 3. Use a suitable lifting device to reposition fan motor assembly (4), as shown. The weight of fan motor assembly (4) is approximately 68 kg (150 lb). Illustration 3 g01207415 4. Install hub (3) and bolts (2). 5. Bend locking tabs (1) over bolts (2). End By: a. Install the fan. Refer to Disassembly and Assembly, "Fan - Install". Copyright 1993 - 2020 Caterpillar Inc. Mon Aug 10 23:59:03 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/10

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/2 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i02554917 Hydraulic Lockout Control - Remove SMCS - 5001-011-LK Removal Procedure Illustration 1 g01187398 1. Remove screws (2) and panel (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/2 Illustration 2 g01278781 2. Remove screws (6). Cut cable strap (8) and place switch (7) aside. 3. Remove bolt (4), bolt (5), and hydraulic lockout control (3). Copyright 1993 - 2020 Caterpillar Inc. Mon Aug 10 23:59:59 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/3 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i02378526 Hydraulic Lockout Control - Disassemble SMCS - 5001-015-LK Disassembly Procedure Start By: a. Remove the hydraulic lockout control. Refer to Disassembly and Assembly, "Hydraulic Lockout Control - Remove". Illustration 1 g01187382 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/3 Follow the recommended procedure and use all recommended tooling to release the spring force. 1. Remove retaining rings (1) and lever assembly (2). 2. Remove retaining ring (4), lever assembly (5), and spring (3). Illustration 2 g01187383 3. Pull back cover (8) in order to remove pin (7) from pipe assembly (6). Illustration 3 g01187385 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 3/3 4. Remove pin (10) from pin (9). 5. Remove spring (11) from cover (12). Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 00:00:55 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/3 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i02378527 Hydraulic Lockout Control - Assemble SMCS - 5001-016-LK Assembly Procedure Illustration 1 g01187385 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/3 1. Install spring (11) to cover (12). 2. Install pin (10) to pin (9). Illustration 2 g01187383 3. Install pin (7) to pipe assembly (6). 4. Slide cover (8) over pipe assembly (6). Illustration 3 g01187382 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 5. Install spring (3), lever assembly (5), and retaining ring (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 3/3 6. Install lever assembly (2) and retaining rings (1). End By: a. Install the hydraulic lockout control. Refer to Disassembly and Assembly, "Hydraulic Lockout Control - Install". Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 00:01:51 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/2 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i07426591 Hydraulic Lockout Control - Install SMCS - 5001-012-LK Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A - Loctite 243 - Illustration 1 g01278781 1. Install hydraulic lockout control (3), bolt (4), and bolt (5). 2. Apply Tooling (A) to the threads of screws (6). Position switch assembly (7) and install screws (6). Tighten screws (6) to a torque of 0.7 0.1 N m (6.2 0.9 lb in). Attach cable strap (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/2 Illustration 2 g01187398 3. Install panel (1) and screws (2). Copyright 1993 - 2020 Caterpillar Inc. Tue Aug 11 00:02:47 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 1/9 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 336D2 EXCAVATOR WDC Configuration: 336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engine Disassembly and Assembly 330D, 336D, 336D2, 340D and 340D2 Excavators and 336D MHPU Mobile Hydraulic Power Unit Machine Systems Media Number -RENR8648-30 Publication Date -01/03/2015 Date Updated -15/08/2018 i02417256 Operator Console - Remove and Install SMCS - 5258-010 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A FT-2674 Vacuum Cap 1 Start By: a. Remove the seat. Refer to Disassembly and Assembly, "Seat - Remove". Note: Put identification marks on all lines, on all hoses, on all wires, and on all tubes for installation purposes. Plug all lines, hoses, and tubes. This helps to prevent fluid loss and this helps to keep contaminants from entering the system. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 2/9 Illustration 1 g01208165 1. Remove plates (1) and (2). Illustration 2 g01196137 2. Attach Tooling (A) and an air supply to the hydraulic oil tank. Apply 345 70 kPa (50 10 psi) to Tooling (A). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 3/9 Illustration 3 g01208182 3. Disconnect hose assemblies (3). Illustration 4 g01208191 4. Disconnect hose assemblies (4). Illustration 5 g01208198 5. Disconnect harness assemblies (5). Illustration 6 g01208202 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 4/9 6. Disconnect harness assemblies (6). Illustration 7 g01208204 7. Remove plate (8). Move floor mat (7) toward the front of the cab. Illustration 8 g01208208 8. Remove bolts (9) from each side of the operator console. Pull hose assemblies (3) and (4) through the floor of the cab. Hose assemblies (3) and (4) were removed in Steps 3 and 4. Pull harness assemblies (5) and (6) through the floor of the cab. Harness assemblies (5) and (6) were removed in Steps 5 and 6. Note: If the machine is equipped with a radio, the antenna will need to be disconnected. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 5/9 Illustration 9 g01208250 9. Disconnect harness assembly (10). Illustration 10 g01208252 10. Remove bolts (11) and operator console (12). Installation Procedure Table 2 Required Tools Tool Part Number Part Description Qty A FT-2674 Vacuum Cap 1 Illustration 11 g01208252 1. Install operator console (12) and bolts (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 6/9 Illustration 12 g01208250 2. Connect harness assembly (10). Illustration 13 g01208208 3. Insert hose assemblies (3) and (4) through the hole in the cab floor. Insert harness assemblies (5) and (6) through the holes in the cab floor. Hose assemblies (3) and (4) and harness assemblies (5) and (6) will be connected in the following steps. Install bolts (9) from each side of the operator console. Note: If the machine is equipped with a radio, the antenna will need to be connected. Illustration 14 g01208204 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

336D2 & 336D2 L Excavators WDC00001-UP (MACHINE) POWERED BY C9 Engi... 7/9 4. Move floor mat (7) toward the rear of the cab. Install plate (8). Illustration 15 g01208202 5. Connect harness assemblies (6). Illustration 16 g01208198 6. Connect harness assemblies (5). Illustration 17 g01208191 7. Connect hose assemblies (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/8/11

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com