Bend or flexure testing

The significance and methods of flexure testing in assessing the strength and stiffness of brittle materials like composites, concrete, and ceramics. Learn about three-point and four-point bending tests, measurement parameters, and applications of flexural testing in material analysis.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

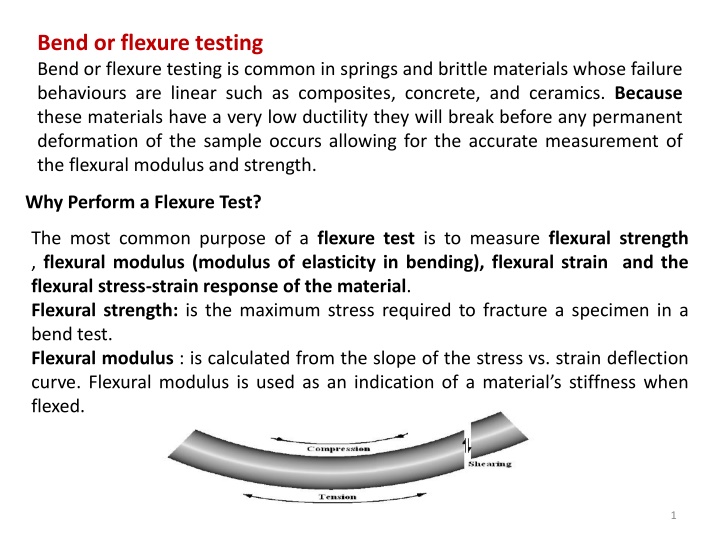

Bend or flexure testing Bend or flexure testing is common in springs and brittle materials whose failure behaviours are linear such as composites, concrete, and ceramics. Because these materials have a very low ductility they will break before any permanent deformation of the sample occurs allowing for the accurate measurement of the flexural modulus and strength. Why Perform a Flexure Test? The most common purpose of a flexure test is to measure flexural strength , flexural modulus (modulus of elasticity in bending), flexural strain and the flexural stress-strain response of the material. Flexural strength: is the maximum stress required to fracture a specimen in a bend test. Flexural modulus : is calculated from the slope of the stress vs. strain deflection curve. Flexural modulus is used as an indication of a material s stiffness when flexed. 1

Types of Flexure Test The two most common types of flexure test are three point and four point flexure bending tests as shown in figure 1. figure 1 2

Three Point Bending Test A three point bend test consists of the sample placed horizontally upon two points and the force applied to the top of the sample through a single point so that the sample is bent in the shape of a V . Four Point Bending Test A four point bend test is roughly the same except that instead of the force applied through a single point on top it is applied through two points so that the sample experiences contact at four different points and is bent more in the shape of a U . the maximum flexural stress is spread over the section of the beam between loading points. A four point test tends to be the best choice if the material is not homogeneous, such as composites or wood. The stress concentration of a four point test is over a larger region, avoiding premature failure. Therefore, the four point flexure test is more suited towards the testing of a large section of the sample, which highlights the defects of the sample better than a 3-point bending test A four point test more difficult than a three point test The four point bend test is commonly measured using a deflectometer. The highest or maximum bend stress occurs under the loading anvil a three point test best applies where the material is homogeneous, such as plastic materials The stress concentration of a three point test is small and concentrated under the center of the loading point . Therefore, the three point flexure test is ideal for the testing of a specific location of the sample A three point test is easy point test The deflection measurement in three point tests is commonly measured crosshead position sensor using the machine s 3

Where T = maximum bending moment J= moment of inertia of cross section C = distance from center of specimen to outer fibers F = applied load T c J Rectangular Circular 4

Elastic modulus is proportional to F/ Calculation of the flexural strain D= Depth or thickness of tested beam, (mm) = maximum deflection of the center of the beam, (mm) J C The benefits of bending test for the welded materials : 1. Physical condition of the weld 2. Determine welds efficiency 3. Flexural strength 4. Ductility 5. Fusion and penetration 5