Advancing Microbiological Systems Through Genetic Engineering and Microbial Community Engineering

Exploring the intersection of genetic engineering and microbial community engineering to enhance electron bifurcation systems. Addressing trade-offs between synthetic biology and wildtype organisms, incorporating microbial community engineering in Synbio, and investigating CO2 metabolism in the absence of light. Delving into microbial community metabolism, electron transfer processes, and the opportunities presented by mixed microbial communities. Highlighting challenges in understanding microbial dynamics, spatial structure of microbial cultures, and the potential for engineering microbiomes for value-added products from waste CO2. Emphasizing the need for advancements in fundamental systems biology and microbial kinetics to unlock the full potential of biotechnological applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

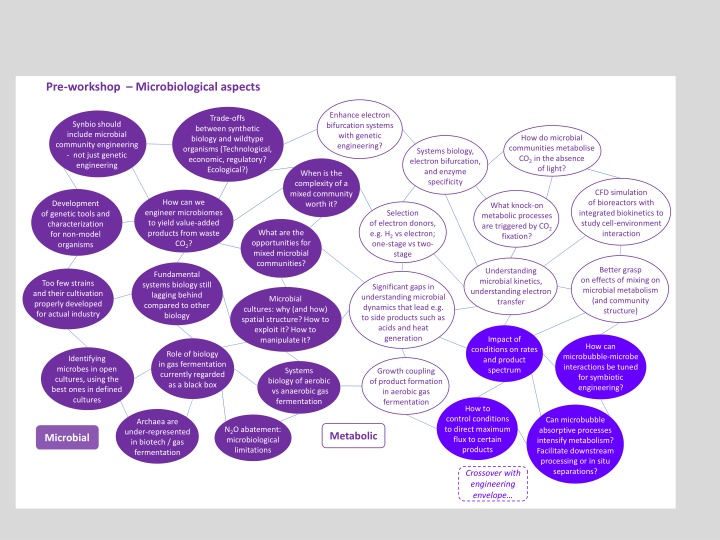

Pre-workshop Microbiological aspects Enhance electron bifurcation systems with genetic engineering? Trade-offs between synthetic biology and wildtype organisms (Technological, economic, regulatory? Ecological?) Synbio should include microbial community engineering - not just genetic engineering How do microbial communities metabolise CO2 in the absence of light? Systems biology, electron bifurcation, and enzyme specificity When is the complexity of a mixed community worth it? CFD simulation of bioreactors with integrated biokinetics to study cell-environment interaction How can we engineer microbiomes to yield value-added products from waste CO2? Development of genetic tools and characterization for non-model organisms What knock-on metabolic processes are triggered by CO2 fixation? Selection of electron donors, e.g. H2 vs electron; one-stage vs two- stage What are the opportunities for mixed microbial communities? Better grasp on effects of mixing on microbial metabolism (and community structure) Understanding microbial kinetics, understanding electron transfer Fundamental systems biology still lagging behind compared to other biology Too few strains and their cultivation properly developed for actual industry Significant gaps in understanding microbial dynamics that lead e.g. to side products such as acids and heat generation Microbial cultures: why (and how) spatial structure? How to exploit it? How to manipulate it? Impact of conditions on rates and product spectrum How can Role of biology in gas fermentation currently regarded as a black box microbubble-microbe interactions be tuned for symbiotic engineering? Identifying microbes in open cultures, using the best ones in defined cultures Systems Growth coupling of product formation in aerobic gas fermentation biology of aerobic vs anaerobic gas fermentation How to control conditions to direct maximum flux to certain products Can microbubble absorptive processes intensify metabolism? Facilitate downstream processing or in situ separations? Archaea are under-represented in biotech / gas fermentation N2O abatement: microbiological limitations Metabolic Microbial Crossover with engineering envelope

Pre-workshop Engineering envelope Hydrodynamics Can we use neural networks to improve gas mixing of microbial systems? Modelling flow & diffusion in reactors, through biofilm/electrode/ membrane Are particular equipment/reactor designs suited to particular organisms/ applications? Can reactor design for gas transfer move beyond empirically- based approaches? Concentration gradients in industrial- scale reactors, and how to mitigate or exploit them CO bioconversion: Limited gas-liquid transfer How do we predict (or even know) when enough (mass transfer) is enough? How much does it depend on application, organisms etc? What are critical design criteria for mass transfer/mixing systems? (given multiple process requirements) Physico-chemical barriers - poor solubility and gas-liquid mass transfer of H2 Reduced-order models for rapid assessment of heterogeneity & design optimisation Predictive models for kLa (especially a) in microbial broth Can CFD work across scales relevant to microbial environments? Mass transfer between gases and microbial cultures growing in a liquid phase or film Measuring H2 assisted CO2 bioconversion: Limited gas- liquid transfer Better tools for prediction & analysis of mass transfer concentration gradients in biofilms, and how to mitigate or exploit them Scale effects on gas transfer (and on microbial metabolism / performance) Impact of How do we know when mass transfer is limiting? (often difficult to measure intermediates) broth composition on hydrodynamics: How do components in the broth affect bubble size, mass transfer rates? CH4 abatement: Limited gas-liquid transfer, inhibition by metabolites On-line How do (local) concentrations of dissolved gases affect product spectrum, production rates Scale-up investment and infrastructure measurement of dissolved gas concentrations Bioreactor hydrodynamics: Experimental assessment of gas-liquid hydrodynamics in fermentation broths How do How much should we care that we only measure bulk/macroscopic characteristics, but microorganisms predominantly influenced by highly localised environmental conditions? fermentation broth properties (viscosity, surface tension etc) affect gas transfer characteristics? Scale-up inc. mixing and safety Mixing & mass transfer How to What are the mechanisms for microbubble microorganism interactions? control conditions to direct maximum flux to certain products Scale-up is Working at small pilot scale with flammable/ explosive gases limiting advancement particularly in 1-10 litre range Scale-down: Design of lab-scale setups to study impact of heterogeneous conditions on cells Scale-up

Identify key components in gas fermentation knowledge gaps - physiology, synbio methods, bioreactors, bioprocesses Trans- / inter-disciplinary working Pre-workshop Other Economics, Policy, Implementation Microbubble reactive-separations, say for removal of higher value-added molecules? Holistic overview and integration of knowledge is lacking Product generation as main goal vs augmented waste treatment Accommodating intermittent energy patterns while complying with various CO2 supplies Broader policies that take all these technologies into consideration Field is diverse with regard to industrially relevant organisms + processes: pressure, shear forces, growth media, productivity yields How do we separate products from liquors? Recovery of non-volatile products Process economy (and feedstock supply) in gas fermentation C1 products need to be competitive against existing industry Policy framework and investment climate not where it should be When is it useful (and how!) to switch between desired products, or between varying feedstocks? Integration with upstream processes Downstream processing: impact of hard-to-remove byproducts, product titre, etc on purification Gaseous feedstocks - mapping composition, scale, location Can enough CO2 be fixed as biomass in relation to ethanol/methane via Wood- Ljungdahl Pathway to generate biomass-derived platform chemicals in a commercially feasible way? Key questions on towards commercialisation not asked Need to utilise side- streams in gas fermentation What should we be making? From what? Utilizing side streams to enhance overall system efficiency Product diversification Gas quality variability Recycling microbial broth after downstream product removal Opportunities for detailed engineering appraisal and techno-economic assessment Gas recycles; impact of gas impurities; gas purification Industrial engagement/ funding Product diversification: metabolic engineering; metabolic models Gaseous feedstocks versus soluble (e.g. formate, methanol) How do we answer what-if questions in design & operation decisions? Process design & integration Feedstocks & Products

Workshop Microbiological aspects Microbial metabolites and their impact Metabolic Tools for mixed culture / community genetic engineering are immature/lacking. Warrants targeted development Understanding (i.e. predictive modelling) metabolic network dynamics within cells i.e. what determines cellular metabolic fluxes Understanding microbial inhibition during gas fermentation & designing mitigation strategies More genetic tools for non-model microbes Understanding (i.e. predictive modelling) microbial interactions among themselves and with the environment i.e. what determines microbe- environment & microbe- microbe interactions? Using AI/ Machine Learning to gain understanding of the organisms' metabolome / genome (need big datasets!) Significant potential to use non- model organisms has yet to be realised: much of prokaryotic tree of life ignored Don t ferment gases: pre-process into liquid feed then ferment Microbial community understanding Liquid/gas interactions with microbes Predictive modelling Complexity/links: genetic - community behaviour/outcome - physical engineering design Significant potential for microbial communities / mixed cultures but knowledge gaps as to their stability/engineerability (environmental & genetic) & optimal or pre-requisite complexity Developing and maintaining biofilms Symbiotic engineering of mixed culture consortia Crossover with engineering envelope Make research into microbiology both fundamentally interesting & makes a positive impact on the world Microbial

Workshop Engineering envelope In situ Process control & optimisation measurement of gas compositions in the aqueous phase Multi-scale models of liquid cultures, covering cells, biofilms/granules and the bulk that incorporate thermodynamics (metabolism) and hydrodynamics (flows & mass transfer) How to monitor, control and optimise the integration of the full production process towards more efficiency, sustainability and economy Complexity/links: genetic - community behaviour/outcome physical engineering design Fermenter monitoring and operating strategies Predictive models Engineering for better mixing & distributed kinetics (CFD-like modelling) Optimised reactor design to enhance substrate availability Exploit best of chemical (methanol) and biology (methylotrophy) as two- stage processing Modelling Development of better scale-driven models Gas transfer between gas - liquid - biomass New reactor designs (for gas - liquid bio) Mass transfer Mixing & mass transfer Development of high mass-transfer scalable gas phase bioreactors Fundamental understanding/ prediction of kLa values

Workshop Other Change biomass feedstock fermentation to biomass and H2 to make more efficient and faster How to reduce costs of sterile systems to allow lower value products to be economically viable How to stop making CH4 and start making more valuable and sustainable products from waste or air- capture CO2 Use of Optimisation of biofilms through CFD neural networks for optimisation of biomethanisation Look into dissolved forms of H2, CO2 (formate, methanol) Gas transfer mechanisms and repercussions for H2 and CH4 Funding Scale-up / demonstration facilities Developing new tools for the design of gas fermenters streams to support scaling-up Economic comparison of various waste feedstocks by AD and the combination of syngas fermentation Comparison of AD and gas fermentation for various feedstocks Cost- Funding for R&D and demo which has a longer horizon for planned returns -> UK as an innovation leader rather than follower benefit analysis of bioproduction methods for different classes of bioproducts e.g. bulk chemicals, high value, pharma How can we develop tools to model complex systems? Policy & Regulation (HSE) e.g. Clostridia Feedstock and product diversification Scale-up Cross- Integration with up/downstream and supply chains Follow-up is 'External' stuff (but not really) e.g. economics, funding, strategic interests, upstream Process selection for targeted products engagements/ education across disciplines/ approaches needed for the challenges and gaps we identify today. We should, 2 years from now, re- assess them to check for their progress Optimisation of feedstocks & recovery methods for selected bioproducts Feedstock, process, product Knowledge centralisation for competencies, progression-check, capabilities and opportunities Discussions about IP are the most complicated when establishing partnerships. More generalizable agreements would be nice to have Policy & Implementation

Too many papers "I ve a great model" but no shared implementation to play with Develop dataset formats that can allow 'anonymised' results to be collated for data mining on process data from a wide variety of fermentations Lack of agility in contracts / IP management in Universities Niche venture capital with whole sector 'ecology' experience Communication and understanding across disciplines Policy & implementation Knowledge transfer Lack of trust by investors in new technologies Identify or create business cases with real positive societal, environmental and economic impact Hyper-specialisation super-incentivised. Knowledge silos. We need generalists who speak engineering, biology, programming and economics Transparent reporting that facilitates comparison and sharing of data/ practice High cost of immigration to UK limiting global talent pool More targeted cross-disciplinary cross-sector funding opportunities More accurate and improved scale-down models Talent - acquisition/ retention Scale-up Promoting collaborative projects between industry and academia Feedstock/Process/ Product Further For progress: open competitive challenges, e.g. in the same spirit as 'Protein structure prediction competition development/investment in open access scale-up facilities dedicated to gas fermentation Honest/open discussion of what bioprocess/ product to focus on Sustainability and environmental impacts Funding support for scale-up Scale-up Expert H&S / Hazop / HazID support Markets & logistics More targeted funding support to move technological/ Integration readiness levels upwards Instrumentation/ equipment access at laboratory level dispersed across Universities nationally Mapping of feedstock availability, composition, quality More coordination between feedstock suppliers Safe and cheap relevant research and development facilities Workshop actions and obstacles

Summary of key R&D priorities Follow-up to assess progress on challenges Actions Increased support for scale- up (construction of and access to facilities) Initiatives for better data accessibility and sharing of expertise/ facilities Effective designs for bioreactor manufacture and operation Microbial More agile arrangements for university/industry collaboration and IP Data for Multi-scale mechanistic models, including metabolic and hydrodynamic aspects, to de-risk scale up Cross-sector & cross-remit funding for interdisciplinary collaboration development of multi- scale mechanistic and predictive modelling tools Scale-up studies, including influence of scale effects and development of reliable scale-down models Predictive modelling tools leveraging AI, machine learning & big data New tools for genetic characterisation and manipulation of non-model organisms Process integration and optimisation with up, down & sidestream components Support for economic and business models to improve investor confidence Systems biology of unique microbes and microbial communities, & metabolic responses to their environment Hydrodynamics of bioreactor mixing and mass transfer for process intensification Process Product selection and diversification monitoring tools (e.g. for dissolved gases and concentration gradients) as a basis for control & optimisation Exploration of more diverse (i.e. non- model) microbial species & communities Other Feedstock mapping & characterisation of production facilities Gas-liquid-biomass interactions and microbial inhibition mechanisms Rheology of complex multiphase liquids and its influence on gas & mass transfer Engineering envelope