Advanced Hybrid Electrochemical Machining Processes

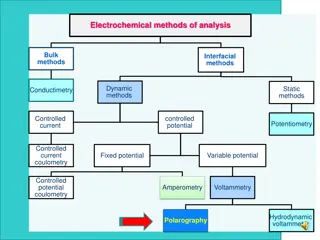

Hybrid electrochemical machining processes combine chemical dissolution and electrochemical dissolution mechanisms with mechanical or thermal assistance to achieve high material removal rates and improved surface quality. Techniques such as laser-assisted chemical etching and ultrasonic-assisted machining enhance the productivity of these processes by intensifying the dissolution phase. Additionally, the introduction of mechanical machining phases helps in changing interelectrode gap conditions, ensuring effective material removal and surface smoothening. Electrochemical grinding is another technique where a specially constructed grinding wheel is used as a cathode to achieve precise machining results.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

MENG584 Advanced Manufacturing Processes Presented by: Assist. Prof. Dr. Mohammed. Asmael

Hybrid Electrochemical Processes

Introduction In the hybrid electrochemical machining processes, the major material removal mechanism is either chemical dissolution (CD) or electrochemical dissolution (ECD). These machining processes are enhanced by using mechanical machining action or thermal assistance. The combination of these phases leads to high material removal rates and improved surface quality.

Introduction In the case of the thermally assisted processes using a laser beam (LB), the local heating of the interelectrode gap enhances the dissolution process in -laser-assisted chemical etching (LAE) or - laser-assisted electrochemical machining (ECML) during which the current density rises and the dissolution phase becomes more intensive leading to a more productive machining process

Introduction The introduction of a mechanical machining phase assists electrochemical machining (ECM) removal rates by changing the interelectrode gap conditions for the enhanced dissolution process. Under such conditions mechanical depassivation of the machined surface, by removing thin layers of oxides and other compounds from the anode, is ensured. This makes the surface dissolution and hence the smoothening process more intensive

Introduction Furthermore, ultrasonic-assisted electrochemical machining (USMEC) employs an ultrasonic (US) machining component with ECD to improve electrolyte flushing and hence the material removal rate. The mechanical action of the fluid jet (FJ) enhances the CD during electrochemical buffing (ECB).

Hybrid electrochemical processes. Electrochemical buffing

Electrochemical Grinding Electrochemical grinding (ECG) utilizes a negatively charged abrasive grinding wheel, electrolyte solution, and a positively charged workpice. The process is, therefore, similar to ECM except that the cathode is a specially constructed grinding wheel instead of a cathodic shaped tool like the contour to be machined by ECM. The insulating abrasive material (diamond or aluminum oxide) of the grinding wheel is set in a conductive bonding material.

Electrochemical Grinding In ECG, the nonconducting abrasive particles act as a spacer between the wheel conductive bond and the anodic workpiece. Depending on the grain size of these particles, a constant interelectrode gap (0.025 mm or less) through which the electrolyte is flushed can be maintained.

Material removal rate When a gap voltage of 4 to 40 V is applied between the cathodic grinding wheel and the anodic workpiece, a current density of about 120 to 240 A/cm2 is created. The current density depends on the material being machined, the gap width, and the applied voltage. Material is mainly removed by ECD, while the MA of the abrasive grits accounts for an additional 5 to 10 percent of the total material removal. Removal rates by ECG are 4 times faster than by conventional grinding, and ECG always produces burr-free parts that are unstressed.

Material removal rate The work of the abrasive grains performs the mechanical depolarization by abrading the possible insoluble films from the anodic workpiece surface. Such films are especially formed in case of alloys of many metals and cemented carbides. A specific purpose of the abrasive grains is, therefore, to depassivate mechanically the workpiece surface. In the machining zone there is an area of simultaneous ECD and MA of the workpiece surface, where the gap width is less than the height of the grain part projecting over the binder. Another area of pure electrochemical removal where the abrasive grains do not touch the workpiece surface exists at the entry and exit sides of the wheel.

Material removal rate The increase in performance of the ECG process results from interactions between MA, ECD, and changes in surface layer properties of material in the machining area. The increase in longitudinal feed rate and wheel speed and the decrease in voltage result in a smaller gap width and, consequently, in an increase in the MA contribution to the metal removal process. A decrease in the feed rate is followed by a considerable reduction in cutting forces, down to the values near zero at the transition to pure ECD.

Material removal rate Generally slow feed rates produce larger overcut, poor surface finish, and wider tolerances, while excessive wheel wear occurs as a result of a feed rate that is too fast. Use of expensive diamond grinding wheels considerably reduces the grinding forces which in turn significantly reduces the abrasive wear and provides notable savings in machining costs. The MA phase increases the process productivity, dimensional accuracy, and surface integrity while also reducing energy consumption.

Material removal rate Machining conditions at which the MA disappears depend on the electrical parameters, electrochemical machinability of the material in a given electrolyte, and grinding wheel features, especially grain size and height.

Accuracy and surface quality Traditional grinding removes metal by abrasion, leaving tolerances of about 0.003 mm and creating heat and stresses that make grinding thin stock very difficult. In ECG however a production tolerance of 0.025 mm is easily obtainable. Under special circumstances a tolerance of 0.008 mm can be achieved. Accuracies achieved are usually about 0.125 mm. It is recommended that lower voltages be used for closer tolerances, reduced overcut, sharp edges, and a bright surface finish.

Applications 1. Machining parts made from difficult-to-cut materials, such as sintered carbides, creep-resisting (Inconel, Nimonic) alloys, titanium alloys, and metallic composites. 2. Applications similar to milling, grinding, cutting off, sawing, and tool and cutter sharpening. 3. Production of tungsten carbide cutting tools, fragile parts, and thin-walled tubes. 4. Removal of fatigue cracks from steel structures under seawater. 5. Producing specimens for metal fatigue and tensile tests. 6. Machining of carbides and a variety of high-strength alloys.

Advantages Absence of work hardening Elimination of grinding burrs Absence of distortion of thin fragile or thermosensitive parts Good surface quality Production of narrow tolerances Longer grinding wheel life

Disadvantages Higher capital cost than conventional machines Process limited to electrically conductive materials Corrosive nature of electrolyte Requires disposal and filtering of electrolyte

Electrochemical Honing Conventional superfinishing by vibration grinding is a microfinishing operation in which the surface mirco- irregularities are removed by the continuous and slow reciprocation of abrasive sticks that move along the workpiece length. This process is however known to sustain some of the surface microirregularities such as waviness and out of roundness. In electrochemical superfinishing (ECS), the combination of electrolytic dissolution (ECD) and mechanical scrubbing (MS) improves the performance of the conventional superfinishing process.

Electrochemical Honing As a result of such a combination, the dissolution process assists the small stock removal rate due to the mechanical chipping action. The high stock removal capabilities combined with the ability to generate close dimensions gave high merits to the ECS process in all fields of industry.

Material removal process In ECS the dissolution action is accompanied by the formation of a protective oxide film on the anodic surface. These spots, with fresh metal contacting the electrolyte, will be subjected to a heavier ECD phase compared to areas still covered with the protective film.

Material removal process The power of the oxide film depends on the electrolyte used. Some electrolytes possess fairly strong power to reduce the ECD with their protective film. Other electrolytes have a strong protective film too, but the electric charge needed to build up the film is too small. In order to avoid metallurgical damage that may occur by mechanical scrubbing, light stone pressure is used after ECM to produce a bright surface finish, tolerances of about 0.013 mm on the diameter, and a roundness and straightness of less than 0.007 mm.

Material removal process The process variables include all those related to ECM parameters, such as gap concentration, and temperature. Regarding the MA, stone pressure, oscillation frequency, and amplitude besides the abrasive grain characteristics markedly affect the process performance. voltage, type, electrolyte

Process accuracy reduction of roundness error from 24 to 8 m during 2 min of machining using 19 V, a 67 percent duty cycle, and a scrubbing speed of 18.55 m/min. Similarly, surface roughness has been decreased from 2.25 to 0.65 m