Understanding Wettability Alteration in Thiolene-Based Polymers

This study explores the surface characterization and advanced fabrication techniques related to wettability alteration in thiolene-based polymers. It delves into the importance of wettability in multiphase flow applications at small scales, highlighting motivations and various techniques used to manipulate wettability, such as different fluid-fluid pairs and physical treatments like oxygen plasma and corona discharge.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Wettability alteration in thiolene-based polymers: surface characterization and advanced fabrication techniques M. Masouminiaand B. Zhao Department of Civil Engineering, McMaster University Department of Civil Engineering McMaster University March 4th 2022

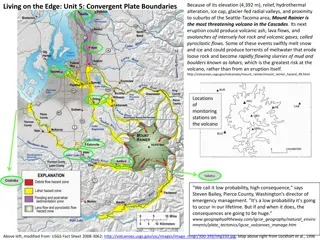

Multiphase flow at the small Multiphase flow at the small- -scale is important in many natural and industrial applications many natural and industrial applications scale is important in Motivation Vadose zone hydrology Carbon capture and storage (CCS) Enhanced oil recovery Holden et al., Encyclopedia of Soils in the Environment,, 2005 Haszeldine et al., Science, 2009 Nwidee et al., cEOR, 2016 1

Microfluidics offer a powerful experimental platform to Microfluidics offer a powerful experimental platform to study multiphase flow at the small scale study multiphase flow at the small scale Motivation Chen, Exp. Fluids, 1987 Kim et al., Lab Chip, 2013 Rabbani et al., PNAS, 2019 2

Wettability is an important property of multiphase flow Wettability is an important property of multiphase flow at the small scale at the small scale Motivation Wettability is a measure of a fluid s affinity to a solid surface in the presence of another fluid. Water is wetting to this countertop (relative to the ambient air) Water is non-wetting to this leaf (relative to the ambient air) 3

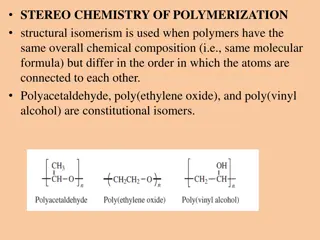

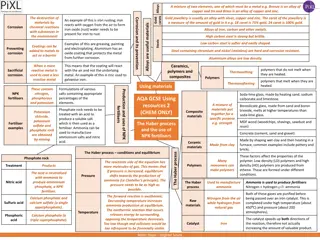

Different techniques have been introduced to tune Different techniques have been introduced to tune the wettability of microfluidic devices the wettability of microfluidic devices Using different fluid-fluid pairs Chemical vapor deposition (CVD) Using different fluid-fluid pairs Silverio et al., Colloids Surf, A Physicochem Eng Asp, 2019 Golmohammadi et al., Water Resour. Res., 2021 4

Different techniques have been introduced to tune Different techniques have been introduced to tune the wettability of microfluidic devices the wettability of microfluidic devices Motivation Oxygen plasma Corona discharge Tan et al., Biomicrofluidics, 2010 Davies et al., J Micromech Microeng, 2012 5

NOA81 is a promising material for fabricating surfaces NOA81 is a promising material for fabricating surfaces with controlled wettability with controlled wettability Motivation NOA81 (Norland Optical Adhesives) is a photocurable polymer. Exposure to high-energy UV makes the NOA81 surface more hydrophilic. The wettability can be continuously tuned over a wide range of contact angles by varying the duration of high-energy UV exposure. Levach , PRL, 2014 Zhao et al., PNAS, 2016 Despite the growing popularity of NOA81 in microfluidic studies, the physical and chemical mechanisms behind the UV-induced wettability alteration have not been characterized. 6

Existing devices are made with replica molding Existing devices are made with replica molding A drop of NOA 81 is sandwiched between two PDMS molds and cured with a UV light source. The top PDMS mold is removed and reveal a negative complement of the mold. Bartolo, Lab Chip, 2008 7

Surface topology of NOA81 film Surface topology of NOA81 film We use atomic force microscopy (AFM) to measure surface roughness of NOA81 surfaces. Replica molding yields very uniform NOA81 surfaces. Spin coating method achieves a smoother NOA81 surface. Spin-coating Replica molding RMS roughness = 1.32 nm Correlation length = 0.95 m RMS roughness = 0.59 nm Correlation length = 0.6 m 8

High High- -energy UV makes NOA81 surface more hydrophilic energy UV makes NOA81 surface more hydrophilic Develop an experimental platform to generate linear wettability gradient We measure the static advancing contact angle of water on spin-coated NOA81 surface in the presence of air and silicone oil. Contact angle of water in silicone oil Exposure time: 0 min ? = 117? Exposure time: 30 min ? = 18? 9

NOA81 surface characterization NOA81 surface characterization Characterization of NOA81 surface to investigate the wettability alteration of NOA81 due to the high-energy UV: X-ray photoelectron spectroscopy (XPS) Atomic force microscopy (AFM) 10

Characterize the surface chemistry by X-ray photoelectron spectroscopy (XPS) A quantitative technique for measuring the elemental composition of the surface. X-rays are shot onto a sample, and when electrons in the sample absorb enough energy, they are ejected from the sample with a certain kinetic energy. The energy of those ejected electrons is analyzed by a detector. 11 Smart et al., physics.uwo.ca/XPS, 2013

XPS analysis shows high XPS analysis shows high- -energy UV irradiation generates energy UV irradiation generates polar functional groups on NOA81 surface polar functional groups on NOA81 surface Increase in the oxygen content and decrease in carbon content, which increase the polar oxygen containing functional groups on the UV-modified NOA81 surface. Increase in polar groups for the UV-modified NOA81 makes it more hydrophilic. Full spectra Unmodified UV-modified 30 min 12

XPS analysis shows high XPS analysis shows high- -energy UV irradiation generates energy UV irradiation generates polar functional groups on NOA81 surface polar functional groups on NOA81 surface Unmodified UV-modified 30 min C1s spectra Increase in carboxyl (-COOH), ether (C-O), and amine (C-N), polar functional groups. Emergence of the carbonyl (C=O) polar functional group. Decrease in the hydrocarbon (C C/C H) non-polar functional group. S2p spectra Increase in sulfonate (SO3-H) and sulfone (-SO2) polar functional groups. Decrease in the sulfide (C-S-C), slightly polar functional group, and the thiol (C-S-H) non-polar functional group. 13

AFM measurement shows high AFM measurement shows high- -energy UV irradiation makes the NOA81 surface smoother the NOA81 surface smoother energy UV irradiation makes Unmodified UV-modified 30 min RMS roughness: 0.61 nm RMS roughness: 0.37 nm 14

Wettability gradient naturally arises in many subsurface applications Wettability gradient naturally arises in many subsurface applications In soils, wettability gradient arises via the diffusion of bio-surfactants produced by bacterial colonies. In enhanced oil recovery, wettability gradient arises via the diffusion of surfactants. Yao et al., Adv. Colloid Interface Sci., 2021 Yang et al., PNAS, 2021 15

An experimental platform to fabricate surfaces An experimental platform to fabricate surfaces with controlled wettability gradient with controlled wettability gradient We use a moving polyethylene terephthalate (PET) mask that locally blocks high-energy UV. The wettability gradient steepness could be manipulated along the surface by changing the mask speed. 16

Conclusion Conclusion We investigate the chemical and physical mechanism behind wettability alteration of NOA81 due to the high-energy UV exposure, which reveals that NOA81 offers excellent properties to fabricate microfluidic devices with controlled wettability. The wettability alteration by high-energy UV is mainly due to the chemical composition variations, while the changes in surface roughness are insignificant. Engineering NOA81 properties with more sophisticated fabrication techniques can extend its potential applications. The smooth surface of NOA81 provides a great option for fabricating chemical wettability gradient in microfluidic devices. masoumm@mcmaster.ca