What to Expect & Avoid At a Candle Making Class in NYC

Embark on a creative journey in NYC with candle making classes, offering millennials an engaging hobby. Expect expert guidance on fragrance oil ratios, wick sizes, and wax solidification times. Avoid common pitfalls like inadequate fragrance oil, uniform wick usage, and rushing the process. Perfect

19 views • 26 slides

Permanent-Mold Die Casting Processes Overview

Permanent-mold die casting is a process where molten metal is injected into a mold cavity under high pressure, maintained during solidification. This process utilizes hot-chamber and cold-chamber die casting machines for casting various metals like zinc, aluminum, brass, and magnesium. Hot-chamber m

4 views • 7 slides

Understanding Solidification Process in Metal Casting

Solidification in metal casting involves nucleation and growth processes, impacting the final product's quality. Factors such as type of metal, thermal properties, and mold shape influence solidification. Homogeneous nucleation occurs below the equilibrium freezing point, while heterogeneous nucleat

1 views • 8 slides

Development of Microstructure in Lead-Tin Eutectic Alloys

Different microstructures can form in lead-tin eutectic alloys, based on composition and cooling rate. The article explores various scenarios of solidification in lead-tin systems, highlighting the phases and structures that evolve at different compositions and temperatures. It discusses the phases

0 views • 7 slides

Understanding Rocks and Minerals: Types and Formation

Rocks and minerals are natural substances with distinct characteristics. Rocks are solid aggregates of minerals or mineraloids, while minerals are naturally occurring chemical compounds. There are three main types of rocks: igneous, sedimentary, and metamorphic, each formed through different process

0 views • 16 slides

Understanding Structural Steels and Designation Systems in the Industry

Structural steels play a crucial role in various industries, with specific requirements like strength, toughness, weldability, and corrosion properties. The designation and grouping systems help classify metallic materials and welding consumables according to standards set by organizations like the

0 views • 12 slides

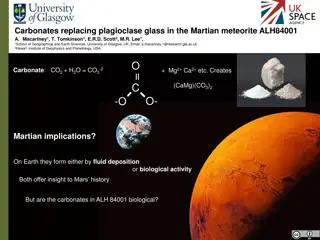

Carbonates Replacing Plagioclase Glass in Martian Meteorite ALH84001

The carbonates replacing plagioclase glass in the Martian meteorite ALH84001 have raised questions about their origin - whether they are biologically formed or through other geological processes. Discovered in Antarctica in 1984, this meteorite has been dated to over 4 billion years and initially mi

0 views • 14 slides

Understanding Classification of Discontinuities in Metal Processing

Classification of discontinuities in metal processing involves identifying interruptions in the normal physical structure, such as cracks, seams, and inclusions, which may or may not be defects. Discontinuities can be surface or subsurface, with surface ones being more likely harmful. The origins of

0 views • 29 slides

Understanding Heat Transfer in Phase Changes of Water

Water molecules exhibit different behaviors in the liquid and gaseous states due to varying attractions between molecules. To change liquid water to a gas, energy must be added to overcome intermolecular forces, making this process endothermic. The heat absorbed during melting is equal to the heat r

0 views • 22 slides

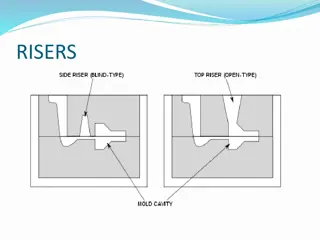

Understanding Risers and Casting Defects in Metal Casting Process

Risers are crucial in reducing shrinkage problems during casting by promoting directional solidification. Open versus blind risers have distinct characteristics affecting feeding and positioning within the mold. Rapid cooling rate and use of insulating compounds impact the efficiency of casting, whi

0 views • 41 slides

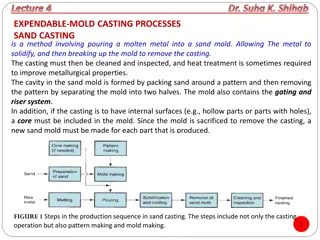

Expendable-Mold Casting Processes in Sand Casting: Lecture Insights

Sand casting is a process wherein molten metal is poured into a sand mold, left to solidify, and then the mold is broken to retrieve the casting. This casting method involves pattern making, mold creation, and uses a gating and riser system for complex geometries. Riser design is crucial in managing

0 views • 9 slides