Pharmaceutical Processing Equipment Market

Pharmaceutical processing includes a range of unit operations such as blending, milling, granulation, tablet pressing, coating, and filling, depending on the mode of delivery. With the growing adoption of continuous manufacturing and the rising number of novel therapies in clinical development, phar

1 views • 2 slides

Understanding Repair by Connective Tissue in Healing Processes

Healing or repair by connective tissue occurs in response to severe or chronic tissue injuries, leading to the replacement of nonregenerated cells with connective tissue or scar formation. This process involves the induction of fibroblast and endothelial cell proliferation, granulation tissue format

3 views • 26 slides

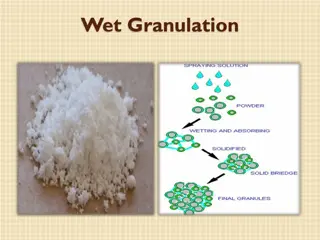

Wet Granulation Method in Industrial Pharmacy: Steps and Advantages

Wet granulation method in industrial pharmacy involves weighing and mixing ingredients, preparing a damp mass, converting it into wet granules, drying, dry screening, and mixing with lubricants. This method improves flowability, cohesiveness, and compressibility of powders, making them easily compre

0 views • 9 slides

Understanding Wound Healing Process by Secondary Intention

Exploring the stages and characteristics of wound healing by secondary intention, including open wounds, infection risks, necrosis, and non-suturing methods. Learn about the initial, inflammatory, granulation tissue formation, wound contraction stages, as well as potential complications like pigment

0 views • 12 slides

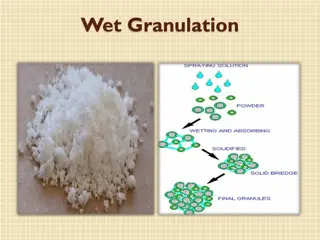

Wet Granulation Technique Overview

Wet granulation is a pharmaceutical technique involving wet massing, wet screening, and drying in addition to the standard steps of direct compression. It includes mixing the drug, diluent, and disintegrant, wet massing with a binder, granulation through wet sieving, and drying. The process ensures

1 views • 23 slides

Understanding Dry Granulation Techniques in Industrial Pharmacy

Dry granulation is a crucial process in industrial pharmacy where primary powder particles are agglomerated to form granules, offering various benefits such as preventing segregation, improving flow properties, and enhancing compaction characteristics. Secondary reasons for granulation include reduc

0 views • 18 slides

Overview of Tablet Compression Processes and Granulation Methods

Powders for tablet compression must have good flowability and compressibility properties. Techniques like slugging and dry compaction are used in the production of tablets by compacting powders into granules. Dry granulation may lead to fines or non-compacted products, requiring cohesive properties.

0 views • 11 slides

Understanding Wet Granulation Technique in Pharmaceutical Manufacturing

Wet granulation is a process in pharmaceutical manufacturing that involves wet massing, wet screening, and drying in addition to the traditional steps of direct compression. It includes mixing the drug, diluent, and disintegrant, wet massing with a binder, granulation, drying, and homogenizing befor

0 views • 23 slides

Understanding Granulation Methods in Tableting: A Comprehensive Overview

This information-rich material delves into the granulation methods in tableting, highlighting the aim of granulation to prevent segregation, improve flow properties, enhance compaction characteristics, reduce hazards of toxic dust, and prevent caking. It explores the wet granulation method, the role

0 views • 15 slides

Exploring the Structure and Phenomena of the Sun

Discover the intricate balance and core structure of the Sun, maintained by hydrostatic equilibrium. Energy moves through radiation and convection zones, with convection manifesting as granulation on the photosphere. Eclipses, such as solar eclipses, provide unique opportunities to witness celestial

0 views • 12 slides

Grinding and Granulation Equipment for Wood Pellets Production

For sale: New press KAHL for wood pellets production, designed for a 5-ton output per hour. The system includes grinding, moistening, granulation, and cooling of end products, fully integrated into a production cycle. This equipment line is located in Lithuania and ready for immediate operation, off

0 views • 5 slides

Understanding Tablet Production Methods and Properties

Tablet production techniques such as direct compression and granulation are essential steps involving powder milling, mixing, and tabletting. The use of crystalline structures and disintegrants impact the compressibility and flowability of tablets. Not all materials are suitable for direct compressi

0 views • 18 slides