Understanding Dobby Shedding in Fabric Manufacturing

Dobby shedding is a technique in fabric manufacturing using a shedding device on a loom to create intricate designs. It offers design possibilities like Twill, Satin, Crepe, and more. Contrasted with tappet shedding, dobby shedding is more intricate but requires more power and operates at lower spee

2 views • 18 slides

The Impact of Industrial Revolution on Society

The Industrial Revolution, spanning from 1760 to 1870, revolutionized manufacturing processes, transitioning from hand production to machines, introducing new chemical and iron production methods, and the use of steam power. It began in England and caused radical societal changes, leading to the ris

1 views • 34 slides

Evolution of Fabric Structure and Design in Indian Textile Industry

The power loom sector is pivotal to the Indian Textile Industry, employing millions and contributing significantly to the economy. The development of looms like the Dobby Loom has revolutionized fabric weaving, enabling intricate designs like the Mock Leno weave. Through advanced techniques, such as

0 views • 18 slides

Dobby and the Doubling Machine Adventure

Dobby, a friendly alien, explores a spaceship with his best friend Kenny. They encounter a mysterious Doubling Machine that can double various fruits. Join Dobby as he doubles apples, pears, bananas, and more with the help of the machine. Discover the fun and surprises in this colorful and engaging

0 views • 14 slides

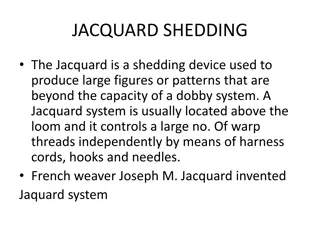

Understanding Jacquard Shedding in Weaving Technology

Jacquard shedding in weaving involves a system that controls a large number of warp threads independently, allowing for intricate and detailed patterns that go beyond what a dobby system can achieve. Different types of Jacquard shedding systems exist, each with specific characteristics and working p

1 views • 8 slides

Understanding Dobby Shedding in Fabric Manufacturing

Dobby shedding is a crucial technique in fabric manufacturing, allowing for the creation of intricate designs and patterns. This process involves the use of a shedding device attached to a loom to produce small motifs. Dobby systems offer a wide range of design possibilities, including Twill, Satin,

5 views • 18 slides

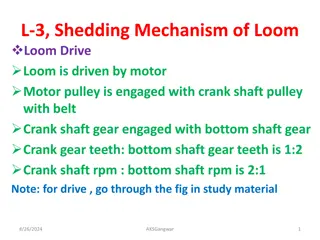

Understanding Shedding Mechanism in Loom Drive and Types of Sheds

Shedding in the weaving process involves the division of a single layer of warp sheet into two layers using heald shafts. The loom drive is powered by a motor, and the shedding mechanism includes tappet, dobby, and Jacquard systems. Different types of sheds include open sheds, semi-open sheds, and c

0 views • 27 slides

Progress on Loom Development & CFC Projects in Textile Engineering Industry

TEI focuses on advancing loom development and establishing a Common Facility Center in collaboration with various organizations to enhance technological capabilities and promote industry growth. The Loom Development Project involves a consortium of members pooling funds, seeking approval, and conduc

0 views • 5 slides

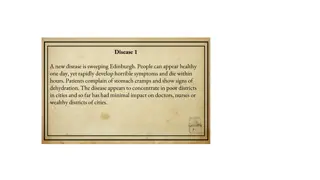

Mysterious Diseases in Edinburgh

A series of mysterious diseases are plaguing the city of Edinburgh, each with unique and deadly symptoms. From rapid onset and dehydration to rashes, lumps, and pustules, these illnesses are causing widespread panic. The origin of these diseases remains unknown, and different districts of the city a

0 views • 4 slides

Investment in Theatre Buildings Survey Findings - June 2024

Survey findings in June 2024 reveal that 1 in 5 SOLT & UK Theatre venues need over 5 million in investment to sustain operations. Without this support, closure and safety concerns loom. Access to necessary funds would improve sustainability, programming diversity, job creation, and community outreac

0 views • 10 slides

Comprehensive Guide to Textile Industry Practices

Explore various aspects of textile manufacturing, from yarn selection to loom operation and maintenance. Learn about design considerations, weaving techniques, fabric finishing, and workspace organization. Follow step-by-step procedures for efficient production and quality control in the textile ind

0 views • 12 slides