Understanding Viscoelasticity and Relaxation in Amorphous Materials

Dive into the world of viscoelasticity and relaxation in amorphous materials, exploring concepts like complex shear modulus, Maxwell element, and phenomenological models. Discover the intriguing nature of glass, its transition between solid and viscous states, and the various theories surrounding it. Delve into after-class reading resources focusing on inorganic glasses and glass science, shedding light on unanswered questions in the field. Learn about the elastic and viscous responses of materials, the role of shear/storage modulus, and various relaxation mechanisms in viscoelastic solids.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

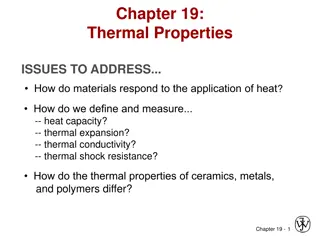

MIT 3.071 Amorphous Materials 7: Viscoelasticity and Relaxation Juejun (JJ) Hu hujuejun@mit.edu 1

After-class reading list Fundamentals of Inorganic Glasses Ch. 8, Ch. 13, Appendix A Introduction to Glass Science and Technology Ch. 9 (does not cover relaxation) 2

The Nature of Glass Remains Anything but Clear What don t we know? Science309, 83 (2005). 3

There are more theories of the glass transition than there are theorists who propose them. David Weitz, Harvard University

Is glass a solid or a viscous liquid? V Supercooled liquid Solid Elasticity instantaneous, transient = = Liquid Viscosity time-dependent, permanent Glass E x x xy t = xy G xy xy : viscosity (unit: Pa s or Poise) E : Young s modulus G : shear modulus Tm T 5

Viscoelasticity: complex shear modulus Consider a sinusoidally varying shear strain ( ) xy i t = 0exp ( ) = = 0exp i t Elastic response: G G xy xy Viscous response: = ( ) xy t = i t = 0exp i i xy xy Loss modulus In a general viscoelastic solid: ( ) xy G i = + = * = + = + * G ' " G G i G i G xy xy G* : complex shear modulus Shear/storage modulus 6

Phenomenological models of viscoelastic materials Elasticity: Hookean spring = G xy xy Viscosity: Newtonian dashpot xy t = xy Models assume linear material response or infinitesimal stress Each dashpot element corresponds to a relaxation mechanism 7

The Maxwell element = = G V t E E V Serial connection of a Hookean spring and a Newtonian dashpot = = = + Total stress: E V Total strain: E V 8

The Maxwell element = = G V t E E V ( ) = = = consta nt 0 t Constant stress (creep): E V = + = + t E V G ( ) = + = consta nt 0 t Constant strain (stress relaxation): E V t t Relaxation time = = = 1 exp exp V E G 9

The Maxwell element = = G V t E E V Oscillatory strain: = + ( ) = 0exp i t E V + 2 2 = ' G G 2 2 1 + = " G G 2 2 1 10

The Voigt-Kelvin element Parallel connection of a Hookean spring and a Newtonian dashpot = = G E E = + Total stress: E V = Total strain: E V = G Constant strain: Constant stress: = V t t V = 1 exp G ( ) = 0exp i t Oscillatory strain: = = ' " G G G G 11

Generalized Maxwell model For each Maxwell component: = = + ... i = = = 1 G 1 G + i i t t i i 1 G = i i 1 1 i t G G i i i = ... G 1 2 2 Total stress: = + + + + ... ... G 1 i 12

Generalized Maxwell model Stress relaxation: consta = ( ) nt t 0 G Prony series: = = = + + + + ... ... G G 1 i 1 1 t + exp G G i G 0 i i 2 2 ( ) + exp G t G R In real solids, a multitude of microscopic relaxation processes give rise to dispersion of relaxation time (stretched exponential) 13

Elastic, viscoelastic, and viscous responses Stress Stress Stress t t t Elastic strain Viscoelastic strain Viscous strain t t t 14

Viscoelastic materials Mozzarella cheese Human skin Turbine blades Volcanic lava Naval ship propellers Memory foams 15

Boltzmann superposition principle In the linear viscoelastic regime, the stress (strain) responses to successive strain (stress) stimuli are additive Strain Strain Strain 2 1 1 t t t 2 t2 t1 Stress Stress Stress t t t t2 t1 ( ) ( ) = = + = G t t G t t 1 2 2 2 2 1 1 1 16

Boltzmann superposition principle In the linear viscoelastic regime, the stress (strain) responses to successive strain (stress) stimuli are additive = Strain Viscoelastic response is history-dependent Relaxation function dictates time-domain response i i td dt = ' dt t ' 0 ( ) Stress = = G t t i i i i i d d dt t t ( ) = = ' ' i dt G t t d t t ' d t 0 0 17

V Structural relaxation in glass Supercooled liquid Glass transition Glassy state T Viscoelastic regime ~ re Viscous regime Elastic regime t t t obs re obs re obs Glass structure and properties are history- dependent Structural changes are instantaneous: equilibrium state can be quickly reached All mechanical and thermal effects only affect atomic vibrations Ergodicity breakdown 18

V Structural relaxation in glass Supercooled liquid Glass transition Glassy state T Viscoelastic regime Viscous regime Elastic regime DN DN ~1 DN 1 1 = DN t Deborah number (DN): re obs the mountains flowed before the Lord Prophetess Deborah (Judges 5:5) 19

Comparing stress relaxation and structural relaxation V T Equilibrium state Zero stress state Driving force Residual stress Relaxation kinetics Exponential decay with a single relaxation time Relaxation rate scales with driving force Equilibrium state Supercooled liquid state Driving force Free volume Relaxation kinetics Exponential decay with a single relaxation time Relaxation rate scales with driving force = V V V f e 20

Free volume model of relaxation (first order kinetic model) Relaxation kinetics at constant temperature ( ) ( 0 exp f V t V t V ( ) ) = V = t V t = V f e ( ) t re V f f = T re Temperature dependence of relaxation V V E E V t f f = = = exp exp a a 0 re k T t k T 0 B B 21

Model predicted relaxation kinetics Cooling rate: 10 C/s Varying reheating rate Slope: volume CTE of supercooled liquid 10 C/s 1 C/s 0.1 C/s 22

Model predicted relaxation kinetics Varying cooling rate Reheating rate: 1 C/s 100 C/s Fictive temperature and glass structure are functions of cooling rate 10 C/s 1 C/s 23

Tools Fictive temperature theory Fictive temperature Tf : the temperature on the supercooled liquid curve at which the glass would find itself in equilibrium with the supercooled liquid state if brought suddenly to it V, H Supercooled liquid Increasing cooling rate With increasing cooling rate: 3 2 1 Tf1 < Tf2 < Tf3 A glass state is fully described by thermodynamic parameters (T, P) and Tf Glass properties are functions of temperature and Tf (structure) Tf1 Tf2Tf3 ( H T T T ) ( ) = = , , V V T T H f f 24

Tools Fictive temperature theory Glass property change in the glass transition range consists of two components V, H Supercooled liquid Increasing cooling rate Temperature-dependent property evolution without modifying glass structure Volume: ( V Enthalpy: ( H ) 3 2 1 = = T , V g C T f ) T , P g T f Property change due to relaxation (Tf change) Volume: ( V Enthalpy: ( H Tf1 Tf2Tf3 ( H T T T ) ) = ( ) T = = , , V V T T H , , f V e V g T f f ) = T C C , , f P e P g T 25

Tools Fictive temperature theory Glass property change in the glass transition range consists of two components ( ) , f dV T T V dT T V, H Supercooled liquid Increasing cooling rate dT dT V T f = + T f T f 3 2 1 dT dt dT dt ( ) f = + , , , V g V e V g ( dT ) , dH T T dT dT H T H T f f = + Tf1 Tf2Tf3 ( H T T T ) T f T f ( ) dT dt dT dt ( ) = = , , V V T T H f = + C C C f f , , , P g P e P g 26

Predicting glass structure evolution due to relaxation: Tool s equation Consider a glass sample with Fictive temperature Tf P T P T ( ) g = e P P T T g e f P (V, H, S, etc.) Take time derivative: Supercooled liquid dP dt P T dT dt P T g g f = e Assume first-order relaxation: dP dt P P Glass g g e = Pg - Pe re dT dt T T Tf - T f f = Tool s equation T Tf re 27

Tools Fictive temperature theory = Line : D'M T T f dT dt T T f f ) = Tool s equation re ( dT , dH T T dT dT H T H T f f = + T f T f dT dt dT dt ( ) f = + C C C , , , P g P e P g J. Am. Ceram. Soc.29, 240 (1946) 28

Difficulties with Tools Tf theory Ritland experiment: two groups of glass samples of identical composition were heat treated to obtain the same refractive index via two different routes Group A: kept at 530 C for 24 h Group B: cooled at 16 C/h through the glass transition range Both groups were then placed in a furnace standing at 530 C and their refractive indices were measured as a function of heat treatment time Glass structure cannot be fully characterized by the single parameter Tf J. Am. Ceram. Soc.39, 403 (1956). 29

Explaining the Ritland experiment n ( ) t exp ,1 re t ( ) t exp ,2 re Structural relaxation in glass involves multiple structural entities and is characterized by a multitude of relaxation time scales Tool-Narayanaswamy-Moynihan (TNM) model 30

What is relaxation? Finally done with my 3.071 project ! 31

Relaxation: return of a perturbed system into equilibrium Examples Stress and strain relaxation in viscoelastic solids Free volume relaxation in glasses near Tg Glass structural relaxation (Tf change) Time-dependent, occurs even after stimulus is removed DN = t Debroah Number: re obs DN >> 1: negligible relaxation due to sluggish kinetics DN << 1: system always in equilibrium DN ~ 1: system behavior dominated by relaxation 32

Driving force P P P t Modeling relaxation Relaxation rate = e re Maxwellian relaxation models t ( ) ( P t ) = + exp P P P 0 e e re t ( ) ( P t ) = + exp P P P 0 e e re Boltzmann superposition principle in linear systems d dt ( ) ' t ( ) ' t = S = R IRF t t G t t d dt d dt t t ( ) t ( ) ( ) t = = = ' ' dt G t t dt ' ' ' R IRF t t S dt ' 0 0 0 33

Glass transition as a relaxation phenomenon: models Free volume relaxation theory V V t E f = exp a k T 0 B Tool s Fictive temperature theory Uses a single parameter Tf to label glass structure Tool s equation (of Tf relaxation) dT T T dt f f = re Structural relaxation in glass involves multiple structural entities and is characterized by a multitude of relaxation time scales The Ritland experiment 34