Plastic Colloquium

Explore the importance of product standards certification in ensuring safe and legal products. Learn about ISO, SANS, and SABS standards for quality assurance. Discover guidelines for eco-design management in organizations. Delve into the European Certification of Plastics Recyclers scheme and the significance of design for recycling. Uncover the impact of certification on enhancing product quality and sustainability.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Product Standards & Certification

PRODUCT STANDARDS & CERTIFICATION Civil Society Perspective Product standards: validation/authentication/definition/labelling Every organization involved in the manufacture of all types of packaging and packaging materials can show their commitment to producing a safe, functional and legal product by obtaining certification to a standard. Certification is regularly required by customers as part of their supplier approval procedures ISO, SANS, SABS and other standards are more about structural performance abilities and applications of plastics and preparation of materials Standards are not directed to recyclability

PRODUCT STANDARDS & CERTIFICATION Civil Society Perspective Guidelines to assist organisations in establishing, documenting, implementing, maintaining and continually improving their management of eco-design as part of an environmental management system (EMS)? What are the pros and cons of SANS 14006, 14020, 14024, etc.? Should these SANS be mandatory for plastic products? These are non-certifiable guidance standards, intended to assist organisations in implementing eco-design activities within an EMS primarily but not exclusively conforming to ISO

European Certification of Plastics Recyclers (EUCERTPLAST) The specific objective of this project is to develop a European wide certification scheme for post-consumer plastics recycling. This scheme will assess the good practice, the output quality and the gain in terms greenhouse gases done by the audited recycler. The intention is that the waste collectors will have a harmonised European tool to guarantee that the waste they deliver will be recycled in a sustainable manner by the recycler. The responsible recyclers will benefit from this certification which will consent an increase market for plastics secondary raw materials, a sound recycling activity and the increase recycled quantities. Moreover, this increase transparency will permit a quality guarantee to plastics converters. Consequently, this will lead to an increase use of recycled material in new products. The foreseen certification will work according to the European Standard EN 15343:2007, published in April 2008, aims to encourage an environmentally friendly recycling of plastics by standardising it. This standard is particularly focusing on the process for the traceability and assessment of conformity and recycled content of recycled plastics. Standards enforced on the Recycler not the Producer!

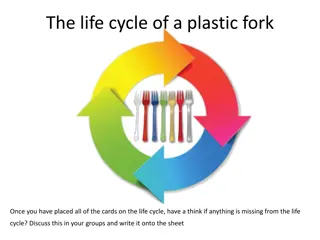

DESIGN FOR RECYCLING Recycling of plastics does not begin with collection but rather with the design of products. Recycling processes are very often hampered by inseparable polymer composites, unnecessary use of additives or combining of plastics with other materials (paper, metal, fibres) in a way that does not allow for an easy separation. The essential criterion of product design currently is its high performance. The new challenge, however, should be to incorporate the recyclability aspect and to make it a requirement on top of the other performance criteria: product safety, shelf life, marketing and branding, etc. It is important to balance those various objectives of a plastic product, without ignoring its recyclability. According to the Global Plastics Outreach Alliance definition, a product is considered recyclable if it meets the following conditions:

The product must be made with a plastic that is collected for recycling, has market value and/or is supported by a legislatively mandated program. The product must be sorted and aggregated into defined streams for recycling processes. The product can be processed and reclaimed/recycled with commercial recycling processes. The recycled plastic becomes a raw material that is used in the production of new products. PRE created RecyClass with the aim of improving the design of packaging so that it is easily recyclable into high-quality recyclates which can then be used in a new plastic product. Far too much plastic is not fit for recycling and is hence destined only for energy recovery - the last but one option in the waste hierarchy pyramid. RecyClass is a free online tool which enables the assessment of virtually any plastic package regarding its recyclability. The tool provides advice and recommendations on how to improve design in case the product scores rather poorly in the assessment. In the last steps of the evaluation, the product can be certified by an expert in order to use the RecyClass branding. By improving product design, RecyClass will help divert substantial quantities of plastics away from landfills and incineration plants, and ultimately help reach higher recycling targets while saving the natural resources.

'TRAFFIC LIGHT' LABELLING eco-labelling , involving a new combined colour and number system