Operational Improvements for Aluminum Smelter in Trondheim

The aluminum smelter in Trondheim is facing challenges with high CO2 emissions and operational inefficiencies. To avoid hefty penalties and improve practices, recommendations include reducing amperage, enforcing operating procedures, meeting specifications for alumina and coke purchasing, renovating anode furnaces, and upgrading anode effect kill logic. New operating targets focus on slight amperage decrease, improved current efficiency, and reduced anode consumption. These measures aim to enhance sustainability and productivity in the smelting process.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Environment Group 6 Discussion 37thInternational Course on Process Metallurgy of Aluminium 20 June, 2019 1

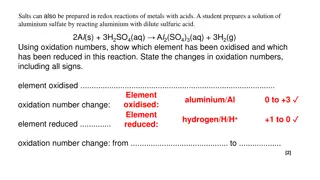

Current Situation Aluminum smelter on Trondheim: 271 000 tonnes of CO2-e per year Must reduced below 200 000 tonnes CO2-e per year to avoid 3 Million USD penalty per year Situation of the potline: - 200 AP- 18 pots operating at 235 kA from 220 kA - CE: 92.0 % from 95.5 % - High temperatures, squeezed ACD, spikes and burn offs - Net carbon: 0.47 t/t Al from 0.42 t/t Al - Annual production @ 235 kA = 126 971 tonnes/ year Anode baking furnace: - Very poor conditions 2

Current Situation - Cont. Purchasing: low density coke Out of specifications Alumina: below 45 m : more than 30 % (spec 8 %) below 20 m : more than 15 % (spec 1%) Anode effect kill logic: Long waiting time before squelching (45 seconds) 3

Objective Reduce CO2-e emission to < 200 000 t CO2-e/y to avoid paying the tax Restore operational practice and good operation 4

Recommendations Reduce amperage only to 230 kA To ease the a-c distance by slightly increasing target pot voltage with a reasonable increase of current efficiency to 95% ( not 95.5% achieved at 220 kA) Review & enforce operating procedures: Permanently maintained bath level height by measuring before and after metal tapping and correct as required (Tap or pour bath) Maintain correct anode cover thickness with 2 redressing per week and carry out systematic anode cover thickness audit Systematic skimming of the bath from carbon dust this requires to hire additional 16 operators (4 workers/shift and 2/ potroom) 5

Recommendations Cont. Meet with Purchasing Department Stress on the following: 1. make sure to buy alumina according to the acceptable specifications ( 45 < 8 % and 20 < 1%) 2. buy coke according to specification Renovate anode furnaces - (a 2 year project) Upgrade and modify Anode effect kill logic - ( a 2 months project) 1. immediate squelching 2. have a target of 20 seconds to kill anode effect Finally, look at creep increase back to 235 kA after the situation has been restored at 230 kA. 6

New Recommended Realistic Operating Targets Amperage: slight decrease to 230 kA Current efficiency: 95 % Anode consumption: 0.415 t/tAl Anode Effect Frequency (AEF): 0.2 AEF min. 0.067 Anode Effect Duration (AED): 20 seconds 7

Expected Annual Production and Emissions Annual production: 128 322 tons (improvement from 126 971 due to improve CE 95 % instead of 92 % in spite of lower amperage) Total emissions: From anodes: CO2-e: 190 750 t (instead of 213 500) From Anode Effects: CO2-e 5141 t (instead of 56 947) Total: 195 891 t CO2 8

Calculations CO2 from Anode A B C E F D (100% D-C) (A*B*E)*3.67 Potline, 200 Cells Al Net Anode Consume (t C/t Al) 0.415 Sulfur (%) Ash (%) Carbon Content CO2 (tonne/yr) Emissions (tonnes CO2) 230 kA & 95% CE 128 322 2.0 0.4 0.976 190 750 9

Calculations CO2-e from Anode Effects A B C E D (A*B*C) (AEF*Minutes) (D*6.5) Potline, 200 Cells Al CF4 Slope Factor 0.092 AE Total CF4 (Kg CF4 ) CO2-e (tonne CO2 (Minutes) (tonne) 230 kA & 95% CE 128 322 0.067 791 5141 Total: 195 891 t CO2 10 Potline operation - M Reverdy

Thank you! 11