Understanding the Significance of Operations and Maintenance Management in Infrastructure Delivery

This informative content delves into Module 8 of the Infrastructure Delivery Management System (IDMS), focusing on Operations and Maintenance. It emphasizes the importance of efficient management processes in ensuring service delivery, asset functionality, and overall lifecycle performance. Highlighting the key points and differences between projects and daily operational activities, it underscores the essential role of Operations and Maintenance in sustaining infrastructure assets.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

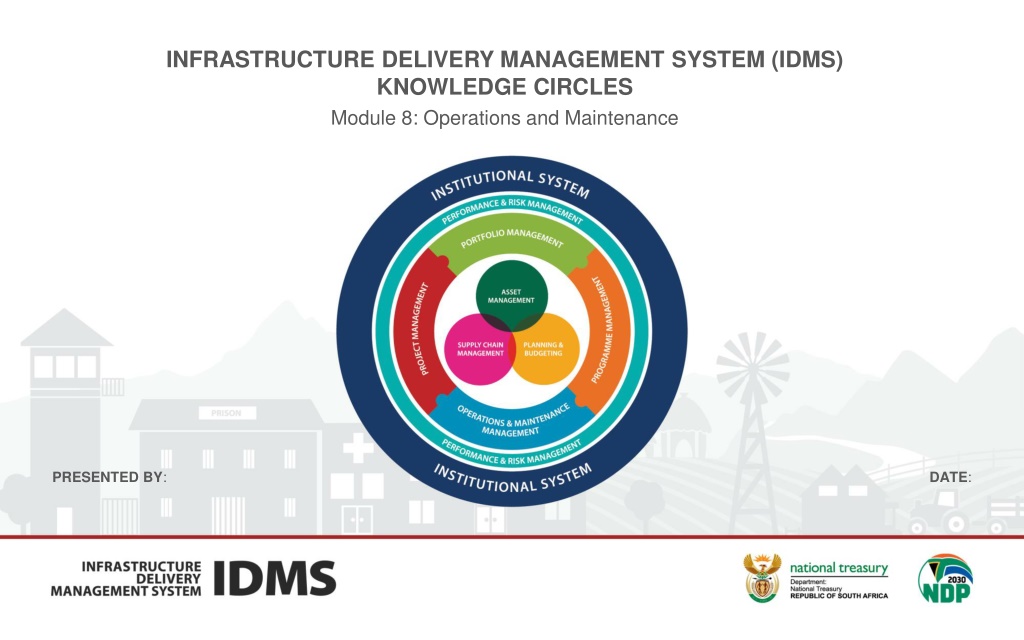

INFRASTRUCTURE DELIVERY MANAGEMENT SYSTEM (IDMS) KNOWLEDGE CIRCLES Module 8: Operations and Maintenance PRESENTED BY: DATE: 1

MODULE 8 Operations and Maintenance (Version 5.0 - 2023) 2

Module 8: Operations and Maintenance Management Module 8: Operations and Maintenance Management is one of the four delivery management processes: MODULE 6 Portfolio Management Process MODULE 7 Programme Management Process MODULE 8 Operations & Maintenance Management Process MODULE 9 Project Management Process & Project Lifecycle 3

Why is Operations and Maintenance so important? SERVICE DELIVERY Availability Utilisation Quality Safety Life long relationship = Life cycle Asset Functionality 4

1. Purpose of Module 8: Operations & Maintenance Management Process Key points: 1. To provide operations and maintenance managers with relevant guidance. MODULE 6 Portfolio Management Process MODULE 7 Programme Management Process on its own is not sufficient: MODULE 8 Operations & Maintenance Management Process 2. It is reliant on working in synergy with the other three delivery management modules of Portfolio Management, Programme Management and Project Management. MODULE 9 Project Management Process & Project Lifecycle 3. Delivery management modules are generic, scalable and applicable to all spheres and sectors of government, including state-owned enterprises. Organs of state are encouraged to adapt the processes and procedures tables contained in the delivery management modules to their policies and specific needs. 5

3. Introduction 3.1.4 Projects versus Operations & Maintenance While this module does not directly deal with project management (which is covered in Module 9), it is nonetheless useful to highlight the primary difference between implementing operations and maintenance activities or actions, and implementing a project. Where a project is: Temporary in nature, with a defined start and end; Has unique deliverables, often being delivered at the end of well-defined stages; Implemented by teams specifically formed for the purpose of carrying out the project; Concluded when specific objectives have been met, or it might be terminated without the objectives being met. Operations and maintenance are defined, respectively, as follows: Operations: The active process of utilising an asset which will consume resources such as manpower, energy, chemicals and materials. Maintenance: All actions intended to ensure that an asset performs a required function to a specific performance standard(s) over its expected useful life by keeping it in as near as practicable to its original . 6

3. Introduction 3.1 3.1.1 Applicable definitions and standards Operations The International Infrastructure Management Manual (IIMM) defines Operations as The active process of utilising an asset which will consume resources such as manpower, energy, chemicals and materials . Infrastructure Asset (IA) Operations is concerned with processes that provide instructions to Operators about how to operate the assets, within the appropriate design, maintenance and operational parameters. Asset Operations includes the development of an Asset Operations Strategy and Operations Management Plans, that outline the approach, activities and resources involved in managing and implementing operations. 8

3. Introduction 3.1.2 Maintenance The National Immovable Asset Maintenance Management (NIAMM) Standard defines Maintenance as All actions intended to ensure that an asset performs a required function to a specific performance standard(s) over its expected useful life by keeping it in as near as practicableto its original condition, including regular recurring activities to keep the asset operating, but specifically excluding renewal . The NIAMM Standard uses the term asset care to link maintenance with the periodic renewal of infrastructure assets, and defines renewal as: Expenditure on an existing asset which returns the service potential of the asset or expected useful life of the asset to that which it had originally. Renewal can include works to replace existing assets or facilities, with assets or facilities of equivalent capacity or performance capability. It is important to differentiate renewal from maintenance, as expenditure on renewals is funded through the entity scapital budget, and not the operating budget, as is the case for maintenance. 9

3. Introduction 3.3.6 Plan-Do-Check-Act (PDCA) cycle The words, Plan , Do , Check and Act appear along the top of the IDM Process Diagram to depict the application of a continuous improvement approach to the entire IDM system within an organ of state. A PDCA cycle used with the process approach is a four-step iterative process used to analyse information and continually improve decision making processes to achieve intended results, and should not be viewed as a lifecycle process. The PDCA cycle can be briefly described as follows: Plan: establish the objectives of the system and its processes, and the resources needed to deliver results in accordance with customers requirements and the organization s policies; Do: implement what was planned; Check:monitor and (where applicable) measure processes and the resulting products and services against policies, objectives and requirements and report the results; Act: take actions to improve performance, as necessary. 10

Evidence-based decision making Integrated IDM Process Roadmap 12

4. RASCI Table, Process Maps and Procedures Tables 4.1 4.1.1 4.1.2 4.1.3 4.1.4 Planning Phase Verify IA Register Operations Management Planning Sub-phase Maintenance Management Planning Sub-phase Renewals Management Planning Sub-phase 13

4. RASCI Table, Process Maps and Procedures Tables 4.1.1 Verify IA Register The Verify IA Register Sub-phase is shown in context with the other Operations and Maintenance Management phases and sub-phases in figure C.1.1below. 14

Functional Performance Index Operating Performance Index Sustainability Index Determining Functional Performance Re-measure & Update Asset Condition Performance Register 1 Optimal 2 Minimum 3 Outside Optimal A A1 A2 A3 Group A: Immovable assets that meet the User s requirements as near as practicableto its original condition. These assets only require ongoing preventative maintenance. Minimum B B1 B2 B3 Outside C C1 C2 C3 A1 or B1 or A2 or B2 Preventative Maintenance Preventative Maintenance Group A Group B: Immovable assets that are suitable to User s requirements, but require technical condition assessment, as the asset performance does not meet minimum functional requirements of the facility. These assets are likely to require renewals. Technical Assessment- condition-based maintenance Rehabilitate or Refurbish Group B A3 or B3 Feasibility Study to determine Salvageability Group C: Immovable assets that have been identified as unsuitable to the current User s requirements. These assets could potentially be due for disposal. Deploy Asset to new User C1 or C2 or C3 Group C Dispose the Asset 16

Funding Zero-based Planning and Budgeting Meaning of zero-based covered in next 2 slides. IDMSBOK. What is needed to operate effectively and efficiently: Apply one s mind CAF (consider all factors). Not adding % to existing. Not copying and pasting. 6M s. 17

Zero-Based Budgeting Features (Source: https://finlawportal.com/zero-based-budgeting-how-to-implement-it/. Accessed 17/03/2022). The same features apply to Zero Based Operations and Maintenance Planning. Features of Zero-Based Budgeting Without justification, the budget allowance is zero Avoids blanket increases or decreases to a specific period s budget 01 02 03 04 05 Focus is not on how much a unit will spend but on why it needs to spend What each unit can offer for a specified cost is seen Objectives of individuals units are linked to corporate targets 18

6Ms for Planning and Budgeting 1. Material Operating. Maintenance. 2. Machines Equipment. Tools. 3. Men People Salaries/rates/fees. Training and coaching. Safety. Market Serving the public clean/hygiene, safe, available, secure (security). 4. 5. Management Roles and responsibilities (RASCI), Performance Indicators and KPIs, supervision, monitoring and control, administration, procurement. 6. Money Maintenance ringfenced in Operations budget, Equitable share, Grant funding etc. 19

4. RASCI Table, Process Maps and Procedures Tables 4.2 4.2.1 4.2.2 4.2.3 4.2.4 Mobilisation Phase (by Client) Review of O&M Management Policy and Plans (by client) OMP Approval Sub-phase (by Client) MMP Approval Sub-phase (by Client) RMP Approval Sub-phase (by Client) 20

No. Sub-phase / Activity Name and Definition Description Inputs Outputs C.2.1 Review of O&M Management System. C.2.1.1 Review the Operations and Maintenance Implementation Strategy. Step 1: Assess available options for implementation of the OMP and MMP. Existing Operations and Maintenance Implementation Strategy. Updated Operations and Maintenance Implementation Strategy. The objective of the Review the Operations and Maintenance Implementation Strategy activity is to review the available options for implementation of the OMP and MMP. C.2.1.2 Develop/review documented procedures for managing facility or system shutdown events. Step 1: Review existing procedures for managing facility or system shutdown events. Existing procedures for managing facility or system shutdown events. Updated procedures for managing facility or system shutdown events. See Sections 6.2.1 & 6.2.2 of the NIAMM Standard for more information on procedures for managing shutdown events. C.2.1.3 Design/review of Preventative Operations and Maintenance Management System. Step 1: Review existing preventative Operations and Maintenance Management System. Existing Preventative Operations and Maintenance Management System. Updated Preventative Operations and Maintenance Management System. See Sections 6.1.1 & 6.1.2 of the NIAMM Standard for information on designing a Maintenance Management System. 23

No. Sub-phase / Activity Name and Definition Description Inputs Outputs C.2.1.4 Document/review procedures for managing Corrective Maintenance incidents and/or emergencies. Step 1: Review existing procedures for managing corrective maintenance incidents and/or emergencies. Existing procedures for managing Corrective Maintenance incidents and/or emergencies. Updated procedures for managing Corrective Maintenance incidents and/or emergencies. See sections 7.1.2, 7.1.3 & 7.2.2 of the NIAMM Standard for more information on procedures for incidents and/or emergencies. C.2.1.5 Allocate roles and responsibilities for maintenance management and incident management Step 1: Review existing roles and responsibilities. Existing Responsibility Assignment Matrix. Updated Responsibility Assignment Matrix. See Section 4 of NIAMM Planning Guideline and Section 7.1.5 of the NIAMM Standard for more information on the importance of allocating roles and responsibilities. See Section 12.1.1 of the NIAMM Standard for guidelines on outsourcing of maintenance and renewal activities. C.2.1.6 Review logistical support. Step 1: Review existing Logistical Support Plan. Existing Logistical Support Plan. Updated Logistical Support Plan. The objective of the Review logistical support activity is to consider the options for the acquisition and distribution of the materials and equipment required for implementing the OMP and MMP. 24

All actions intended to ensure that an asset performs a required function to a specific performance standard(s) over its expected useful life by keeping it in as near as practicableto its original condition, including regular recurring activities to keep the asset operating, but specifically excluding renewal . Operations & Maintenance Preventative Maintenance Corrective Maintenance Operation & Maintenance Types (Actions to Slow Deterioration or failure) (Actions to Respond to Breakdown or failures) Planned Repair (designed modifications) Emergency Repair (immediate modifications) Maintenance Approach Interval-based Condition-based Priority Repair(s) based on incident reporting and fault logging procedures Immediate Response to a situation of emergency Scheduled Monitoring Inspections Testing Operations Approach Servicing and maintenance actions Frequency estimated based on analysis or experience etc., subject to inspections, testing and monitoring. Servicing and maintenance actions Repairs Frequencyestimatedbasedon: Prescribed frequency e.g. based on suppliers manuals or experience. Condition; and Criticality of asset(s) Operational & Maintenance Actions Operations & Maintenance: Programmes of O&M and Projects 26

4. RASCI Table, Process Maps and Procedures Tables 4.3 4.3.1 4.3.2 4.3.3 Implementing and Managing Phase (by Client) Implementation of O&M Management Policy and Plans Sub-phase (by Client) Record Information Sub-phase (by Client) Reporting Sub-phase (by Client) 27

4.3 Implementing and Managing Phase 4.3.2 Record Information Sub-phase 31

4.3 Implementing and Managing Phase 4.3.3 Reporting Sub-phase 32

4.4 4.4.1 4.4.2 4.4.3 Review Phase (by Client) Collate Information Sub-phase (by Client) Conduct Maturity Assessment Sub-phase (by Client) Conduct Management Review Sub-phase (by Client) 33

No. Sub-phase / Activity Name and Definition Description Inputs Outputs Collate Information. C.4.1 Assess actual versus planned O&M performance. The Assess actual versus planned O&M performance process is to assess actual performance against the planned performance, based on analyses of the O&M progress and performance reports. Step 1: Analyse O&M progress and performance reports. Identify deviations from O&M performance targets. Existing O&M Performance Report. O&M Performance targets. O&M Progress and performance reports. Updated O&M Performance Report. C.4.1.1 Step 2: Identify the O&M performance issues and risks. The Identify O&M performance issues and risks process is to list the reported performance issues and risks. Step 1: Assess the reported O&M performance issues and risks. Update the O&M Issue Log and Risks Register. Existing O&M Issue Log and Risks Register. Actual versus planned O&M Performance Report. Updated O&M Issue Log and Risks Register. C.4.1.2 Step 2: Assess O&M objectives and KPIs. The Assess O&M objectives and KPIs process is to propose changes to the stated O&M Objectives and/or the KPIs, in line with the identified performance issues and risks. Step 1: Analyse the updated O&M Issue Log and Risks Register. Assess validity of O&M objectives and KPIs. Adjust the stated O&M Objectives and/or the KPIs, in alignment with the identified performance issues and risks. Existing O&M Objectives and KPIs. Updated O&M Issue Log and Risks Register. Updated O&M Objectives and/or KPIs. C.4.1.3 Step 2: Step 3: 35

4.5 4.5.1 Improvement Phase (by Client) Develop Continuous Improvement Plan Sub-phase (by Client) 38

THANK YOU! 40