Understanding Meat Processing: From Ancient Techniques to Modern Innovations

Meat processing involves various methods such as curing, smoking, canning, cooking, and more to alter fresh meat for consumption. The practice has evolved from ancient civilizations like the Egyptians and Romans to modern times, focusing on improving shelf life, flavor, and nutritional value of meat products. Advantages include enhancing taste, value addition, and utilization of low-value cuts effectively. The future of meat processing lies in sanitation, quality control, and diverse product offerings.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

LPT 602: MEAT PROCESSING , PACKAGING, QUALITY CONTROL AND MARKETING Unit I: Meat Processing: Introduction By: Dr. R. K. Jaiswal Asstt. Prof.-cum-Jr. Scientist Dept. of LPT Bihar Veterinary College Bihar Animal Sciences University Patna-800014 (Bihar)

Meat Animal tissues which are suitable for use as food. More component originating from live animals precisely edible postmortem

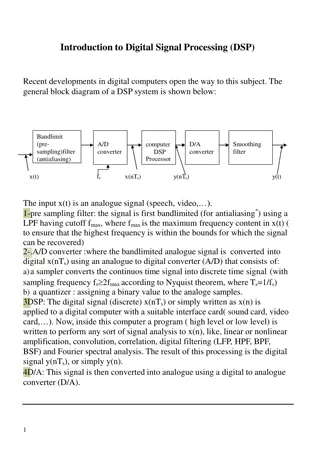

What meat processing means? All process utilized in altering fresh meat except for simple grinding, cutting and mixing Includes curing, smoking, canning, cooking, freezing, dehydration, production of intermediate moisture products and the use of certain additives such as chemicals and enzymes Excludes cutting, grinding and packaging of fresh meat in retail stores and in homes

Meat Processing Origin before the dawn of civilization Egyptian- preservation of meat products by salting and sun drying. Romans- 1st to use ice and snow as a means of preserving foods. Modern food processing- Canning- Nicholas Appert. Newer methods of meat preservation- Chemical additives, development of IMF, freeze dehydration, Enzymes treatments, Irradiation. Jerky a thin dried strips of meat- American Indians. Pemmican, mixture of dry and semidry meat pounded with dried fruits and vegetables covered with melted fat. High energy and lightweight foods. Emphasis over nutritional adequacy and balanced diets Future of Meat Processing- Carefully controlled sanitation and quality control practices, emphasis on growth, expansion, diversity and efficiency processing plant, production of mixed foods.

PURPOSE OF MEAT PROCESSING Changing from time to time Improve shelf life, flavour and nutritive value Modify or upgrade the less desirable meat cuts to desirable products Provide convenience and variety products

ADVANTAGES OF MEAT PROCESSING Addition of different ingredients to meat improves taste and flavour. Specific processing conditions and ingredients improve shelf life. Processed products are convenient to handle and eat. Processing improves nutritive value. Products of specific requirements can be prepared e.g. for children, old age or fat people. Processing add value to meat.

ADVANTAGES OF MEAT PROCESSING Low value meat cuts can be better utilized in the processed products. Edible meat byproducts can be effectively utilized in the processed products. Processing improves demand and marketability of meat. Meat protein can be provided to consumers at affordable price. Processing industry creates/provides employment.

Principles of Product Development PRIMARY FACTORS IN MEAT PROCESSING Moisture Amount of natural moisture (water) of meat and added water retained - maximum Very important for yield and quality of the product. Fat Amount of natural and added fat retained maximum. Cohesion Able to retain its physical integrity after processing. Connective tissue Conversion of tough connective tissue to more palatable form.

Principles of Product Development Classifications of Meat products Chunk/particle size Degree of comminution Processing type Chunk/particle size Whole muscle - chunk size > 2-3 cm3 e.g. ham. Comminuted chunk size <2-3 cm3 e.g. reformed hams, ground meat patties. Emulsion fine, pasty, homogenous mixture e.g. sausages, patties

Principles of Product Development Degree of comminution None e.g. ham, bacon Some e.g. reformed ham, restructured products Coarse e.g. meat balls, ground meat patties Fine e.g. sausages Processing type Emulsion type Restructured Fermented Enrobed Intermediate moisture products Cured Smoked Canned