Factors Affecting Combing Fibre Length & Uniformity in Textile Industry

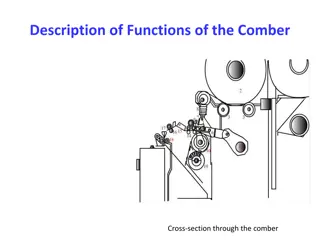

Play a critical role in deciding the combing performance. Factors include short fibre content, fibre stiffness, moisture content, fiber fineness, and foreign material. Material preparation such as fiber parallelization, sheet thickness, and evenness is crucial. Machine conditions, speeds, operation, and settings also impact combing performance. Machine components and settings influence factors like feed amount per cycle, leading to improvements in yarn quality and production efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Factors Affecting Combing Fibre Length & its uniformity: Play critical role in deciding the combing performance. If the fibre has high short fibre content, then the improvement in the yarn quality becomes significant only on removal of high amount of noil. Fibre stiffness: If the fibre stiffness is high, there is good chance of fibre breakage during the combing operation Moisture content: High moisture content is the fibres make the combing operation difficult since the fibres tend to cling to each other. Fiber fineness: Speeds and settings will be influenced by the micronaire value of the cotton being processed Foreign material associated with the fibers: If larger trash particles and metallic particles are still left in the feed lap, they can cause damage to the combing needles

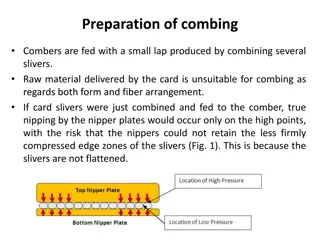

Material preparation Fiber parallelization: orientation and parallelization of fibres as they are feed to the combing head is a very critical parameter which decides the combing performance. Sheet thickness: The combing needles should be able to penetrate into the thickness of the lap. If the lap is too thick, the fibres present at the bottom of the lap will not get combed properly. This will also put too much stress on the combing needles. If the lap is too thin, then the production rate will suffer. Sheet evenness: If sheet is not even across the width, then the lap is not going to be held tightly at places across the width, which will result in pulling out of the fibres in lumps and good fibres may end up in going with the noil. Orientation of the hooks: Combing operation removes the leading hooks present in the feed lap preferentially.

Factors associated with the Machine Condition of combs: The condition of the combs like the sharpness of the needles, arrangement of the needles and the density of the needles play important role in deciding combing performance. Speeds: one cycle of combing comprising feeding, combing, detaching and top comb operation are completed. Increase in speeds became possible because of the improvement in machinery manufacturing technology, more accurately manufactured improved designs and better electronic sensors and controls. Operation of combs: The timing of operations of all combing elements is a crucial factor. The timing of comb and the depth of penetration of the combs into the lap need to be accurately set for best possible combing. Type of sliver forming element: Drafting arrangement: The combing process introduces an additional irregularity known as piecing irregularity. Hence, all the combing machines are fitted with a roller drafting system. components with

Settings Accuracy of settings is key element in good combing performance at high speeds. Feed settings like the forward/reverse feed modes, feed length and the timing of feed Detachment setting Point density of comb circular comb clothing (angles of teeth, density of teeth, etc) piecing Depth of Penetration Piecing draft and draft settings

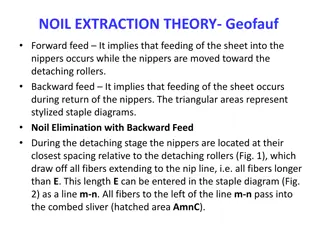

Influence of Machine Components and Settings on Combing The Feed Amount Moved per Cyclle: The amount of feed material has noticeable influence on A) Noil %, b) Quality of combing c0 production rate A high feed increases production but deterioration in quality. This correlates with fibre length Typical values for the feed amount per cycle. A, feed amount per cycle in mm; B, corresponding staple length of cotton

Type of Feed Forward feed used to be chosen for higher production rates mainly for upgrading with noil percentages of up to 12% (max. 14%). When higher demands were made on quality, backward feed had to be used with noil percentages in the range of 12 - 25%. Forward feed is mostly used over all staple ranges for achieving noil levels from 8 to 18%. One main reason is the better self cleaning effect during detaching and top combing action by generating higher retaining forces. Fiber rear ends and the hooks are more extended. Disturbing impurities (husk particles, dust and trash, leaf, fiber neps and seed coat fragments) and short (floating) fibers are hold back by the top comb during detaching and are combed out by the next circular combing cycle.

Detachment Setting This refers to the distance between the clamping line of the nippers and the nip line of the detaching rollers when these parts are at their closest spacing. The detachment setting provides the chief means for influencing the level of noil elimination. Wide detachment setting results in a high level of noil elimination; a closer setting is associated with a lower noil level. Spinning mills must find the optimal setting for their own conditions. If the detachment setting is increased, starting from a certain optimum, there will be hardly any improvement in quality except in relation to imperfections (Fig. 12). The detachment setting normally lies in the range of 15 - 25 mm. If the noil percentage varies for no reason while the machine settings (including the detachment setting) are kept constant, the cause lies not in the machine but in the raw material.

The Number of Points on the Combs Comb segments on older machines had a clothing of needles. Both the point density and the fineness of the needles were adapted to the raw material. Top combs are still clothed in this way or are equipped with teeth. Clothing of circular combs has changed in recent decades. Nowadays saw-tooth clothing is used in circular combs. In comparison with needles, the new type of clothing is more robust, needs less maintenance and it is more universally applicable. Since the combs are introduced to perform the main work of the machine i.e combing, their influence on quality is much more important. Needles on the top comb have a flattened cross-section and are formed with a bend. Usually they are used with a point density in the range of 23 - 32 needles per centimeter. Fewer needles are used when higher production is needed together with lower waste elimination. When more needles are employed, amount of noil will be high.

The Depth of Penetration of the Top Comb The depth of penetration of the top comb inside the lap has a major influence on the amount of noil extraction.. Lowering of the top comb by about 0.5 mm is followed by an increase in noil of about 2%. The main improvement due to this procedure has to be seen in the elimination of neps. Always, the optimum setting must be established, since excessively deep penetration of the top comb disturbs fiber movement during piecing and result is deterioration in quality.

Piecing After combing of the fringe protruding from the nippers, the detaching rollers draw some of the combed feedstock out of the sheet. This produces a tuft with a length dependent upon the staple length, but lacking all internal coherence. By means of the piecing operation, the rollers have to lay these newly formed strips of web on top of each other so that first a coherent web and finally an endless sliver is obtained. For this purpose, the single fiber tufts are laid on top of each other in the same way as roofing tiles. Consequently, piecing is a distinct source of faults in the operation of the rectilinear comber, but it is system-related due to the discontinuous process. The sliver produced in this way has wave-like structure, i.e. it exhibits periodic thin and thick variations.

Temperature & humidity Cotton fibres are sensitive to temperature and humidity. Maintaining the right amount of temperature and humidity is essential for efficient combing operation. Excessive humidity causes the fibres to be sticky and hampers individual movement of fibres. Very high humidity makes the fibre dry leading to uncontrolled movement of fibres. The temperature has to be keep at a level so that it is comfortable to the workers. The modern combers are fitted with highly sophisticated electronic control systems which can t operate properly at high temperatures.