Comprehensive Approach to Energy Audit & M&V Empanelment for BEE Accreditation Advisory Committee

Eco Energy Solution envisions to be a customer-centric firm excelling in Energy Audit services for BEE guidelines. Their mission focuses on integrity, dynamism, and innovation towards energy conservation. The methodology involves a detailed process from initial planning to final reporting, emphasizing data verification, analysis, and recommendations for optimizing energy consumption. A strong emphasis on quality, excellence, and dependability is highlighted in their motto.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Vision, Mission & Motto Presentation for M&V Empanelment of AEA Firm for BEE Accreditation Advisory Committee By VISION VISION Eco Energy Solution aspires to be a quality driven- customer centric firm. We strive to become one of the most dedicated & technically sound Energy Audit firm to undertake PAT advisory services for MEA and M&V as per BEE guidelines. ECO ENERGY SOLUTION MISSION MISSION Integrity Dynamism We pledge to serve the Industry and Nation by developing Technical skills and continually upgrading operating practices towards saving Energy and waste minimization. Innovation VALUES Quality Excellence MOTTO MOTTO Value Excellence, Dependability & Quality Motto Saving Heat & Power ECOENERGY SOLUTION

General Approach For Energy Audit Monitoring &analysis of use of energy data Recommend ation and Cost Benefit Analysis Deciding Scope of Energy Audit Verification of data of Energy Use Energy Audit Report Action Plan Assess team deployment / auditors/ engineers with required set of instruments. Determine offsite and on site days required to complete the study. Initiate site visit. Schedule Opening meeting. Define Objectives. Request - Equipment load list. Collect historic data - energy & production. Undertake measurements and data collection as per formats / test codes. Review & analyse collected data Vs rated performance / design values. Train Plant Personnel. Deviation & gap analysis. Recommendation for optimising energy consumption / improving performance Check Guidelines, Data authenticity. Scheduling closing meeting, Submitting action plan for implementation & monitoring to sustain performance. Support for inviting offers, review technical specifications & parameters. ECOENERGY SOLUTION

Methodology For Conduct of Energy Audit Receive Formal PO / Commencement Letter, Hold Opening Meeting Review Audit Scope & Objective Address & Management Inherent Concerns and Onsite Support Address Onsite & Offsite Mandays for Completing Agreed Scope incl Report Planning Conduct General Walk-through, Prepare Initial Plan, Discuss Procedures with Key Staff Conduct Test Work, Data collection as per Formats & Test Codes Communicate throughout on Audit Progress & Potential Findings Field Work Summarize Findings, Draft Discussions, Conclusions, Review Recommendations Conduct closing meeting, Discuss Observations & Recommendations Data Compilation, Draft Report Preparation & Submission, Address Recommendations Submit Final Report With Management Response / Comments Included Reporting Follow up on Implementation Support. Extend OEM Vendor Support, if reqd. Report Recommendation / Implementation Progress. Supervise Implementation, if reqd. Follow up Monitor Actual Savings Realised Review / Compare With Recommendations & Initial Estimation M&V ECOENERGY SOLUTION

Methodology Adopted For Conduct Of Energy Audit In Electrical/Thermal - Process Specific Areas Process Details & Flow Diagram Historic Production & Energy Data Undertake Sample Test at Design Load Study Process & Energy Input Energy & Mass Balance Flows Data Collection for Sample Test Prepare Typical HMBD Analyse Deviations, if any Measuring & Metering Sample Batch / Production Thermal Energy Input Metering Steam Flows Detailed trials Selected Energy consumers Power metering Electrical Loads Recording Fuel / Logging Energy Input Parameters Benchmark / Norms Fixation Analyse Variations in SEC Analyse Use, Trend, & Benchmarking Compute Theoretical Energy Requirement Compare Theo. Vs Actual Norms Review Best Alternative Practices Review Process Specific BAT s Review Tech-Eco feasibility for implementing BAT ENCON Opportunity ECOENERGY SOLUTION

Approach Adopted In Making Recommendations Measure Onsite Operating Parameters for Time Period as per Codes Review Design Specifications Vs Actual Operating Parameters, Review Design Performance Curves, Basis of Selection Data Acquisiti on Quantify Performance & Deviations, if any, Identify ENCON Potential & Opportunity Analyse, Develop & Shortlist Options ENCON Identify Alternative Approaches Gather Information about Each Alternative Review & Shortlist Select Option Review Continuous & Standby Demand Options Analyse Impact on Production & Energy Consumption Review Site Limitation, Tech - Eco Feasibility Strategise Implementation & Formulate Implementation Plan Affix Implementation Responsibility Mitigate Project Risks, if any Implem entation Strategy Reconfirm Option, Fix M&V Methodology Define Scope, Financial & Non Fin, Benefits, Financial Analysis Present Recommendation for Approval Recom mendati on ECOENERGY SOLUTION

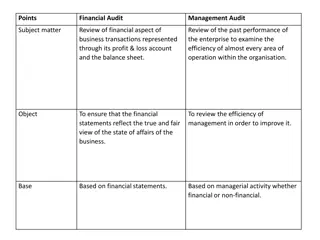

Monitoring of Action Plan / Recommendations Review recommend ations Evaluate & Assess Options Invite Offers Procure & Implement M&V 1.Review new SEC & Equipment performance 2.Review projected Vs Actual Savings 3.Quantify deviation in operating parameters, if any 1. 2. Internal Audit Management Review Training Required Continual Improvement Risk & Environmental Aspect Assessment Stat. Compliance Evaluation 1.Weigh adv & dis-adv of all options 2.Assess life cycle cost 3.Review Dynamics of process changes 4.Evaluate Standby requirements 5.Review Variability with Process 6.Finalise payback period 7.Review redundancy of existing asset 8.Mitigate Gaps if any 1.Define Scope & Tech. parameters 2.Invite offers from reputed / known experienced OEM 3.Compare tech eco values 4.Review similar installations, if any 5.Review Major /Critical Spare requirements 6.Review ease of replacement / Duplication 1.Followup with Management for Purchase requisition 2.Co-ordinate Civil works as reqd. 3.Clear Site for installation 4.Integrate Process Operation with installation 5.Plan shutdown, if reqd 6.Install I&C for proper monitoring of SEC 3. 4. 5. 6. ECOENERGY SOLUTION

Eco Energy Solution : Energy Audit Team Sr. Name 1 Qualification Total Experience B.E.-Chem. Plant Energy Audits D.E.E., D.M.E. Energy Audits M.E. Mech. 35 yr Ex GM Bhilai Steel Iron & Steel Sector Expert Energy Sector Exp. Accredited Energy Auditor (AEA # 0260) Lead Auditor, EMS Mr. Pushkar Khanna 26 yrs. Experience in 2 Mr. Krunal Shah 24 yrs. Experience in 3 Mr. P K Tripathi 4 Mr. J B Sharma BSc, MII Ch > 45 yrs, Ex ED GACL Chlor Alkali Sector Expert 5 Dr. Yogesh Padiya PhD Chem 20 yr in Energy Audits Certified Energy Auditor 6 Mr. Umesh Mishra BE Mec,BoE > 30 yrs Power Sector Expert 7 Mr. Amol Chiplunkar Mtech Eg 10 yrs in Energy Audits Certified Energy Auditor 8 Mr. Rajendra Pandya B.E. Mech. 35 yrs. of Experience Rtd. Sr. Ex GEDA 9 Mr. Nikhil Mohite ME Mech 10 yrs. in Energy Audits Certified Energy Auditor 10 Mr. Samir Shah BE I&C > 20 yrs Textile Sector Expert 11 Mr. K S Seetharaman Bsc (Spl) > 40 yrs Cement Sector Expert 12 Mr. Prashant Saxena BE > 33 yrs Cement Sector Expert 13 Mr. Uday Garge BE Elec 4 yrs in Energy Audits Field study measurements 14 Mr. Pradeep Thakur BE Elec 35 yrs in Energy Audits CEA, Bldgs & TPS 15 Mr. Vaibhav Tupe BE Elec 4 yrs in Energy Audits ECOENERGY SOLUTION Field study measurements

Power Sector Experience Capacity Sr Plant / Station Location, Study 1 Hindustan Zinc ltd, 234 MW Coal CPP Detailed Energy Audit 2 Indrajeet Infra Ltd. 2 x 45 MW CPP Detailed Energy Audit 3 Essar Power ltd, Hazira 500 MW Gas CCGT Detailed Energy Audit 4 Pragati Power Corp. Ltd 330 MW Gas CCGT Mandatory Energy Audit 5 TATA Power Ltd. Trombay 1250 MW Multi fuel PAT M&V Audit 6 3 x 250 MW + 2 x 67.5 CESC Ltd., Kolkata Mandatory Energy Audit 7 Adani Udupi Power Corp. Ltd. 2 x 600 MW TPS, IPP Mandatory Energy Audit 9 Aryan Coal Ltd. 2 x 135 MW, TPS IPP Mandatory Energy Audit 10 ACB Ltd. Washery rejects 2 x 30 MW Mandatory Energy Audit 11 Spectrum Power Ltd 2 x 50 MW, IPP Mandatory Energy Audit 12 TATA Power CGPL Mundra. 5 x 830 MW TPS, IPP Mandatory Energy Audit 13 Hindalco Ind., Renusagar 10 x 80 MW CPP Mandatory Energy Audit 14 1 x 300 MW , Air Cooled Maruti Clean Coal & Power Mandatory Energy Audit

Steel Sector Experience Sr Plant / Station Capacity Year Location, Study 1 Uttam Galwa ltd Steel & Rolling Mill 2012 Detailed Energy Audit 2 Electrotherm ltd, Integrated Steel Plant 2015 Detailed Energy Audit 3 2015 & 2018 2014 & 2016 Nalwa Steel & Power Ltd Steel & Rolling Mill Mandatory Energy Audit 4 Mukand Ltd Steel Plant SS & Alloy Steel Sponge Iron plant Mandatory Energy Audit 5 Shyam Sel & Power ltd 2017 Mandatory Energy Audit 6 Adhunik Metaliks ltd Integrated Steel Plant 2015 Mandatory Energy Audit 7 Mahindra Eugene ltd Steel & Rolling Mill 2014 Detailed Energy Audit 8 SULB Steel, Bahrain Integrated Steel Plant 2015 Detailed Energy Audit 9 MSP Steel & Power Sponge Iron plant 2017 Mandatory Energy Audit 10 Essar Steel ltd, Hazira 10 Million Ton Plant 2018 Mandatory Energy Audit 11 African Foundries, Nigeria Rolling Mill 2018 Detailed Energy Audit 12 Sterlite Ind. Ltd Al Extrusion 2013 Detailed Energy Audit 13 Alumina Hindalco ltd 2018 Mandatory Energy Audit ECOENERGY SOLUTION

Textile & Cement Sector Experience Sr Plant / Station Capacity Location, Study 1 LS Mills ltd Mandatory Energy Audit 2 Vaibhav Laxmi Ltd, Detailed Energy Audit 3 NTC Textile Mills Detailed Energy Audit 1 India Cements Ltd Detailed Energy Audit 2 Binani Cement Ltd Detailed Energy Audit 3 Chittoor Cement Ltd (Lafarge/Nuvoco Cement) Detailed Energy Audit ECOENERGY SOLUTION

Inhouse Audit Instruments Sr. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Instrument List 3-Phase Power Analyzer-Unbalance Power 3-Phase Balance/1-Phase Power Analyzer-Clamp on Meter Ultrasonic Flow Meter Flue Gas Analyzer & Digital Differential pressure meter Pitot Tube Non Contact InfraRed Thermometer Vane type Anemometer Lux Meter Laser Distance Meter GPS Co-ordinator Sling Physchrometer Digital Non-Contact Tachometer Clamp On Meter Earth Tester Meggar Contact Type Thermometer Pressure gauge & Vacuum Gauges Model ALM 31 Nanovip-2 Elcontrol TR-600H 905 L-Shape Testo-805i Testo AM-4201 99 414D Make Krykard ACORN KANE NEVCO Lutron Kusum-Meco Fluke Garmin Zeal Lutron MECO WACO MECO Digitek BAUMER DT2236 3150 DIT99E DTC-605 AL ECOENERGY SOLUTION