Understanding Different Types of Cement for Construction

Cement is a crucial component in concrete and mortar, with various types available based on specific project requirements. Types include Ordinary Portland Cement for general construction, Modified Portland Cement for sulfate resistance, High Early Strength Cement for quick setting, Low Heat Portland Cement for minimal heat generation, and Sulfate Resistant Portland Cement for structures prone to sulfate attack. Each type offers unique properties for different construction needs.

Uploaded on Sep 26, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

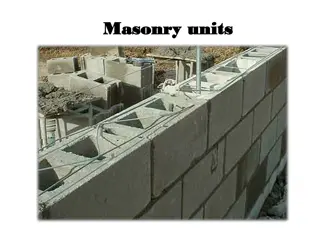

Cement Finely ground powders and all have the important property that when mixed with water a chemical reaction (hydration) takes place. Hydration produces a very hard and strong binding medium for the aggregate particles. The cement to be used in a particular concrete or mortar will be selected on the basis of the particular properties required.

Cement Types Type I (Ordinary Portland cement): Used for general construction work when the special properties of the other types are not required. Normally used for reinforced concrete buildings, bridges, pavements and sidewalks when the soil conditions are normal, for concrete masonry units, and for all uses where the concrete is not subjected to special sulfate hazard, heat of hydration is not objectionable, where freezing-thawing is not expected.

Type II (Modified Portland Cement): It has better resistance to the action of sulfates than normal (ordinary) Portland cement and used where sulfate concentrations in groundwater are higher than normal but not very severe. Generates heat at a slower rate than OPC and is used in certain concrete mass work like retaining walls. Reduced temperature rise is beneficial for hot weather concrete, too.

Type III: (High Early Strength Cement) Used where high early strengths are required at early periods, usually a week or less. It is particularly useful where it is required to remove forms as soon as possible or when the structure must be brought into service quickly. High-early strength makes it possible to reduce the period of protection for concrete during cold weather.

Type IV (Low Heat Portland Cement): It is used where the amount and rate of heat generation must be minimized. Strength is also developed at a slower rate. It is intended for use in massive concrete structures such as dams. Type V (Sulfate Resistant Portland Cement): It is used in structures subject to sulfate attack, chemical plants, etc. It is also resistant to the action of sea water.