Why Choosing a Coiled Tube Manufacturer in Australia is Essential for Your Projects

Quality and reliability become a matter of course in oil and gas, power generation, or even medical equipment manufacturing where coiled tubing is being used to operate smoothly and achieve performance.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

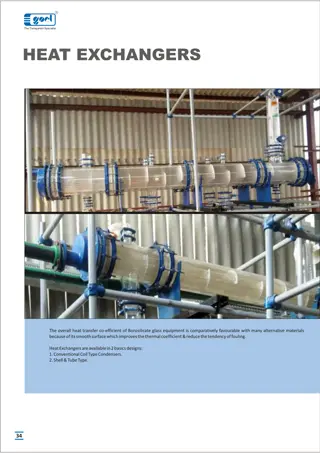

Why Choosing a Coiled Tube Manufacturer in Australia is Essential for Your Projects Quality and reliability become a matter of course in oil and gas, power generation, or even medical equipment manufacturing where coiled tubing is being used to operate smoothly and achieve performance. Coiled tubes come in handy and are used with everything from heat exchangers to fluid transfer systems. Getting the right coil tubing manufacturer makes all the difference in your project. Australia is a country widely known for its high-quality level and high-tech manufacturing. So, selecting the local Coiled Tube Manufacturer would be a considerable advantage. Here's how partnering with an Australian coiled tube manufacturer is pivotal for your projects. 1. Standards of high-quality compliance It has the strictest manufacturing rules and compliance standards worldwide. Australian coiled tube manufacturers pay great attention to quality assurance procedures to comply with the regulations. For such industries as oil and gas or healthcare, where safety and accuracy are concerns, this will provide peace of mind as a result.

For instance, an Australian manufacturer will mostly be ISO 9001 certified. The process ensures that their processes are aligned to international standards. Australian Standards (AS) will mostly align with or be above global benchmarks. From the above, sourcing your coiled tubing from a local manufacturer is sure to have quality products that pass rigorous testing, reducing a possible failure or expensive downtime. 2. Designed for specific uses Manufacturers in Australia, coil tubes, are placed with extreme demands from different projects requiring custom-made solutions that need specific operation. Advanced facilities and engineers designed and made specialized tubing solutions. The requirement for coiled tubes with Australian manufacturers may be met, and in special dimensions, the manufacturer offers coiled tubes that resist corrosion or fabricated tubing to operate in high pressure. It would, therefore, be very valuable to an industry such as mining or chemical processing that has very extreme operating conditions. The level of local and international demands made upon Australian manufacturers ensures that there is flexibility in their production systems to make products that might meet complex project requirements. 3. Shorter Lead Times and Reliable Supply Chains Most application lead times will be shorter than having a local Australian coiled tube manufacturer. Importing goods from overseas usually delays when an ordered part is supplied and may even push the completion of orders beyond set completion dates. There is little doubt that the time taken to ship goods out to clearing customs, sometimes with geopolitical stressors regarding the importation, can push even further back. Local supply chains are robust and reliable, hence the Australian manufacturers. This reduces the chances of any delay and means that raw materials and finished products reach their destinations in good time. This is particularly important in instances such as construction or energy, where any delay would be very costly. 4. E?ective Communication and Coordinating Proximity matters if communication and collaboration are to be e?cient. This would allow real-time discussions with an Australian manufacturer, provide shorter feedback loops, and even visits in person when necessary. Proximity would help the manufacturers understand project requirements better and deliver solutions at the right time. For instance, in situations of design changes or even at times of urgent changes, production with a local manufacturer turns out to be more viable only to implement changes without considerable lags. Close collaboration during the process with engineers ensures that the final product entirely meets your needs. 5. Cost e?ciency through reduced logistics While the initial cost may be higher than importing from overseas, partnering with an Australian coiled tube manufacturer is much cheaper in the long run. Importing products

has other additional costs, such as shipping, insurance, customs duties, and storage fees in case of a backlog. These costs are much lower when one chooses a local manufacturer. In addition, the shorter chain of supply reduces the risk of damage or loss during transit; hence, it saves product replacement or repair costs. Australian manufacturers emphasize quality. That means fewer problems due to defective products, hence fewer long-term expenses from maintenance or replacements. 6. Encourage local industry and sustainability An Australian coiled tube manufacturer contributes to the economy of a country, enhancing employment and innovation. Most of the manufacturers in Australia are willing to work sustainably to reduce carbon footprints and ethically source materials and use energy. Sourcing locally reduces the environmental impacts associated with shipping. It is an investment not only in quality products but corporate responsibility in supporting sustainable practices on the part of an Australian manufacturer. 7. Local Issues Solution Know-how Strange in their nature, Australia's environment can be described as having extreme heat, aggressive marine environments and remote locations. Most industries in such a country face intense pressures. Australian coiled tube manufacturers are conversant with designing products that work well under such conditions. That know-how makes sure that your tubing solutions are rugged, reliable, and robust enough to perform well with the demands of the environment. For example, they can supply coiled tubes from stainless steel or titanium materials, excellent against corrosion and high-pressure conditions. They are very helpful in fields like offshore oil and gas extraction or chemical processing. 8. Availability of Advanced Technology Most of the manufacturing companies in Australia follow this trend: investing in new technologies and machinery to be up-to-date globally. Thus, they gain extra precision and consistency with coiled tubing. Advanced manufacturing techniques involved in this include laser welding and automated coiling to ensure the high quality of products. With the latest technology, Australian manufacturers are in a position to be ahead of the curve of industry trends, offering the best solutions available to clients. This technological advantage can make all the difference in projects that require high-performance materials or intricate designs. Conclusion More than just a procurement decision, it can be the strategic choice to improve the e?ciency, reliability, and success of projects for choosing the coiled tube manufacturer in Australia.

From better quality and more stringent compliance standards to faster lead times and even customized solutions, Australia's manufacturers offer unbeatable benefits. With sustainability, along with local know-how of challenges and access to the latest technology, they are well-placed to meet the toughest challenges in those industries. Partnering with an Australian manufacturer means not just investing in quality products but contributing to the manufacturing sector's growth in Australia and ensuring that your environmental footprint remains low. From energy and healthcare, construction, all the way to any type of coiled tubing usage, a choice of any Australian manufacturer like Znergy Cable will mean that their projects will be built upon a basis of quality, reliability, and innovation. Also Read: Things To Keep in Mind While Buying High Voltage Cable