Understanding Wet Scrubbers in Industrial Air Pollution Control

Wet scrubbers are essential devices for controlling air pollution by removing particles and gases from industrial exhaust streams. They operate by using a scrubbing liquid to collect gases, providing high collection efficiency and low maintenance costs. The design and working principle of wet scrubbers, along with different types categorized by energy levels, are explored in detail.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Table of Contents Introduction Features of Wet Scrubber Designing Procedure Diagrammatical Representation Working Principle Types of Wet Scrubber

Introduction Wet Scrubbers are air pollution control devices for removing particles and gases from industrial exhaust stream. It is operated by introducing the dirty gas stream with a scrubbing liquid as water. Then gases are collected in the scrubbing liquid. Wet scrubbers are usually the most appropriate air pollution control device for collecting both, particulate and gas in a single system alone.

Features 1. Gives high collection efficiency of solid & gaseous pollutant. 2. Provides Maximum pressure drop. 3. Fumes are also be absorbed 4. Maintenance cost is low 5. Complete wetting of the product 6. Emission of minimum product through exhaust 7. Ability to handle high temperature

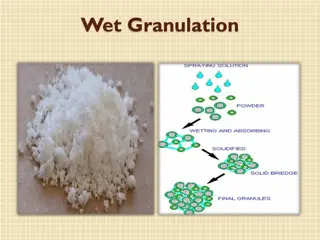

Designing Procedure The design of wet scrubbers depend on the industrial process conditions and the nature of the air pollutants involved in device. Inlet gas features and dust properties (if present) are of more importance. Scrubbers can also be designed to collect particulate matter and gaseous pollutants. The versatility of wet scrubber allows it to be built in numerous configurations. And all are designed to provide good contact between the liquid and polluted gas streams.

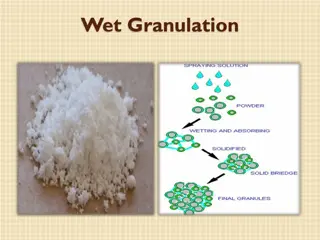

Working Principle It relays on the liquid spray to remove dust particles from gas streams. It is also used for the fume absorption hence it is very useful in fume extraction system. It removes all air pollutants by inertia of diffusional impaction and reactions with absorbent.

Types of Wet Scrubber Since wet scrubbers vary in complexity and its method of operation so we divide it in following categories. Scrubbers for particle collection are categorized by the gas-side pressure drop of the systems. 1. Low-energy scrubbers have pressure drops of less than 12.7 cm of water. 2. Medium-energy scrubbers have pressure drops between 12.7 and 38.1 cm of water. 3. High-energy scrubber have pressure drops greater than 38.1 cm of water.

Advantages Small space requirements: Scrubbers reduce the temp & volume of the unsaturated exhaust streams. So vessel sizes, fans and ducts downstream are smaller than those of other control devices. It results in lower capital costs and more flexibility. No secondary dust sources: Once particulate matter is collected, it cannot escape from hoppers or during transport. Handles high-temperature, high-humidity gas streams: There is no temperature limit or condensation problem can occur in bag-houses

Disadvantages Corrosion Problems: Generally water and dissolved pollutants can form highly corrosive acid solution. So proper construction materials are very important and wet-dry interface areas can also result in corrosion. High power requirements: The high collection efficiencies for particulate matter are attainable only at high pressure drops which results in high operating costs. Water-disposal problems: The settling ponds or sludge clarifier is needed to meet waste-water regulation meter.