Understanding the Impact of Power Quality Issues on Businesses

Power quality problems can lead to significant business disruptions and financial losses, affecting productivity, customer satisfaction, and equipment functionality. Electronic equipment's sensitivity to power disturbances necessitates robust monitoring and analysis to mitigate risks and costs associated with power quality breakdowns.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

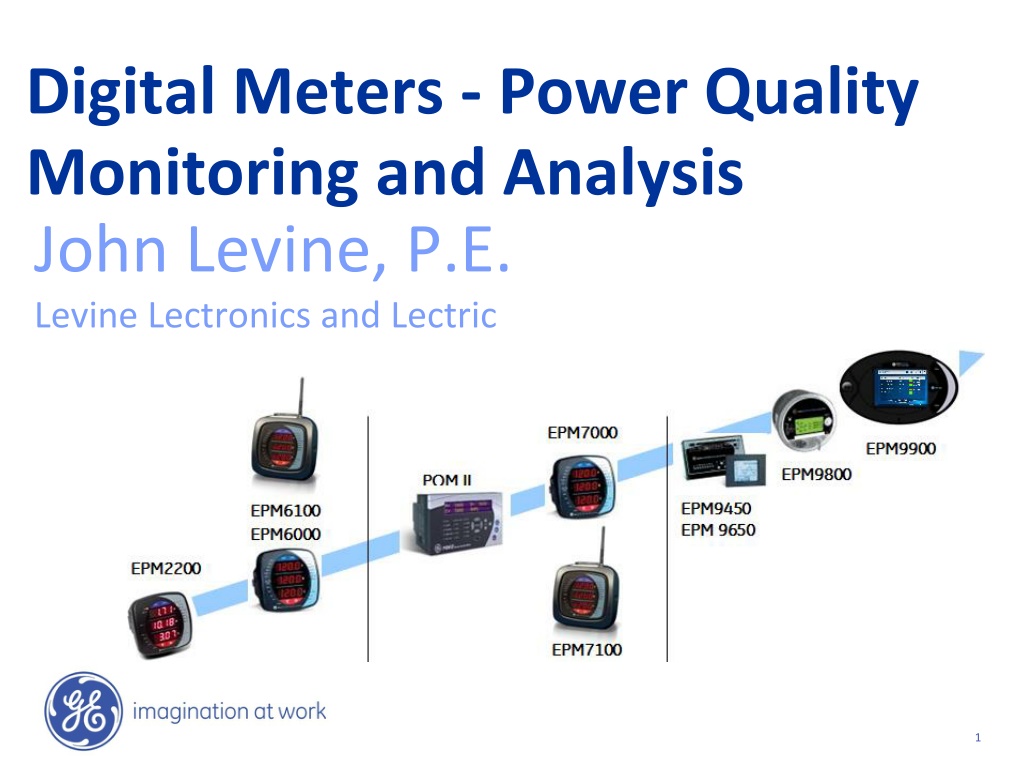

Digital Meters - Power Quality Monitoring and Analysis John Levine, P.E. Levine Lectronics and Lectric 1

Contents Effects of power quality Power Quality definitions revisited What is needed for PQ monitoring ? Summary Monitor and Analyze Power Disturbances, Disruptions & Harmonics 2

PQ is a Business Problem Power Quality issues cause business problems such as: Lost productivity, idle people and equipment Lost orders, good will, customers and profits Lost transactions and orders not being processed Revenue and accounting problems Customer and/or management dissatisfaction Overtime required to make up for lost work time According to Electric Light and Power Magazine, 30 to 40 Percent of All Business Downtime Is Related to Power Quality Problems. 3

Why PQ is such a Big Problem? The sensitivity of today s electronic equipment makes it susceptible to power disturbances For some devices, a momentary disturbance can cause o scrambled data o interrupted communications o a frozen mouse o system crashes and equipment failure 5

PQ Problems are Expensive Berkeley Lab Study Estimates $80 Billion Annual Cost of Power Interruptions Research News, Berkeley Lab, February 2, 2005 $50 billon per year in the USA is lost as a results of power quality breakdowns . Bank of America Report A manufacturing company lost more than $3 million one day last summer in Silicon Valley when the lights went out. New York Times January 2000 A voltage sag in a paper mill can waste a whole day of production - $250,000 loss Business Week, June 17,, 1996 Half of all computer problems and one-third of all data loss can be traced back to the power line Contingency Planning Research, LAN Times 6

Who is Affected? High Cost Facilities Semiconductor plants Pharmaceuticals Data centers o o o Medium Cost Facilities Automotive manufacturing Glass plants Plastics & Chemicals Textiles o Lost production Scrap Costs to restart Labor costs Equipment damage and repair Other costs o o o 7

PQ Definitions Revisited IEEE Categories Std 1159-1995 Short Duration Variations Typical Duration Instantaneous Sag 0.5 30 cycles Momentary Sag 30 cycles 3 sec Temporary Sag 3 sec 1 min 8

PQ Definitions Revisited IEEE Categories Std 1159-1995 Short Duration Variations Typical Duration Instantaneous Sag 0.5 30 cycles Momentary Sag 30 cycles 3 sec. Temporary Sag 3 sec 1 min. Instantaneous Swell 0.5 30 cycles Momentary Swell 30 cycles 3 sec. Temporary Swell 3 sec 1 min. 9

PQ Definitions Revisited IEEE Categories Std 1159-1995 Short Duration Variations Typical Duration Instantaneous Sag 0.5 30 cycles Momentary Sag 30 cycles 3 sec. Temporary Sag 3 sec 1 min. Instantaneous Swell 0.5 30 cycles Momentary Swell 30 cycles 3 sec. Temporary Swell 3 sec 1 min. Momentary Interruptions 0.5 30 cycles Temporary Interruptions 30 cycles 3 sec. 10

PQ Definitions Revisited IEEE Categories Std 1159-1995 Long Duration Variations Typical Duration Sustained interruptions > 1 min Under voltages > 1 min Over voltages > 1 min 11

PQ Definitions Revisited IEEE Categories Std 1159-1995 Long Duration Variations Typical Duration Sustained interruptions > 1 min Under voltages > 1 min Over voltages > 1 min Voltage imbalance Steady state Waveform Distortion 12

PQ Definitions Revisited IEEE Categories Std 1159-1995 Long Duration Variations Typical Duration Sustained interruptions > 1 min Under voltages > 1 min Over voltages > 1 min Voltage imbalance Steady state Waveform Distortion DC offset Steady state Harmonics Steady state Inter harmonics Steady state For Electric Utilities Control of Voltage and Prevention of Outages is Power Quality 13

Sources of PQ Problems Internal Sources Utility Sources Lightning Individual Loads Lighting, Elevators, Coolers, HVAC PF Correction Equipment Uninterruptible Power Supplies Faults Variable Frequency Drives Switching Battery Chargers Large Motors During Startup Electronic Dimming Systems Lighting Ballasts (esp. Electronic) Arc Welders, and Other Arc Devices Medical Equipment, e.g. MRIs and X-Ray Machines Office Equipment and Computers Wiring 14

PQ Problems and Possible Causes Typical problems Disturbance Type Possible Causes Overheated neutral Intermittent lock-ups Frequency deviations Steady-state Shared neutrals Improper or inadequate wiring High source impedance SCR/Rectifiers and notching Harmonics 15

PQ Problems and Possible Causes Typical problems Disturbance Type Possible Causes Overheated neutral Intermittent lock-ups Frequency deviations Steady-state Shared neutrals Improper or inadequate wiring High source impedance SCR/Rectifiers and notching Harmonics Interruption Garbled data Random increase in harmonics levels Utility faults Inrush currents Inadequate wiring 16

PQ Problems and Possible Causes Typical problems Disturbance Type Possible Causes Overheated neutral Intermittent lock-ups Frequency deviations Steady-state Shared neutrals Improper or inadequate wiring High source impedance SCR/Rectifiers and notching Harmonics Interruption Garbled data Random increase in harmonics levels Utility faults Inrush currents Inadequate wiring Intermittent lock-ups Lights flicker Garbled data Sags/Swell Source voltage variations Inrush/surge currents Inadequate wiring 17

PQ Problems and Possible Causes Typical problems Disturbance Type Possible Causes Overheated neutral Intermittent lock-ups Frequency deviations Steady-state Shared neutrals Improper or inadequate wiring High source impedance SCR/Rectifiers and notching Harmonics Interruption Garbled data Random increase in harmonics levels Utility faults Inrush currents Inadequate wiring Intermittent lock-ups Lights flicker Garbled data Sags/Swell Source voltage variations Inrush/surge currents Inadequate wiring Component failure Dielectric breakdown Lock-ups Garbled data Wavy CRTs Impulses EMI/RFI Lightning Load switching Capacitor switching Static discharge Hand-held radios Loose wiring/arcing 18

PQ Problems and Possible Causes Typical problems Disturbance Type Possible Causes Overheated neutral Intermittent lock-ups Frequency deviations Steady-state Shared neutrals Improper or inadequate wiring High source impedance SCR/Rectifiers and notching Harmonics Interruption Garbled data Random increase in harmonics levels Utility faults Inrush currents Inadequate wiring Intermittent lock-ups Lights flicker Garbled data Sags/Swell Source voltage variations Inrush/surge currents Inadequate wiring Component failure Dielectric breakdown Lock-ups Garbled data Wavy CRTs Impulses EMI/RFI Lightning Load switching Capacitor switching Static discharge Hand-held radios Loose wiring/arcing Overheated transformers and motors Voltage and current distortions Garbled data Lock-ups Harmonics Electronic loads SCR/rectifier 19

Major PQ Problems Outages, 6% Spikes, 7% Swells, Sags, 56% 31% Source: EPRI, 1994 Swells Sags (Dips) System fault conditions Associated with system faults Switching on a large capacitor bank Switching of heavy loads Switching off a large load Starting of large motors 20

Cost of Voltage Sags Textile Industry Plastics Industry Glass Industry Process Industry Semiconductors $1k $10k $100k $1M $10M Source: EPRI The Economics of Custom Power , IEEE T&D Show 2003 Losses per Voltage Sag Event 21

Cost of Momentary Outages Cost of Momentary Interuption ($/kW Demand) Category Industrial Semiconductor Manufacturing Electronics Automobile Manufacturing Pharmaceutical Glass Rubber and Plastics Petrochemical Food Processing Textile Metal Fabrication Mining Paper Printing(Newspapers) Minimum Maximum $20.0 $8.0 $5.0 $5.0 $4.0 $3.0 $3.0 $3.0 $2.0 $2.0 $2.0 $1.5 $1.0 $60.0 $12.0 $7.5 $50.0 $6.0 $4.5 $5.0 $5.0 $4.0 $4.0 $4.0 $2.5 $2.0 Momentary Outages create problems when computers and clocks reset, equipment stalls, and work stops. Commercial Hospitals, banks, civil service Communications, information processing Resturants, bars, hotels Commercial shops Source: EPRI The Economics of Custom Power , IEEE T&D 2003 $2.0 $1.0 $0.5 $0.1 $3.0 $10.0 $1.0 $0.5 22

High Speed Waveform Capture High Speed Waveform Capture Is the Most Important PQ Troubleshooting Tool 23

Benefits of Continuous PQ Monitoring Power Quality monitoring provides a continuous Health Check of a facility s power system for example: Harmonic interaction between loads and power conditioning equipment spotted o High Inrush currents from equipment startup detected o Transients from load switching are seen o It provides data to see, diagnose and avert looming problems like squeaky brakes on a car Trends can be detected o JIT equipment maintenance programs can be established o It acts like a Black Box on an airplane to tell you what, when, and where a Power Quality event occurred to prevent it from reoccurring ContinuousPQ Monitoring Detects, Records, and Leads to the Prevention of PQ Problems 24

What is needed for PQ Monitoring? Plus they must PQ Monitors must detect and record the 7 types of PQ problems Be easy to use Be Suitable for continuously monitoring indoors and outdoors Interface with standard PQ analysis Software PQDif format Be fast enough to capture high speed events that produce equipment problems Have enough storage to save the waveforms you need Have PQ analysis tools that produce usable, actionable recommendations Transients Interruptions Sag/Under Voltage Swell/Over Voltage Waveform Distortion Voltage Fluctuations Frequency Variations These include Flicker and Compliance to ITI(CBEMA), IEEE and ISO Standards ITI: Information Technology Industry Council (Computer & Business Equipment Manufacturer s Association) 25

Real Time Field Recorded Events Source: AGA Brazil Meter: EPM9650 Period: Jan 2005 Dec 2005 Continuous Monitoring of the Station for PQ Problems 26

PQ Meter ITI Capture ITI Acceptable Power Disturbance Envelope Damage Inducing Voltage Surges as Recorded Equipment Interrupting Voltage Sags as Recorded ITI: Information Technology Industry Council (Computer & Business Equipment Manufacturer s Association) 27

Summary GE Multilin provides the necessary tools for a successful PQ disturbance analysis and allows users to take remedial actions Symptoms Feels the pulse of the power system network Examinations Accurate Measurement to determine actual state High resolution recordings for longer durations GE Communicator software Diagnosis Remedy Remedial actions 33

Finally If You Can t Measure it You Can t Manage it If You Can Measure it You Can Manage it 34