Understanding Material Failure and Fracture

The process of material failure and fracture, including ductile and brittle fractures, is essential in understanding why materials do not function properly. Ductile fracture involves plastic deformation and slow crack propagation, absorbing a lot of energy. In contrast, brittle fracture occurs rapidly with little energy absorption. The transition between these types can occur with changes in temperature. Examples and images illustrate these concepts.

Uploaded on Oct 02, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

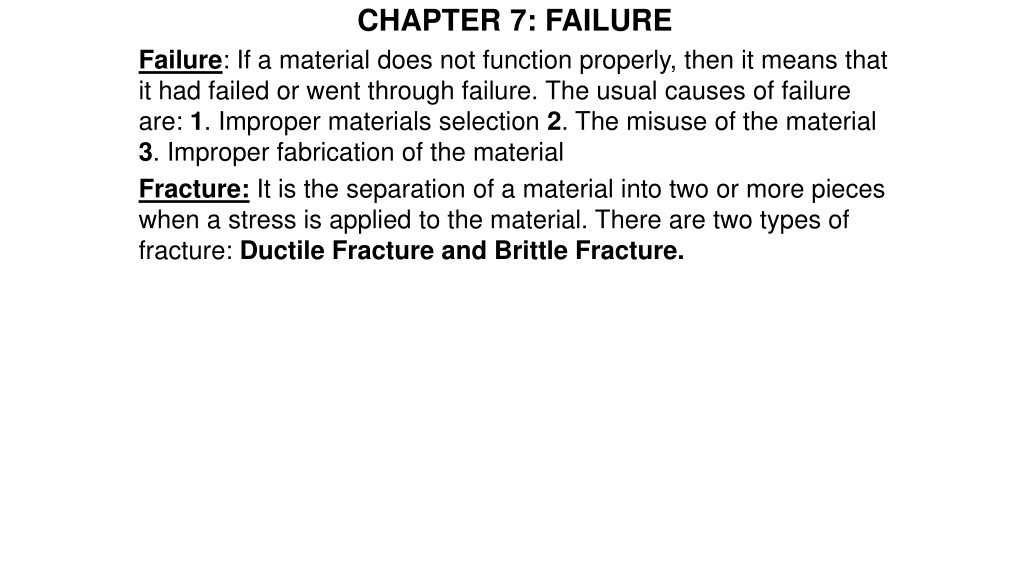

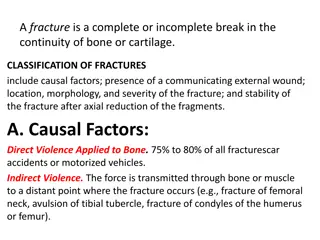

CHAPTER 7: FAILURE Failure: If a material does not function properly, then it means that it had failed or went through failure. The usual causes of failure are: 1. Improper materials selection 2. The misuse of the material 3. Improper fabrication of the material Fracture: It is the separation of a material into two or more pieces when a stress is applied to the material. There are two types of fracture: Ductile Fracture and Brittle Fracture.

CHAPTER 7: FAILURE A. Ductile Fracture: Ductile materials usually have a plastic deformation before fracture. Ductile fracture is a very slow process. It does not happen immediately. The crack of a ductile fracture is stable. In ductile fracture, the material absorbs a lot of energy before the fracture. Figure 8.1 Types of ductile fracture surfaces

CHAPTER 7: FAILURE Figure 8.1 (a) for extremely soft metals, such as pure gold and lead (kur un), and polymers and inorganic glasses at high temperatures. These highly ductile materials neck down to a point fracture with 100% area reduction. Figure 8.1 (b) This is the most common type of fracture for ductile materials.

FAILURE Train wreck at Montparnasse 1895

Schematic representation of the steps in ductile fracture. This fracture has a small neck (boyun). This fracture process occurs in several stages: first the neck forms, then microvoids form, these microvoids enlarge and form a crack which is perpendicular to the applied stress.

B. Brittle Fracture: Brittle materials usually have a very little or no plastic deformation before fracture. Brittle fracture is a very rapid process. The crack propogates immediately. The crack of a brittle fracture is unstable. In brittle fracture, the material absorbs very little energy before the fracture. The crack propogates perpendicular (dikine) to the direction of the applied stress. The brittle fracture surface is very flat. Figure 8.1 (c) The figure of the brittle fracture.

Ductile to Brittle Transition: Some materials may show ductile to brittle transiton. Ductile to Brittle transition occurs usually with decreasing temperature. When temperature of the materials is decreased, the impact energy drops down from a high value (Ductile behavior) to a low value (Brittle behavior).

Fracture of an Aluminum Crank Arm. Bright: Brittle fracture. Dark: Fatigue fracture.

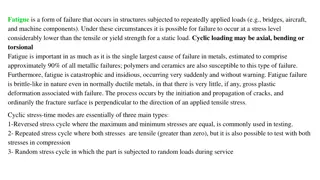

FATIGUE It is a form of failure that occurs in structures such as in bridges, aircraft, etc. Fatigue is usually caused by dynamic and fluctuating (inip kan) stresses. Fatigue can be found in polymers, metals and ceramics. Fatigue occurs after a very long period of repeated stresses on the material.