Tower Fermenter in Microbial Bioreactor Systems

A tower fermenter is a non-mechanically agitated bioreactor used in microbial fermentation processes. It consists of a vertical cylinder with a separator to remove gas bubbles. Different types of tower fermenters include bubble columns, vertical tower beer fermenters, and multistage systems, each serving specific purposes in the production of various products like citric acid, tetracycline, beer, and yeast.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

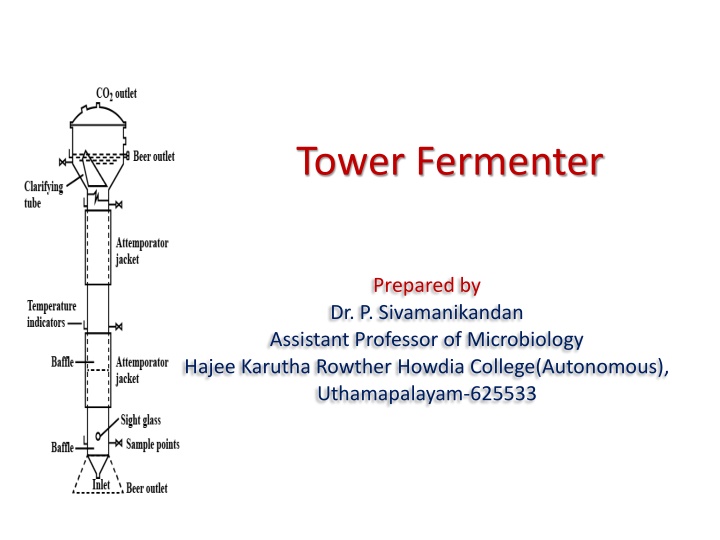

Tower Fermenter Prepared by Dr. P. Sivamanikandan Assistant Professor of Microbiology Hajee Karutha Rowther Howdia College(Autonomous), Uthamapalayam-625533

It is a non -mechanically agitated bioreactor. A simple tower fermentor consists of a long tube with closed ends. In this process yeast flocs are maintained. Sterile air is pumped into the fermenter through its base and it mixes the nutrient medium before going out through a gas outlet at the top. The fermentor consists of a vertical cylinder and the height and diameter of the tube is in the ratio of 10:1.

At the top of the tower a separator is provided to induce the gas bubbles produced by the reaction to combine and escape from the liquid phase. The separator (settle zone) works free of the rising gas, so that the yeast may settle and return to the main body of the tower and clear beer can be removed. There is a water jacket around the vessel to regulate the temperature inside. Tower fermenters are used in the production of citric acid, tetracycline, beer and baker s yeast.

There are three different types of tower fermenters on the basis of their design: (1) Bubble columns, (2) Vertical-tower beer fermenter and (3) Multistage fermenter systems. 1. Bubble Column Tower Fermenters: These are the simplest type of tower fermenters; they consist of glass or metal tubes into which air is introduced at the base These tower fermenters have been used for citric acid and tetracycline production, and for a range of other fermentations based on mycelial fungi.

2. Vertical-Tower Beer Fermenters: These fermenters were designed for beer production and to maximize yeast biomass yields. It has a settling zone free of gas; in this zone, yeast cells settle down to the bottom and return to the main body of the tower fermenter, and clear beer could be removed from the fermenter.

3. Multistage Tower Fermenters: In these Fermenters, a column forms the body of vessel, which is divided into compartments by placing perforated plates across the fermenter. About 10% of the horizontal area of plates is perforated. In a variant of this type of fermenter (down-flow tower fermenter), the substrate is fed in at the top and overflowed through down spouts to the next section, and the air is supplied from the base. These fermenters have been used for continuous culture of E. coli, S. cerevisiae (baker s yeast), and activated sludge.

Thank you Prepared by Dr. P. Sivamanikandan Assistant Professor of Microbiology Hajee Karutha Rowther Howdia College(Autonomous), Uthamapalayam-625533