Threat-Based Flammability Requirements for Military Vehicle Interior Ceilings

This study focuses on developing a test protocol to evaluate the fire thermal and toxicity hazards of ceiling cushioning materials in armored military vehicles during accidental or war fire ignition incidents. The approach involves establishing specific ignition threats and toxicity exposure criteria, aiming to ensure the safety of occupants in such scenarios. Material properties, defined scenarios, acceptance criteria, and design details are outlined to provide a comprehensive understanding of the requirements for military vehicle interior ceilings.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Threat-based Flammability Requirements for Military Vehicle Interior Ceilings J. G. Quintiere, C. Houston, L. Speitel, S. Crowley, R. Lyon, H. Guo Sponsored by United States Army Tank Automotive Research Development and Engineering Center (TARDEC)

Objectives A test protocol to measure the fire thermal and toxicity hazard of ceiling cushioning materials For the occupant compartment of an armored military vehicle subject to accidental or war fire ignition incidents. The ignition threat should not be of significant hazard to the occupants, and Material acceptance criteria must be established with a foundational rationale.

Approach Not adopt standard relative ranking test without relevance to scenario Use material fire properties Extensive listings in reference texts Basis for modeling Underlie material performance in fire Establish ignition threat and toxicity exposure

Defined Scenario 2. Ceiling Alone 1. Fire below

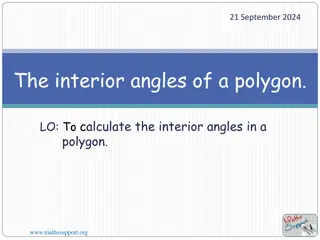

Acceptance Criteria Ignitability No ignition: CHF > CHFcrit = 25 kW/m2 Ignition after 2 min: TRP > TRPcrit = 274 kW-s1/2/m2, OR Safety Factor 30 350 No flame spread over ceiling HRP < HRPcrit = 140/(30 kW/m2 CHF) 70 AEP < AEPcrit = TRP2(30-CHF)HRP/900 kJ/m2 AND No toxic hazard in 5 minutes (Narcotic and acid gases) FEDI < FEDI crit < 1 and FEC < FECcrit < 1 0.3

Design Details Scenario 1: fire below greater hazard than 2 Ignition fire No thermal or toxic hazard to occupants Must impinge on ceiling with flame extension 65 kW heptane pool fire 0.3 m dia., 0.76 m below, flame radial extension 0.32 m. Need to obtain heat flux by this flame to ceiling Cabin Size Smallest (2.2 x 3.2 x 2 m high) with with smallest vents (61 x 15.3 cm)

Ignition Flame Heat Flux 100 Baseline Floor center 4-7-16 80 80 % peak averages 2 Heat Flux kW/m 60 45 kW/m2 Heat flux r = 25 cm 40 Heat flux r = 0 cm 20 12 kW/m2 0 0 100 200 300 400 500 600 700 800 80 Time (s) Heat flux from 65 KW heptane pool fire H = 0.76 m, D = 0.3 m 70 60 50 2 Hasemi et al theory Exp 1 adjacent to wall Exp 2 adjacent to wall Exp 3 centered q" kW/m 40 30 20 ! q = 5.4! Q0.36 in kW, kW/m2 or 24.2 kW/m2. We will round this up to 25 kW/m2. 10 0 0 0.2 0.4 0.6 0.8 1 r m

Flame Spread Critical Energy and Heat Flux Minimum energy release rate per unit area needed to sustain flame spread 70 Flame heat flux in spread

Example: Grey Foam Material CHF kW/m2 TRP kW- s- 1/2/m2 71 HRP -- AEP MJ/m2 Grey Foam 3 3.0 19

Performance of Grey Foam prediction in other tests FAA/OSU: ISO 9705: UL 94: ASTM E84:

Conclusions Engineering design of test protocol for fire hazard. Rationale for test performance is transparent. Methodology can be improved with new knowledge. Material fire properties can be used to judge performance in a fire scenario. This process is superior to existing fire tests and regulations.