Stainless Steel 316L Coils Exporters in India

Shree Venktesh Wires and Steels Pvt Limited, your trusted partner in providing high-quality stainless steel products. Our company prides itself on being one of the leading Manufacturers, Suppliers, Stockists, and Exporters of Stainless Steel 316L Coi

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

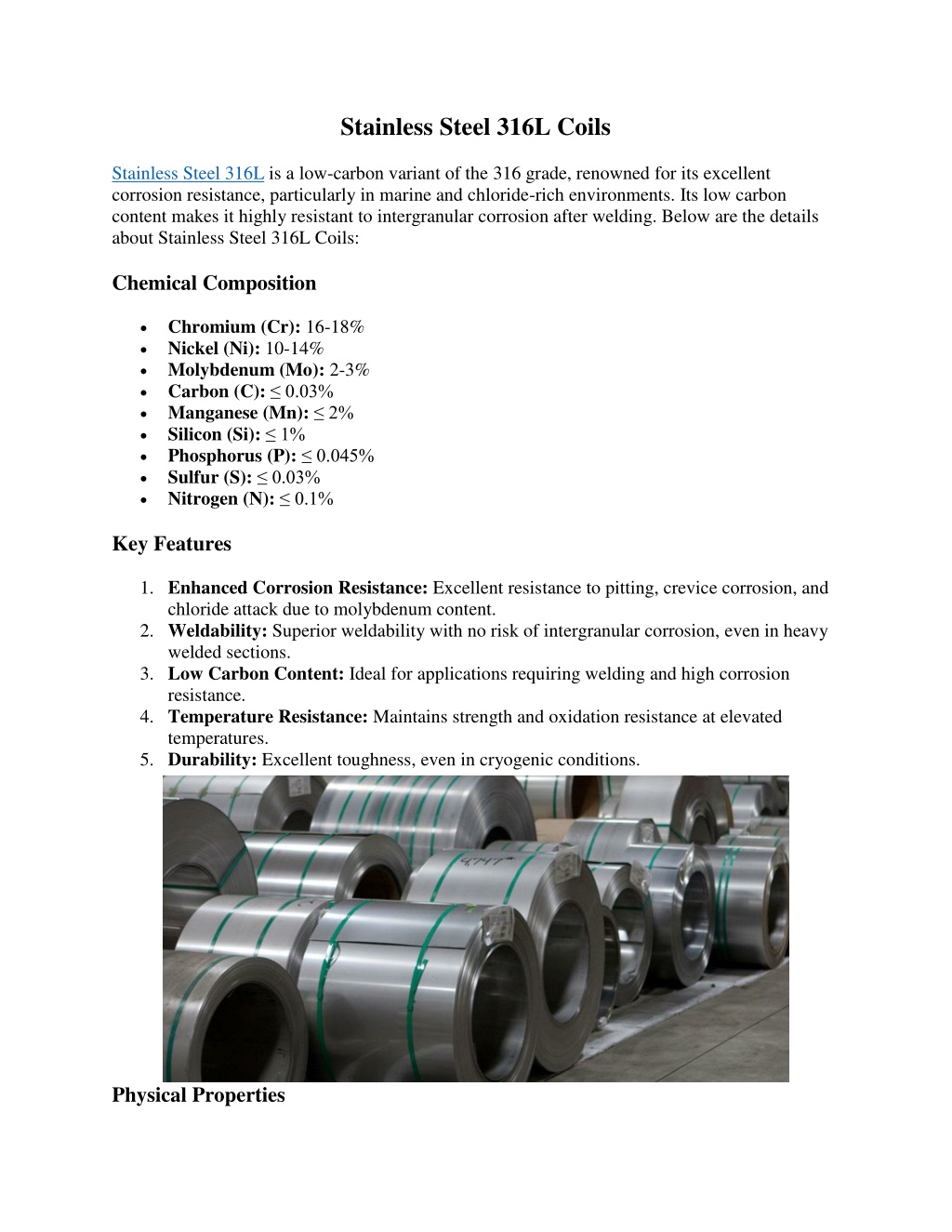

Stainless Steel 316L Coils Stainless Steel 316L is a low-carbon variant of the 316 grade, renowned for its excellent corrosion resistance, particularly in marine and chloride-rich environments. Its low carbon content makes it highly resistant to intergranular corrosion after welding. Below are the details about Stainless Steel 316L Coils: Chemical Composition Chromium (Cr): 16-18% Nickel (Ni): 10-14% Molybdenum (Mo): 2-3% Carbon (C): 0.03% Manganese (Mn): 2% Silicon (Si): 1% Phosphorus (P): 0.045% Sulfur (S): 0.03% Nitrogen (N): 0.1% Key Features 1.Enhanced Corrosion Resistance: Excellent resistance to pitting, crevice corrosion, and chloride attack due to molybdenum content. 2.Weldability: Superior weldability with no risk of intergranular corrosion, even in heavy welded sections. 3.Low Carbon Content: Ideal for applications requiring welding and high corrosion resistance. 4.Temperature Resistance: Maintains strength and oxidation resistance at elevated temperatures. 5.Durability: Excellent toughness, even in cryogenic conditions. Physical Properties

Density: 8 g/cm Melting Point: 1375 1400 C Tensile Strength: 485 MPa (min) Yield Strength: 170 MPa (min) Elongation: 40% (min) Surface Finishes No.1: Hot rolled, annealed, and pickled. 2B: Smooth, cold-rolled finish. BA (Bright Annealed): Reflective, mirror-like surface. No.4 Brushed: Satin finish for aesthetic purposes. Mirror Finish: Highly polished for decorative applications. Applications 1.Marine Industry: Boat fittings, shipbuilding, and equipment exposed to seawater. 2.Chemical Processing: Storage tanks, pressure vessels, and process equipment handling aggressive chemicals. 3.Medical Equipment: Surgical instruments, orthopedic implants, and hospital furniture. 4.Food & Beverage Industry: Processing equipment, kitchenware, and storage tanks. 5.Pharmaceutical Industry: Cleanroom and processing applications. 6.Aerospace & Automotive: Components requiring strength and corrosion resistance under harsh conditions. Comparison with Other Grades 316L vs 304L: 316L offers superior resistance to pitting, crevice corrosion, and chlorides due to added molybdenum. 316L vs 316: 316L has lower carbon content, making it more suitable for welding without the risk of intergranular corrosion. 316L vs Duplex Grades: Duplex stainless steels may provide higher strength and better chloride resistance but at a higher cost. Stainless Steel 316L Coils are widely used in industries requiring high corrosion resistance, durability, and ease of fabrication. Their properties make them ideal for demanding applications in marine, chemical, and pharmaceutical environments.