Quantitative Determination of Nickel in a Compound

In this experiment, you will learn how to quantitatively determine the amount of nickel in a compound. The process involves steps like obtaining and weighing crucibles, homogeneous precipitation, and heterogeneous precipitation. Detailed instructions and images guide you through each step, ensuring accurate results. This hands-on procedure enhances your understanding of analytical chemistry techniques for nickel determination.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Lecture 15a Metal Carbonyl Compounds

Introduction The first metal carbonyl compound described was Ni(CO)4 (Ludwig Mond, ~1890), which was used to refine nickel metal (Mond Process) Ni(CO)4is very volatile (b.p. =40 oC) and highly toxic! Metal carbonyl compounds are used in many industrial processes producing organic compounds i.e., Monsanto process (acetic acid), Fischer Tropsch process (gasoline, ethylene glycol, methanol) or Reppe carbonylation (vinyl esters) from simple precursors (CO, CO2, H2, H2O) Vaska s complex (IrCl(CO)(PPh3)2) absorbs oxygen reversibly and serves as model for the oxygen absorption of myoglobin and hemoglobin (CO and Cl-ligand are disordered in the structure, two CO ligands are shown in the structure)

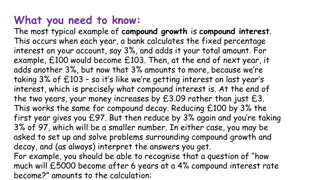

Carbon Monoxide Carbon monoxide is a colorless, tasteless gas that is highly toxic because it strongly binds to the iron in hemoglobin, which converts it to carboxyhemoglobin. The molecule is generally described with a triple bond because the bond distance of d=112.8 pm is too short for a double bond i.e., formaldehyde (H2C=O, d=121 pm). C O The structure on the left is the major contributor because both atoms have an octet in this resonance structure ( =0.122 D). The lone pair of the carbon atom is located in a sp-orbital, which means that it is very basic. HOMO

Bond Mode of CO to Metals The CO ligand usually binds via the carbon atom to the metal xy-plane The lone pair on the carbon forms a -bond with a suitable d-orbital of the metal (i.e., d(x2-y2)) The metal can form a -backbond via the *-orbital of the CO ligand (i.e., d(xy)) Electron-rich metals i.e., late transition metals in low oxidation states are more likely to donate electrons for the -backbonding A strong -backbonding results in a shorter the M-C bond and a longer the C-O bond due to the population of an anti-bonding orbital in the CO ligand (see infrared spectrum) O M C M C O (I) (II)

Synthesis Some compounds can be obtained by direct carbonylation of a metal at room temperature or elevated temperatures. 25 oC/1 atm (CO)= 2057 cm-1 Ni(CO)4 Ni + 4 CO 150 oC/100 atm (CO)= 2013, 2034 cm-1 Fe(CO)5 Fe + 5 CO CrCl3 + Al + 6 CO Cr(CO)6+ AlCl3 (CO)= 2000 cm-1 Re2O7 + 17 CO -1 (CO)= 1983, 2013, 2044 cm Re2(CO)10 + 7 CO2 CH3COOH -1 Fe2(CO)9 (CO)= 1829, 2019, 2082 cm + CO 2 Fe(CO)5 UV-light In other cases, the metal has to be generated in-situ by reduction of a metal halide or metal oxide. Many polynuclear metal carbonyl compounds can be obtained using photochemistry, which exploits the labile character of many M-CO bonds.

Structures I Three bond modes found in metal carbonyl compounds: File:Hexadecacarbonylhexarhodium.svg O O O C C C M M M M M M 3 2 terminal The terminal mode is the most frequently one mode found exhibiting a carbon oxygen triple bond i.e., Ni(CO)4. The double or triply-bridged mode is found in many polynuclear metals carbonyl compounds with an electron deficiency i.e., Rh6(CO)16 (four triply bridged CO groups). Which modes are present in a given compound can often be determined by infrared and 13C-NMR spectroscopy.

Structures II Mononuclear Compounds CO CO CO OC CO CO OC M M M CO OC CO CO OC CO CO CO M(CO)6 (Oh) M(CO)5 (D3h) i.e., Cr(CO)6 M(CO)4 (Td) i.e., Ni(CO)4 i.e., Fe(CO)5 Dinuclear Compounds O C O C O C O C CO CO CO OC CO CO CO OC OC OC CO OC OC M M CO Fe Fe Co Co OC Co Co CO OC CO OC CO CO OC OC CO OC C O CO OC CO OC OC Fe2(CO)9 (D3h) Co2(CO)8 (solid state, C2v) (solution, D3d) Co2(CO)8 M2(CO)10 (D4d) i.e., Re2(CO)10

Infrared Spectroscopy Free CO: 2143 cm-1 Terminal CO groups: 1850-2125 cm-1 2-brigding CO groups: 1750-1850 cm-1 3-bridging CO groups: 1620-1730 cm-1 (CO) [cm-1] Compound d(CO) [pm] Ni(CO)4 Fe(CO)5 Cr(CO)6 Re2(CO)10 Fe2(CO)9 Rh6(CO)16 Ag(CO)+ Cu(CO)2+ 2057 112.6 2013, 2034 112.2, 114.6 2000 114.0 1976, 2014, 2070 112-113, 114.7 1829, 2019, 2082 112.6, 116.0 1800, 2026, 2073 2204 2164 115.5, 120.1 107.7 111.0 Non-classical metal carbonyl compounds can have (CO) greater than the one observed in free CO.

13C-NMR Spectroscopy Terminal CO: 180-220 ppm Bridging CO: 230-280 ppm Examples: M(CO)6: Cr: 211 ppm, Mo: 201.2 ppm, W: 193.1 ppm Fe(CO)5 Solid state: 208.1 ppm (equatorial) and 216 ppm (axial) in a 3:2-ratio Solution: 211.6 ppm (due to rapid axial-equatorial exchange) Fe2(CO)9 (solid state): 204.2 ppm (terminal), 236.4 ppm (bridging) Co2(CO)8 Solid state: 182 ppm (terminal), 234 ppm (bridging) Solution: 205.3 ppm

Collmans Reagent This reagent is obtained from iron pentacarbonyl and sodium hydroxide in an ether i.e., 1,4-dioxane. It exploits the labile character of the Fe-C bond of alkyl iron compounds, which allows for the insertion of a CO ligand generating a RC=O- . Na2Fe(CO)4 Collman's Reagent Fe(CO)5 + 2 NaOH RX RCOCl O R'X H+ RFe(CO)4- (RCO)Fe(CO)4- RCHO R R' D+ O2 X2 RCOOH RCOX R-D Advantages: high degree of chemoselectivity, produces high yields (70-90 %), bears low cost and is relatively environmental friendly

Fischer Tropsch Reaction/Process The reaction was discovered in 1923 The reaction employs hydrogen, carbon monoxide and a metal carbonyl catalyst to form alkanes, alcohols, etc. Ruhrchemie A.G. (1936) Used this process to convert synthesis gas into gasoline using a catalyst Co/ThO2/MgO/Silica gel at 170-200 oC at 1 atm The yield of gasoline was only ~50 % while about 25 % diesel oil and 25 % waxes were formed An improved process (Sasol) using iron oxides as catalyst, 320-340 oC and 25 atm pressure affords 70 % gasoline

Fischer Tropsch Reaction/Process Second generation catalyst are homogeneous i.e., [Rh6(CO)34]2- Union Carbide: ethylene glycol (antifreeze) is obtain at high pressures (3000 atm, 250 oC) O H2 H2 CO CO M C H M M CH3 M COCH3 M CO H2 H2 H2 O H M M CH2 CH3 M CH3 CH2 H2 CO M M OCH3 CH3OH CH4 M COCH2CH3 M H Gasolines Production of long-chain alkanes is favored at a temperature around 220 oC and pressures of 1-30 atm

Monsanto Process (Acetic Acid) This process uses cis-[(CO)2RhI2]- as catalyst to convert methanol and carbon dioxide to acetic acid The reaction is carried out at 180 oC and 30 atm pressure Oxidative Addition (+I to +III) CO Insertion Reductive Elimination (+III to +I) CO Addition Two separate cycles that are combined with each other The BP Captiva Process uses cis-[(CO)2IrI2]- as catalyst

Hydroformylation It uses a cobalt catalyst to convert an alkene, carbon monoxide and hydrogen has into an aldehyde The reaction is carried at moderate temperatures (90-150 oC) and high pressures (100-400 atm) HCo(CO)4 CO HCo(CO)3 RCH2CH2CHO CH2=CHR HCo(CO)3(CH2=CHR) RCH2CH2COCo(H2)(CO)3 H2 RCH2CH2Co(CO)3 RCH2CH2COCo(CO)3 RCH2CH2Co(CO)4 CO

PausonKhand Reaction The Pauson Khand reaction is a [2+2+1] cycloaddition reaction between an alkene, alkyne and carbon monoxide to form an , -cyclopentenone Originally it was catalyzed by dicobalt octacarbonyl, more recently also by Rh-complexes (i.e., Wilkinson s complex with silver triflate as co-catalyst)

Reppe-Carbonylation Acetylene, carbon monoxide and alcohols are reacted in the presence of a catalyst like Ni(CO)4, HCo(CO)4 or Fe(CO)5 to yield acrylic acid esters If water is used instead of alcohols, the carboxylic acid is obtained (i.e., acrylic acid) The BHC process to synthesize of ibuprofen uses a palladium catalyst for the last step to convert the secondary alcohol into a carboxylic acid Green Process because it has 77 % atom economy (99 % after recycling) The previous process (Boots process) displayed an atom economy of 40 % and produced a lot of hazardous waste CO, [Pd] H2, RaneyNi (CH3CO)2O/HF O COOH OH

Doetz Reaction Carbonyl compounds are reacted with phenyl lithium and methyl iodide to form metal-carbene complexes (Fischer carbenes). The addition of an alkyne leads to the formation of a metallacycle. Next, one of the carbonyl groups is inserted into the Cr-C bond. The electrophilic addition of the carbonyl function to the phenyl group affords a naphthalene ring.

Further Reading Werner, H.: Landmarks in Organo-Transition Metal Chemistry, Springer, 2009