Personal Protective Equipment (PPE) Training and Requirements

This information covers the training and requirements related to Personal Protective Equipment (PPE), including the importance of maintaining PPE in serviceable condition, conducting hazard assessments, selecting appropriate PPE, and types of PPE such as eye protection, head protection, and more. Understanding and implementing PPE measures are crucial in ensuring workplace safety and protecting employees from potential hazards.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

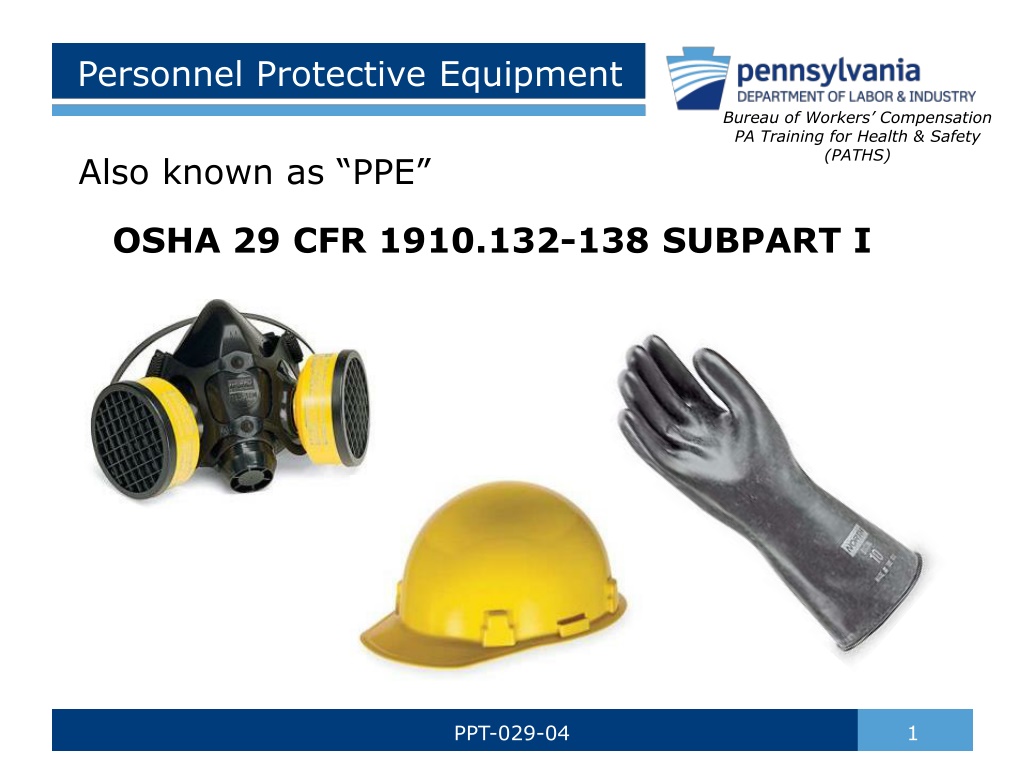

Personnel Protective Equipment Bureau of Workers Compensation PA Training for Health & Safety (PATHS) Also known as PPE OSHA 29 CFR 1910.132-138 SUBPART I PPT-029-04 1

Personal Protective Equipment Part of a series of protection controls: 1.Engineering (example: installation of an exhaust system over a machine producing hazardous vapors) 2. Administrative (example: rotating people through a certain job function) 3.PPE (example: leather gloves, safety shoes) PPT-029-04 2

PPE Requirements Must be kept in serviceable condition: - No rips/tears/cuts - Adjustment straps in place/usable - Viewing lenses not overly-scratched - Not deformed or misshaped Training must be provided and documented (includes equipment-specific training). Hazard assessment must be conducted and certified in writing. PPT-029-04 3

Hazard Assessment Employers must assess the workplace to determine if hazards requiring PPE use are present or likely to be present. If hazards requiring PPE are found or are likely, employers must: - Select and have affected employees use appropriate PPE. -Inform affected employees as to which PPE was selected. -Select PPE that properly fits each affected employee. PPT-029-04 4

Types of PPE Examples: safety glasses face shield hard hat ear plugs rubber gloves safety shoes rubber apron respirator Eye Face - Head - Ear - Hand - Foot - Body - Respiratory - PPT-029-04 5

Eye & Face Protection Safety Glasses Safety Goggles Face Shield PPT-029-04 6

Determining Eye/Face Protection If any objects can contact the eyes during the performance of the job, safety glasses WITH SIDE SHIELDS should be worn. Goggles should be used when working with chemicals or if vapors/mists are present and/or produced. Face shields (along with goggles) should be used when doing grinding operations. PPT-029-04 7

Head Protection Different classes/types of hard hats: Type 1 = helmets with a full brim not less than 1 inches wide Type 2 = brimless helmets with a peak extending forward from the crown Class G = general service, limited/low voltage protection Class E = utility service, high voltage protection Class C = special service, no voltage protection PPT-029-04 8

When to Use Head Protection OSHA 29 CFR 1910.135(a)(1) states, "Each affected employee shall wear protective helmets when working in areas where there is a potential for injury to the head from falling objects." PPT-029-04 9

Wearing Hardhats Backwards Is it OK to wear a hardhat backwards? Only if marked with a "reverse donning arrow; it can be worn frontward or backward in accordance with the manufacturer's wearing instructions. Manufacturers do not recommend that workers wear standard hard hats backwards unless it is necessary for certain job applications, such as welding, where a mask is required. OSHA clearly specifies that workers must wear their hats the way they were designed to be worn, unless the manufacturer states a hat can be worn backward. PPT-029-04 10

Hearing/Ear Protection Earplugs - come in a variety of sizes, shapes and materials. Must be prepared and inserted correctly. Earmuffs Normally consist of rigid, molded plastic ear-cups that seal around the ear using foam or fluid-filled cushions and are held in place with metal or plastic headbands. PPT-029-04 11

More Hearing Protection Semi-Aural Devices consist of pods or flexible tips attached to a lightweight headband. Provides a compromise between earmuffs and earplugs. Can be worn in close quarters, easily removed and replaced and conveniently carried when not in use. One size fits the majority of users. Fit is not compromised by safety glasses or hard hats. PPT-029-04 12

Noise Power mower at 3ft = 107 dB Snowmobile, motorcycle = 100 dB Power saw at 3ft = 110 dB Sandblasting, loud rock concert = 115 dB (Pain begins 125 dB) Pneumatic riveter at 4ft = 125 dB (Even short-term exposure can cause permanent damage. Loudest recommended exposure WITH hearing protection is 140 dB) Jet engine at 100ft, gun blast = 140 dB (Death of hearing tissue is 180 dB) Loudest sound possible 194 dB PPT-029-04 13

Using Hearing Protection Generally, the louder the noise, the shorter the exposure time before you have to use hearing protection. The requirements for noise reduction (including hearing protection) begin: - When noise exposures are at or above 85 dBA time-weighted average, or - There are impulse noise sound pressure levels of 140 decibels peak. PPT-029-04 14

Using Hearing Protection Hearing protection must be made available to employees if they are exposed to noise between 85-90 dBA anytime during their work shift. Hearing protection MUST be used if the exposure level is 90 dBA or higher for any duration during their shift. PPT-029-04 15

Hand Protection Hand protection should be used when workers are at risk of injury to their hands or arms. Example: material handling, chemical use, welding, mechanical jobs, electrical work, cutting materials. PPT-029-04 16

Correct Gloves for Job Need to evaluate the job/task being done and provide the best protection. Cloth or leather gloves should not be used for protection against chemical hazards (use neoprene, nitrile, rubber, etc., depending upon chemical). Surgical gloves are not used on electrical jobs (use heavy duty rubber/insulated labeled for electrical use). Cloth gloves should not be used for material handling (use leather gloves). PPT-029-04 17

Glove Selection Help Consult the manufacturer. Contact your safety department. Website for information about chemical protective gloves: https://www.grainger.com/content/qt-safety- chemical-resistant-gloves-guide-191 PPT-029-04 18

Foot Protection Typical foot injury is caused by object falling fewer than 4 feet; median weight of object is about 65 pounds. Wear appropriate foot guards, safety shoes or boots and leggings for protection from: - falling, rolling, sharp objects - hot, wet, slippery surfaces - molten metal PPT-029-04 19

Safety Shoes Should be sturdy and have an impact-resistant toe. Some have puncture-resistive insoles to protect against puncture wounds. Some types have metatarsal guards. Come in a variety of styles and materials including leather or rubber boots and oxfords. Must comply with any of the following: ANSI Z41-1999, ANSI Z41-1991, ASTM F-2412- 2005, ASTM F-2413-2005. PPT-029-04 20

Body Protection Should be used in the event of: chemical, hot metal or liquid splashes, cuts, acids, intense heat, cold and radiation. A variety of protective clothing is available including: vests, jackets, aprons, coveralls and full body suits. Consult manufacturer s specifications for appropriate use. PPT-029-04 21

Respiratory Protection OSHA 29CFR Part 1910.134, Respiratory Protection Respirators shall be provided when necessary to protect the health of employees from breathable hazards. In the control of those occupational diseases caused by breathing air contaminated with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors, the primary objective shall be to prevent atmospheric contamination. This shall be accomplished as far as feasible by accepted engineering control measures. PPT-029-04 22

Respiratory Protection Respirators shall be used in the following circumstances: Where exposure levels exceed the permissible exposure limit, or PEL, during the time period necessary to install or implement feasible engineering/work practice controls. In regulated areas. Where employer has implemented all feasible engineering and work practice controls and these are not sufficient to reduce exposures to or below the permissible exposure limit. PPT-029-04 23

Respiratory Hazards There are two main types of respiratory hazards: Oxygen Deficiency Airborne Contaminants PPT-029-04 24

Respiratory Hazards Oxygen Deficiency Air is composed of approximately 21% oxygen,78% nitrogen and other trace components. If the oxygen level is less than 19.5 % then you are in an oxygen deficient environment. Only atmosphere supplying PPE can be used when working in an oxygen deficient environment PPT-029-04 25

Respiratory Hazards Airborne contaminants include: Dusts (e.g., from sawing or grinding) Mists (e.g., from spray painting) Vapors (gaseous forms of a liquid) Fumes (e.g., from welding operations) Gases (e.g., nitrogen, methane) Biological (e.g., bacteria & viruses) PPT-029-04 26

Permissable Exposure Limit An example of how to apply the PEL: The OSHA PEL for asbestos = .1 asbestos fiber/Cubic Centimeter (CC) of air. Collection of air samples & laboratory analysis is used to measure asbestos fibers in the work area. If the analysis determines that equal to or greater than .1 fiber/CC of air exist then a respirator must be worn. Respirator selection is based on the level of asbestos fibers identified. PPT-029-04 27

Types of Respiratory PPE Two general categories: Air-purifying respirators Remove contaminants from air through chemical or mechanical means. Atmosphere-supplying respirators Self-contained breathing apparatus, or SCBA, and airline Equipment or SARs. PPT-029-04 28

Assigned Protection Factors The workplace level of respiratory protection that a respirator or class of respirators is expected to provide. Employers must use the OSHA assigned protection factors listed at 29CFR 1910.134 (d) at Table 1. PPT-029-04 29

N95 N95 Simplistic design Bridge has a metal band to allow fitting Filter is effective against dust, particulates & body fluids PPT-029-04 30

Air-purifying Respirators Negative Pressure Respirators Half Face - Covers mouth & nose but not the eyes Full Face - Covers mouth, nose & eyes PPT-029-04 31

Air-purifying Respirators Positive Pressure Respirators Powered-Air Purifying Respirator with Full Face Mask Powered-Air Purifying Respirator with Hood PPT-029-04 32

Supplied Air Respirators Supplied Air Respirator (SAR) Lines up to 300 Work longer in the regulated area Self Contained Breathing Apparatus (SCBA) Cylinder limits time in regulated work area PPT-029-04 33

Initial Medical Evaluation Employee must first receive a medical evaluation from a physician or other licensed health care professional who will determine if they can wear a respirator. Immediate supervisor must obtain a written recommendation from a health care professional on whether or not the employee is medically able to use the respirator. PPT-029-04 34

Fitting the Respirator The fit of a respirator face piece to ensure a good seal is extremely important . A secure fit means the difference between life and death! Since most face pieces fit only a certain percentage of people, it is important that face pieces are tested for each potential user. PPT-029-04 35

Factors Affecting Fit Facial features such as beards, hollow temples, prominent cheekbones, dentures or missing teeth. Under OSHA, could this guy wear a tight fitting respirator? Recent jaw surgery. Chewing of gum or tobacco. No, due to excess facial hair. PPT-029-04 36

Initial Fit Testing Employees must be fit tested before initial respirator use and then annually thereafter. Two types of tests: qualitative and quantitative. Qualitative user determines if he/she can smell testing agent being used. Quantitative instruments detect agent. PPT-029-04 37

Written Respiratory Protection Program OSHA requires that employers establish a written respiratory program documenting each hazard, site by site, based on a work site survey and evaluation. Written program should spell out site-specific procedures that will be implemented to reduce dangers including: Procedures for selecting respirators Medical evaluation of employees required to wear respirators Fit-testing procedures Procedures for proper use of respirators in all situations Procedures and schedules for cleaning, disinfecting, storing, etc. Training Program evaluation procedures PPT-029-04 38

Summary - PPE PPE should be used last in a series of protective measures, following engineering and administrative controls. PPE should not be arbitrarily issued; employees should be given the correct equipment that fits properly. PPE should be in serviceable condition and stored in an area where it cannot be damaged or exposed to the elements. Employees who are given/use PPE should receive appropriate training in the use of that equipment, and training should be documented. Hazard assessments should be performed and documented. PPT-029-04 39

Reference Documents OSHA 29 CFR 1910.132-138, Subpart I ANSI Z41-1999 ANSI Z41-1991 ASTM F-2412-2005 ASTM F-2413-2005 OSHA 3352-02, 2009 PPT-029-04 40

Contact Information Health & Safety Training Specialists 1171 South Cameron Street, Room 324 Harrisburg, PA 17104-2501 (717) 772-1635 RA-LI-BWC-PATHS@pa.gov Like us on Facebook! - https://www.facebook.com/BWCPATHS PPT-029-04 41

Questions PPT-029-04 42