Ointments and Ointment Bases in Pharmaceutics

In the field of pharmaceutics, ointments play a crucial role as semisolid dosage forms for topical application. They serve as vehicles for medicinal substances, offering protective and emollient functions. Ointments are composed of ointment bases, which can be medicated or non-medicated, providing different properties such as emolliency and lubrication. Evaluation of ointments involves assessing drug content, release of medicament from the base, medicament penetration, consistency, absorption into the bloodstream, and irritant effects. Different types of ointment bases include hydrocarbon bases, absorption bases, and water-soluble bases, each with specific characteristics and applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

King Saud University College of Pharmacy Department of Pharmaceutics PHT 312: Pharmaceutics II SEMI-SOLID DOSAGE FORMS: 1- Ointments 2- Creams 3- Gel and Pastes

Semi-solid Dosage Forms Semisolid dosage forms arise from the fact that, within the matrix there are liquid molecules, but it is either solid or liquid-crystalline material blended within the matrix that provides the body or consistency to the matrix. They fulfill a special topical need by being able to cling to the surface of the skin for a protracted period, generally until being washed off or worn off. Lotions have poor adhesiveness and may readily flow off the applied area.

Ointments ointtub Ointments are semisolid preparations for external application to the body. They should be of such composition that they soften, but not necessarily melt, when applied to the skin. Therapeutically, ointments function as protectives & emollients to the skin, but are used primarily as vehicles or bases for the topical application of medicinal substances. eyeointgel Ointments also may be applied to the eye or eyelids.

Ointment Bases Ointments: semisolid preparations intended for external use. (Ophthalmic ointments are a separate classification.) it can be medicated or nonmedicated. If nonmedicated, the ointment is usually referred to as an ointment base. Generally, an ointment is translucent. An ointment base can be used for its emollient or lubricating properties or as the vehicle for a medicated ointment. An emollient makes skin soft and supple probably by occluding the skin surface which prevents moisture loss and allows the underlying material to rehydrate.

Ointment Bases The vehicle of an ointment is known as ointment base. The choice of a base depends upon the clinical indication for the ointment, and the different types of ointment bases are: Hydrocarbon bases. e.g. hard paraffin, soft paraffin. Absorption bases. e.g. wool fat, beewax. Water soluble bases. e.g. macrogols 200,300,400. The medicaments are dispersed in the base and later they get divided after the drug penetration into the living cells of skin.

EVALUATION OF OINTMENTS Drug content Release of medicament from base Medicament penetration Consistency of the preparation Absorption of medicament into blood stream Irritant effect.

Ointment Bases Hydrocarbon bases: water free, oleaginous compounds which used principally for their emollient effect. They are retained on the skin for a long time, do not permit evaporation of moisture from the surface of the skin (occlusive dressing), and are difficult to wash off. Petrolatum, white petrolatum and mineral oil fall into this classification. In general, fluid hydrocarbons, usually 16 to 30 carbon straight-chain and branched molecules are entrapped in a fine crystalline matrix of 30 to 50 carbon molecules. If the base is melted and then slowly cooled, they tend to be more fluid than when rapidly cooled since fewer and larger crystals are formed, resulting in less total solid structure.

Ointment Bases Silicone ointments: contains polydimethylsiloxane oil as the principal ingredient. The semisolid character is due to a wax or other high melting agent which is blended with the silicone. These ointments are also excellent at providing a water- barrier on the surface of the skin and have been used as emollients. On the negative side, hydrocarbon bases and silicone ointments are considered greasy, and they stain clothes. The principal ingredients are not good solvents for drugs and may compromise drug availability. This solubility disadvantage can be overcome by incorporating a miscible cosolvent which possesses a broader capacity to dissolve drugs.

Ointment Bases Absorption bases: two types: (1) those that permit incorporation of aqueous solutions, resulting in a w/o emulsion (Hydrophilic petrolatum and anhydrous lanolin fall into this category) and (2) those that are already w/o emulsions, the so-called emulsion bases, that permit incorporation of a small additional amount of an aqueous solution (lanolin and cold cream are examples of this category). These bases can be used as emollients but are less successful than the hydrocarbon bases which are better able to occlude the skin surface. Absorption bases are not easily washed off with water.

Ointment Bases Absorption bases: They can be used to introduce an aqueous solution into a hydrocarbon base by first incorporating the solution into the absorption base and then incorporating the absorption base into the hydrocarbon base. In this case, an equivalent amount of the hydrocarbon base would be substituted with the absorption base.

Ointment Bases Water-removable bases: o/w emulsions that can be washed off the skin or clothing with water. They are the "water-washable" ointment bases although they contain water-soluble and water-insoluble components. They may be diluted with water or aqueous solutions. An antimicrobial preservative would be incorporated into the aqueous continuous phase of this base. Hydrophilic ointment is the only example of this type of base.

Ointment Bases Water-soluble bases: These bases contain only water- soluble components and therefore can be washed off with water. These are the so-called "greaseless" bases because of the absence of oleaginous materials. Since these bases soften when diluted with water, they are not effective for delivery of aqueous solutions, but are better used for incorporation of nonaqueous or solid substances. Mixtures of the water-soluble polyethylene glycols (PEG's) are found in this category.

Ointment Bases Water-soluble bases: Because PEG is linear polymer, polyethylene glycols of short chain length are liquids and those of long chain length are solids at room temperature. A mixture of different types of can be prepared to have the desired consistency and drug release properties. Many drugs are soluble in the PEG bases. In fact, topical drug availability may be poor due to excessive drug solubility, which translates to "poor vehicle to skin partitioning."

Selection of the Appropriate Base The choice of ointment base depends on several questions: What is the desired drug release rate from the ointment base? Should the base enhance skin absorption of the drug (percutaneous absorption)? e.g., PEG's are believed to be skin penetration enhancers. Should the base occlude the skin? What is the stability of the drug in the base? Does the drug affect the consistency of the base?

Creams Creams are viscous liquid or semisolid emulsions of either the O/W or W/O type. Creams of the O/W type include shaving creams, hand creams, and foundation creams; W/O creams include cold creams and emollient creams

Creams A cream is a topical preparation usually for application to the skin. Creams for application to mucus membranes such as those of the rectum or vagina are also used. Creams may be considered pharmaceutical products as even cosmetic creams are based on techniques developed by pharmacy and unmedicated creams are highly used in a variety of skin conditions (dermatoses). Creams are semi-solid emulsions, that is mixtures of oil and water. They are divided into two types: oil-in-water (O/W) creams which are composed of small droplets of oil dispersed in a continuous aqueous phase, and water- in-oil (W/O) creams which are composed of small droplets of water dispersed in a continuous oily phase.

Creams Oil-in-water creams are more comfortable and cosmetically acceptable as they are less greasy and more easily washed off using water. Water-in-oil creams are more difficult to handle but many drugs which are incorporated into creams are hydrophobic and will be released more readily from a water-in-oil cream than an oil-in-water cream. Water-in-oil creams are also more moisturising as they provide an oily barrier which reduces water loss from the stratum corneum, the outmost layer of the skin.

Uses of creams The provision of a barrier to protect the skin To aid in the retention of moisture (especially water-in- oil creams) Cleansing Emollient effects As a vehicle for drug substances such as local anaesthetics, anti-inflammatories (NSAIDs or corticosteroids), hormones, antibiotics, antifungals or counter-irritants.

Preparation of Ointments and Creams One of two methods is used to prepare these products: the fusion method or the cold incorporation method. Fusion is used for virtually all o/w creams, which are prepared at high temperatures as liquid emulsions and then cooled to the semisolid character at room temperature. Incorporation is used when a drug is to be added to an already prepared ointment or cream system or when the vehicle is heat labile.

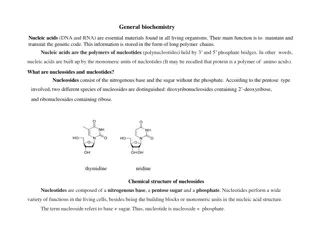

Gel A gel is an apparently solid, jelly-like material formed from a colloidal solution. By weight, gels are mostly liquid, yet they behave like solids due to the addition of a gelling agent. A solid three dimensional network spans the volume of a liquid medium. The network can be composed of a wide variety of materials, including particles, polymers and proteins. Cationic polymers are positively charged polymers. Their positive charges prevent the formation of coiled polymers. Cationic polymers are a main functional component of hair gel, because the positive charged polymers also bind the negatively charged amino acids on the surface of the keratin molecules in the hair.

Types of gels Hydrogel is a network of polymer chains that are water-insoluble, sometimes found as a colloidal gel in which water is the dispersion medium. Hydrogels are superabsorbent (they can contain over 99% water) natural or synthetic polymers. Hydrogels also possess a degree of flexibility very similar to natural tissue, due to their significant water content.

Uses of Hydrogels Common uses of Hydrogel include: Currently used as scaffolds in tissue engineering. When used as scaffolds, hydrogels may contain human cells in order to repair tissue. Environmentally sensitive hydrogels. These hydrogels have the ability to sense changes of pH, temperature, or the concentration of metabolite and release their load as result of such a change. As sustained-release delivery systems Contact lenses (silicone hydrogels)

Uses of Hydrogels Common uses of Hydrogel include: Breast implants Dressings for healing of burn or other hard-to-heal wounds. Wound gels are excellent for helping to create or maintain a moist environment. Common ingredients are e.g. polyvinyl alcohol, sodium polyacrylate and acrylate polymers

Types of gels Organogel is a non-crystalline, non-glassy thermoreversible (thermoplastic) solid material composed of a liquid organic phase entrapped in a three-dimensionally cross-linked network. The liquid can be e.g. an organic solvent, a mineral oil or a vegetable oil. The solubility and particle is important characteristics for the elastic properties and firmness of the organogel. Organogels have potential for use in a number of applications, such as in pharmaceuticals, cosmetics and food.

Types of gels Xerogel is a solid formed from a gel by drying with unhindered shrinkage. Xerogels usually retain high porosity and enormous surface area, along with very small pore size. Many substances can form gels when a suitable thickener or gelling agent is added to their formula. This approach is common in manufacture of wide range of products, from foods to paints, adhesives. In fiber optics communications, a soft gel resembling "hair gel" in viscosity is used to fill the plastic tubes containing the fibers.

Pastes Are semisolid dosage forms that contain one or more drug substances intended for topical application. They are divided into: 1- Fatty pastes (e.g. Zinc Oxide Paste) 2- Pastes made from an aqueous gel (e.g. Carboxymethylcellulose Sodium Paste). Pastes are often used in the treatment of oozing lesions, where they act to absorb serous secretions. Pastes adhere reasonably well to the skin and in some instances make the use of bandages unnecessary.

Physical and Chemical Criteria Stability of the active ingredients Stability of the excipients Visual appearance/Color, Odor, and pH Viscosity Loss of water or volatile vehicle components Phase distribution (homogeneity/phase separation) Particle size distribution of the dispersed phase Particulate contamination Microbial contamination/sterility Release behavior/availability

Preservation of Semisolids Obviously, those semisolids that contain water as a component can support microbial growth with more success than can the hydrophobic semisolids. Sterile preparation would involve microbial filtration of the vehicle, aseptic processing and filling of the container under laminar-flow hoods. Most topical products are not intended to be sterile, but microbial contamination must be controlled. Microbial contamination can cause the development of an odor, a color change, or changes in consistency, with a subsequent change in the drug release rate. Frequently, a chemical antimicrobial preservative is added to inhibit microbial growth.

Preservation of Semisolids Examples of topical preservatives include the parabens, phenols, benzoic acid, sorbic acid, and quaternary ammonium salts (e.g., benzalkonium chloride). Protection from microbial contamination can be accomplished with proper packaging and storage conditions, which should also protect the product from air, light, moisture, heat and interactions between the product and the container material.

Packaging for Semisolids Semisolid products are usually packaged in jars or tubes. Jars For extemporaneous packaging in a jar, use a flexible spatula and force the product down and along the sides of the jar to avoid entrapping air. On an industrial scale, a specified amount of the semisolid is forced into the jar with a pressure-filler. Tubes are also generally filled using a pressure-fill technique and approaching the tube from the open back end (the end opposite from the cap).

Administration of Topicals Topical dosage forms are expensive and it is important for you as a pharmacist to council the patient to receive the maximum benefit. Before application, cleanse the affected area and the healthy skin surrounding it with soap and water unless otherwise directed by a physician or by directions accompanying the medication. Dry the cleansed area. Topical should be applied as a thin film and spread evenly on the skin. Overuse, in general, is a waste of product. When using a solution, two or three drops should be placed on the area. Gentle massaging after application of a topical may be advised to cover the affected area. Wash the medication off your hands with soap and water. Occlusion of the affected area with a bandage or gauze is usually not required and the medicated area should be left uncovered.