Nanofluids Heat Transfer Analysis

Investigating heat transfer and friction losses of nanofluids with different functionalization in annular and single tube passage configurations. Correlating properties with particle characters for potential applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

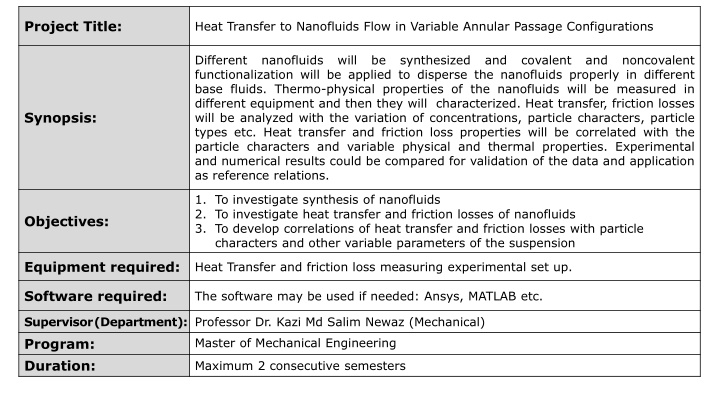

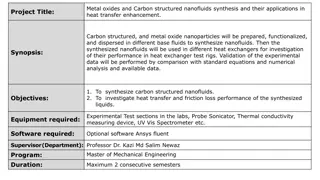

Project Title: Heat Transfer to Nanofluids Flow in Variable Annular Passage Configurations Different functionalization will be applied to disperse the nanofluids properly in different base fluids. Thermo-physical properties of the nanofluids will be measured in different equipment and then they will characterized. Heat transfer, friction losses will be analyzed with the variation of concentrations, particle characters, particle types etc. Heat transfer and friction loss properties will be correlated with the particle characters and variable physical and thermal properties. Experimental and numerical results could be compared for validation of the data and application as reference relations. nanofluids will be synthesized and covalent and noncovalent Synopsis: 1. To investigate synthesis of nanofluids 2. To investigate heat transfer and friction losses of nanofluids 3. To develop correlations of heat transfer and friction losses with particle characters and other variable parameters of the suspension Objectives: Equipment required: Heat Transfer and friction loss measuring experimental set up. Software required: The software may be used if needed: Ansys, MATLAB etc. Supervisor(Department): Professor Dr. Kazi Md Salim Newaz (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Project Title: Heat Transfer to Nanofluids Flow in Variable Single Tube Passage Configurations Different functionalization will be applied to disperse the nanofluids properly in different base fluids. Thermo-physical properties of the nanofluids will be measured in different equipment and then they will losses will be analyzed with the variation of concentrations, particle characters, particle types etc. Heat transfer and friction loss properties will be correlated with the particle characters and variable physical and thermal properties. Experimental and numerical results could be compared for validation of the data and application as reference relations. nanofluids will be synthesized and covalent and noncovalent be characterized. Heat transfer, friction Synopsis: 1. To investigate synthesis of nanofluids 2. To investigate heat transfer and friction losses of nanofluids 3. To develop correlations of heat transfer and friction losses with particle characters and other variable parameters of the suspension Objectives: Equipment required: Heat Transfer and friction loss measuring experimental set up. Software required: The software may be used if needed: Ansys, MATLAB etc. Supervisor(Department): Professor Dr. Kazi Md Salim Newaz (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Heat Transfer and Drag reduction Analyses of suspension Flow in Circular Tube Flow Passage Project Title: Different drag reducing additives will be explored and dispersed in different base fluids. Thermo-physical properties of the suspensions will be measured in different equipment and then they will be characterized. Heat transfer, friction losses will be analyzed with the variation of concentrations, particle characters, particle types etc. Heat transfer and friction loss properties will be correlated with the particle characters and variable physical and thermal properties. Experimental and numerical results could be compared for validation of the data and application as reference relations. Synopsis: 1. To investigate synthesis of drag reducing fluids 2. To investigate heat transfer and friction losses of the suspensions 3. To develop correlations of heat transfer and friction losses of different additives and their mixtures with the additive characters and other variable parameters of the suspension Objectives: Equipment required: Heat Transfer and friction loss measuring experimental set up. Software required: The software may be used if needed: Ansys, MATLAB etc. Supervisor(Department): Professor Dr. Kazi Md Salim Newaz (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Heat Transfer to Fiber Suspension Flow and Application of Fibers in Heat Exchanger Fouling Mitigation Project Title: Heat transfer and friction losses of different fiber suspensions will be investigated. Thermo-physical properties of the suspensions will be measured in different equipment and then they will be characterized. Fouling investigation of mineral salts will be performed. Mitigation of heat exchanger fouling with the fiber and polymeric additives will be investigated. Morphology of the deposition will be investigated. Fouling rate and additives concentrations and qualities will be correlated. Surface morphology and crystallographic study of the deposition will be considered for exploring the avenues of augmented fouling mitigation. Synopsis: 1. To investigate heat transfer and friction losses of the fiber suspension flow in annular passage 2. To investigate mineral fouling in annular flow passage 3. Mitigation of heat exchanger fouling by fiber and natural polymeric additives Objectives: Equipment required: Heat Transfer and fouling investigation test rig. Software required: The software may be used if needed: Ansys, MATLAB etc. Supervisor(Department): Professor Dr. Kazi Md Salim Newaz (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Heat Exchanger Fouling Mitigation by thermal conductive metallic and polymeric coatings Project Title: Heat investigated in a fouling test rig. Fouling of different mineral salts will be investigated. Mitigation of fouling by applying various metallic, nonmetallic, polymeric and composite coatings on investigated. Deposition surface morphology and crystallographic study will be conducted to explore effective coatings for fouling mitigation. transfer from the various coated heat exchanger surfaces will be Synopsis: heat exchanger surfaces will be 1. To investigate heat transfer from the various coated surfaces of heat exchangers 2. To investigate mineral fouling on heat exchanger surfaces 3. To investigate mineral fouling on various coated heat exchanger surfaces for mitigation of fouling Objectives: Equipment required: Heat Transfer and fouling investigation test rig. Software required: The software may be used if needed: Ansys, MATLAB etc. Supervisor(Department): Professor Dr. Kazi Md Salim Newaz (Mechanical) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters