Laboratory Experiments in Particle Physics

The slides depict a series of experiments conducted at the Large Area Detectors Laboratory in June 2015 at UNICAL. The experiments focused on particle physics, detailing the use of detectors, accelerators, and various systems to investigate sub-nuclear phenomena. The images showcase the equipment, processes, and quality control measures involved in studying particles, emphasizing the need for high-resolution detectors with specific characteristics. The laboratory activities involved the design, prototyping, and construction of systems for particle tracking, gas distribution, and control procedures. Overall, the presentation highlights the intricate work and precision essential in particle physics research.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

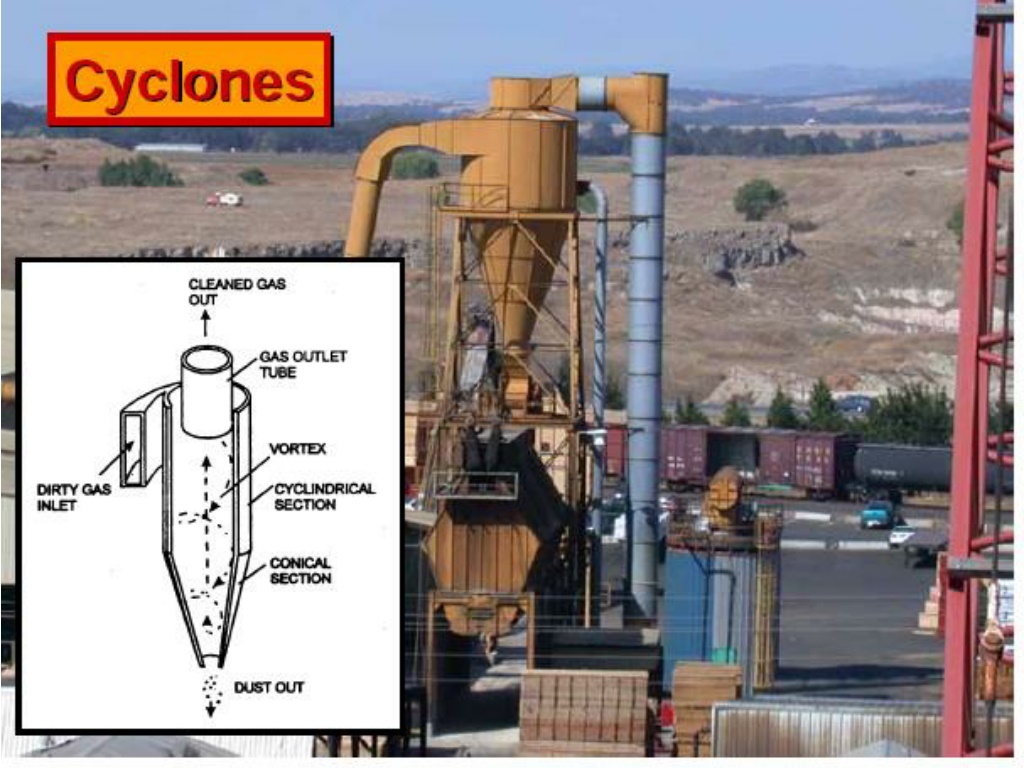

Cyclones Principle The particles are removed by the application of a centrifugal force. The polluted gas stream is forced into a vortex. the motion of the gas exerts a centrifugal force on the particles, and they get deposited on the inner surface of the cyclones

Collection Efficiency In order to calculate the efficiency, first the particle size with 50% collection efficiency (dp50%) as the baseline needs to be determined is dynamic viscosity of air (based on gas temperature) b is inlet width, Ne is the number of effective turns (number of turns the flow makes from the entrance to the midpoint of the core section) Vi is inlet velocity and pis particle density. = + 2 ( ) N L Z e c c H c 6

7 cyclone

o Design factor having greatest effect on collection efficiency is cyclone diameter. o Smaller dia, higher is efficiency, because centrifugal action increase with decreasing radius of rotation. o Cyclone efficiencies > 90 % with particle dia of 10 o > 95 % with particle dia 20 .

o High efficiency- smaller body dia to create greater separating force. o Increase collection efficiency, if increase in dust particle size, dust particle density, gas inlet velocity, inlet dust loading, cyclone body length o Decrease collection efficiency due to increase in cyclone dia, gas outlet dia, inlet width, and inlet area

Problem A cyclone with a flow rate of 150 m3/min has an efficiency of 80%. Estimate the efficiency if the flow rate is doubled.

Solution Step 1 Q1 = 150 m3/min Q2 = 300 m3/min Pt1 = 100% - 80% = 20% Pt2/Pt1 = (Q1/Q2)0.5 Step 2 Final Efficiency = 1- Pt2 = 86%

Problem Design of Cyclone Body diameter = 0.75 m Flow rate = 2.75 m3/s p = 1600 kg/m3 g = 1.1 kg/m3 = 2.5*10-5 kg/m-s High throughput H = 0.8 * body diameter W = 0.35 * body diameter Lb = 1.7 * body diameter Lc = 2.0 * body diameter Calculate the diameter of particle with 50% efficiency

Solution Step 1: Inlet Velocity = Q/A = 17.46 m/s Step 2: Number of effective turns Ne = (Lb + Lc/2)/H Ne = 3.375 Step 3: Diameter of particle dpc = 10 m

Operating problems o Erosion o Corrosion o Material build up

Advantages of Cyclones Cyclones have a lost capital cost Reasonable high efficiency for specially designed cyclones. They can be used under almost any operating condition. Cyclones can be constructed of a wide variety of materials. There are no moving parts, so there are no maintenance requirements. Require less floor area. Simple construction and maintenance. Can handle large volume of gas at high temp.

Disadvantages of Cyclones They can not be used for small particles High pressure drops contribute to increased costs of operation. Requires large head room. Less efficiency for smaller particles (<10 m). Sensitive to variable dust load and flow rate.

Applications o Control gas borne particulates from industries like cement, feed and grain processing, food and beverage processing, mineral processing, paper and textile industries and wood working industries. o Used in recovery of catalyst ducts in petroleum industry and reduction of fly ash emission.