JCB VM115 TIER Ⅲ VIBROMAX Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

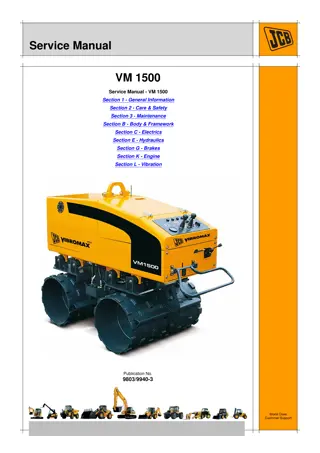

Service Manual VM 115 - TIER III Service Manual - VM 115 - TIER III Section 1 - General Information Section 2 - Care and Safety Section 3 - Maintenance Section B - Body and Framework Section C - Electrics Section E - Hydraulics Section F - Transmission Section H - Steering Section K - Engine Section L - Vibration Publication No. 9813/0700 World Class Customer Support Copyright 2004 JCB SERVICE. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB SERVICE. Issued by JCB Technical Publications, JCB Aftermarket Training, Woodseat, Rocester, Staffordshire, ST14 5BW, England. Tel +44 1889 591300 Fax +44 1889 591400

Section 1 - General Information Notes: 1-0 1-0 9813/0700

Section 1 - General Information Contents Introduction About this Manual ...................................................................................... 1-1 Machine Model and Serial Number .......................................................1-1 Using the Service Manual .....................................................................1-1 Section Numbering ................................................................................1-1 Left Side, Right Side ..............................................................................1-2 Cab/Canopy ..........................................................................................1-2 Cross References ..................................................................................1-2 Identifying Your Machine ........................................................................... 1-3 Machine Identification Plate ..................................................................1-3 Component Identification Plates ............................................................1-4 JCB Engine Identification ......................................................................1-5 Page No. Service Tools Numerical List ............................................................................................ 1-7 Tool Detail Reference ................................................................................ 1-9 Section B - Body and Framework ..........................................................1-9 Section C - Electrics ............................................................................1-13 Section E - Hydraulics .........................................................................1-14 Torque Settings Zinc Plated Fasteners and Dacromet Fasteners ..................................... 1-19 Introduction ..........................................................................................1-19 Bolts and Screws .................................................................................1-19 Vibromax Specific Torque Settings .......................................................... 1-23 Hydraulic Connections ............................................................................. 1-25 'O' Ring Face Seal System ..................................................................1-25 'Torque Stop' Hose System .................................................................1-28 1-i 1-i

Section 1 - General Information Introduction About this Manual Machine Model and Serial Number Finally, please remember above all else safety must come first! This manual provides information for the following model(s) in the JCB machine range: Section Numbering T11-005 The manual is compiled in sections, the first three are numbered and contain information as follows: VM 115 from SN 1705097 onwards. Using the Service Manual General Information - includes torque settings and service tools. Care and Safety - includes warnings and cautions pertinent to aspects of workshop procedures etc. Maintenance - includes service schedules and recommended lubricants for all the machine. 1 T11-004 This publication is designed for the benefit of JCB Distributor Service Engineers who are receiving, or have received, training by JCB Technical Training Department. 2 3 These personnel should have a sound knowledge of workshop practice, safety procedures, and general techniques associated with the maintenance and repair of hydraulic earthmoving equipment. The remaining sections are alphabetically coded and deal with Dismantling, Overhaul etc. of specific components, for example: The illustrations in this publication are for guidance only. Where the machines differ, the text and/or the illustration will specify. Attachments Body and Framework, etc. A B General warnings in Section 2 are repeated throughout the manual, as well as specific warnings. Read all safety statements regularly, so you do not forget them. Section contents, technical data, circuit descriptions, operation descriptions etc. are inserted at the beginning of each alphabetically coded section. Renewal of oil seals, gaskets, etc., and any component showing obvious signs of wear or damage is expected as a matter of course. It is expected that components will be cleaned and lubricated where appropriate, and that any opened hose or pipe connections will be blanked to prevent excessive loss of hydraulic fluid and ingress of dirt. Where a torque setting is given as a single figure it may be varied by plus or minus 3%. Torque figures indicated are for dry threads, hence for lubricated threads may be reduced by one third. The manufacturer's policy is one of continuous improvement. The right to change the specification of the machine without notice is reserved. No responsibility will be accepted for discrepancies which may occur between specifications of the machine and the descriptions contained in this publication. 1-1 1-1 9813/0700

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Section 1 - General Information Introduction About this Manual Left Side, Right Side In this manual, 'left' A and 'right' B mean your left and right when you are seated correctly in the machine. Fig 1. Cab/Canopy T1-003_2 This manual frequently makes references to the cab. For instance, 'do not operate the machine without a manual in the cab'. It should be noted that these statements also apply to canopy build machines. Cross References T1-004_2 In this publication, page cross references are made by presenting the subject title printed in bold, italic and underlined. It is preceeded by the 'go to' symbol. The number of the page upon which the subject begins, is indicated within the brackets. For example: K References ( T T 1-2). K Cross 1-2 1-2 9813/0700

Section 1 - General Information Introduction Identifying Your Machine Identifying Your Machine Machine Identification Plate Typical Product Identification Number (PIN) Your machine has an identification plate mounted as shown. K K Fig 2. ( T T 1-3). 1 2 3 C 4 JCB VM115 01801240 The machine and engine serial numbers can help identify exactly the type of equipment you have. World Manufacturer Identification (JCB) 1 Machine Type and Model (VM115 = VM115) 2 Randomly Generated Check Letter 3 Machine Serial Number (01801240) 4 Fig 2. 1-3 1-3 9813/0700

Section 1 - General Information Introduction Identifying Your Machine Component Identification Plates 3 5 6 1 7 4 2 844210-2 Fig 3. Engine serial number Drum drive motor serial number Steering unit serial number Rear axle serial number Vibration motor serial number Hydraulic pump serial number Axle hydraulic drive motor serial number 1 2 3 4 5 6 7 1-4 1-4 9813/0700

Section 1 - General Information Introduction Identifying Your Machine JCB Engine Identification Engine Data Plate Each JCB Engine has an emissions legislation lable. K K Fig 4. ( T T 1-5) D021990 Fig 4. 1-5 1-5 9813/0700

Section 1 - General Information Introduction Identifying Your Machine Page left intentionally blank 1-6 1-6 9813/0700

Section 1 - General Information Service Tools Numerical List The tools listed in the table are special tools required for carrying out the procedures described in this manual. These tools are available from JCB Service. details of all tools, including the content of kits and sets, refer to Tool Detail Reference, Section 1. Note: Tools other than those listed will be required. It is expected that such general tools will be available in any well equipped workshop or be available locally from any good tool supplier. Some tools are available as kits or sets, the part numbers for parts within such kits or sets are not listed here. For full Part Number - - - - - - Description See Section Bonded Washers - see Tool Detail Reference (Section 1) for content Female Cone Blanking Caps - see Tool Detail Reference (Section 1) for content Female Connectors - see Tool Detail Reference (Section 1) for content Hydraulic Flow Test Equipment - see Tool Detail Reference (Section 1) for content Male Adapters - BSP x BSP - see Tool Detail Reference (Section 1) for content Male Adapters - BSP x NPT (USA only) - see Tool Detail Reference (Section 1) for content Male Cone Blanking Caps - see Tool Detail Reference (Section 1) for content Pressure Test Points - Adaptors - see Tool Detail Reference (Section 1) for content Pressure Test Points - 'T' Adaptors - see Tool Detail Reference (Section 1) for content Rivet Nut Tool - see Tool Detail Reference (Section 1) for content Hand Cleaner Hydraulic Circuit Pressure Test Kit - see Tool Detail Reference (Section 1) for content Hose Gauge Gauge Digital Tachometer Hyd. Oil Temperature Probe Fluke Meter Gauge E E E E E E - - - - 4104/1310 892/00253 892/00254 892/00279 892/00280 892/00284 892/00285 892/00298 892/00346 E E E B B E E E E C C C E E B B B B B 892/00347 892/00842 892/00843 892/00845 892/00846 892/00847 Connector Glass Lifter Folding Stand for Holding Glass Cartridge Gun Glass Extractor (Handles) Nylon Spatula 1-7 1-7 9813/0700

Section 1 - General Information Service Tools Numerical List Part Number Description See Section 892/00848 892/00849 892/01246 892/01247 892/12345 926/15500 992/12300 992/12400 992/12800 992/12801 993/68100 Wire Starter Braided Cutting Wire Vibromax male to JCB female threaded adaptor JCB male to Vibromax female threaded adaptor Frequency and Vibration Measuring Tool Rubber Spacer Blocks 12V Mobile Oven 24V Static Oven (2 Cartridge) Cut-Out Knife 'L' Blades Slide Hammer Kit - see Tool Detail Reference (Section 1) for content B B E E E B B B B B B 1-8 1-8 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Tool Detail Reference Section B - Body and Framework Note: Not all service tools are illustrated. Fig 5. 993/68100 Slide Hammer Kit 993/68101 993/68102 993/68103 993/68104 993/68105 993/68106 Slide Hammer End Stops Adaptor - M20 x 5/8" UNF Adaptor - M20 x 1" UNF Adaptor - M20 x M20 Adaptor - M20 x M24 993/68107 993/68108 993/68109 993/68110 993/68111 Bar - M20 x M20 X 800 mm Adaptor - M20 x 7/8" UNF Adaptor - M20 x M12 Adaptor - M20 x 5/8" UNF (Shoulder) Adaptor - M20 x 1/2" UNF 1 2 3 4 5 6 7 8 9 10 11 826/01099 826/01101 826/01102 826/01103 826/01104 826/01105A - M6 x 16 mm Rivet Nut M6 x 19 mm Rivet Nut M8 x 18 mm Rivet Nut M8 x 21 mm Rivet Nut M10 x 23 mm Rivet Nut M10 x 26 mm Rivet Nut Installation Tool available from: Bollhoff Fastenings Ltd (www.bollhof.com) 1 2 Fig 6. Rivet Nut Tool Minimum 2 off - Essential for glass installation, 2 required to handle large panes of glass. Ensure suction cups are protected from damage during storage. Fig 7. 892/00842 Glass Lifter 1-9 1-9 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Fig 11. 892/00847 Nylon Spatula General tool used for smoothing sealants - also used to re-install glass in rubber glazing because metal tools will chip the glass edge. Fig 8. 892/00843 Folding Stand Essential for preparing new glass prior to installation. Fig 12. 892/00848 Wire Starter Used to access braided cutting wire through original polyurethane seal. K K Fig 13. ( T T 1-11). Fig 9. 892/00845 Cartridge Gun Hand operated. Essential for the application of sealants, polyurethane materials etc. Fig 10. 892/00846 Glass Extractor (Handles) Used with braided cutting wire to cut out broken glass. K K Fig 13. ( T T 1-11). 1-10 1-10 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Fig 16. 992/12400 Static Oven 240V Required to pre-heat adhesive prior to use. No plug supplied. Fig 13. 892/00849 Braided Cutting Wire Consumable heavy duty cut-out wire used with the glass extraction tool. K K Fig 10. ( T T 1-10). Approx 25 m length. Note: 110V models available upon request - contact JCB Technical Service. Fig 14. 926/15500 Rubber Spacer Blocks Used to provide the correct set clearance between glass edge and cab frame. Unit quantity = 500 off. Fig 17. 992/12800 Cut-Out Knife Used to remove broken glass. Fig 15. 992/12300 Mobile Oven 12V 1 cartridge capacity. Required to pre-heat adhesive prior to use. It is fitted with a male plug (703/23201) which fits into a female socket (715/04300). Fig 18. 992/12801 'L' Blades 25 mm (1 in.) cut. Replacement blades for cut-out knife. K K Fig 17. ( T T 1-11). Unit quantity = 5 off. 1-11 1-11 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Fig 19. 4104/1310 Hand Cleaner Special blend for the removal of polyurethane adhesives (454g; 1 lb tub). 1-12 1-12 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Section C - Electrics Note: Not all service tools are illustrated. Fig 20. 892/00298 Fluke Meter Fig 21. 892/00285 Hydraulic Temperature Probe Fig 22. 892/00284 Venture Microtach Digital Tachometer 1-13 1-13 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Section E - Hydraulics Note: Not all service tools are illustrated. Male Adapters - BSP x BSP 3/8 in. x 1/4 in. 3/8 in. x 3/8 in. 3/8 in. x 3/8 in. taper 1/2 in. x 1/4 in. 1/2 in. x 3/8 in. 1/2 in. x 1/2 in. 5/8 in. x 1/2 in. 3/4 in. x 3/8 in. 3/4 in. x 1/2 in. 3/4 in. x 3/4 in. 3/4 in. x 1 in. 3/4 in. x 1.1/4 in. 1 in. x 1.1/4 in. 1606/2052 1604/0003A 892/00071 1606/0004 1606/0007A 1604/0004A 1606/0017 1606/0008 1606/0009 1604/2055 1606/0012 1606/0014 1606/0015 Fig 23. Male Adaptors Male Adapters - BSP x NPT (USA only) 3/8 in. x 1/4 in. 1/2 in. x 1/4 in. 3/8 in. x 3/8 in. 1/2 in. x 3/8 in. 816/00439 816/00440 816/15007A 816/15008 892/00255 892/00256 892/00257 892/00258 816/15118 892/00259 892/00260 892/00261 1/4 in. BSP x Test Point 3/8 in. BSP x Test Point 1/2 in. BSP x Test Point 5/8 in. BSP x Test Point 3/4 in. BSP x Test Point 1 in BSP x Test Point 1.1/4 in. BSP x Test Point 5/8 in. UNF x Test Point Fig 24. Pressure Test Adapters 816/55045 816/55038 816/55040 892/00263 892/00264 1/4 in. M BSP x 1/4 in. F BSP x Test Point 3/8 in. M BSP x 3/8 in. F BSP x Test Point 1/2 in. M BSP x 1/2 in. F BSP x Test Point 5/8 in. M BSP x 5/8 in. F BSP x Test Point 3/4 in. M BSP x 3/4 in. F BSP x Test Point 892/00265 892/00266 892/00267 1 in. M BSP x 1 in. F BSP x Test Point 1.1/4 in. M BSP x 1.1/4 in. F BSP x Test Point 1.1/4 in. M BSP x 1.1/2 in. F BSP x Test Point Fig 25. Pressure Test 'T' Adapters 1-14 1-14 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference 892/00047 892/00048 892/00049 816/50043 892/00051 816/50005 816/60096 816/00017 3/8 in. BSP (A) x 1/4 in. BSP (B) 1/2 in. BSP (A) x 1/4 in. BSP (B) 5/8 in. BSP (A) x 1/4 in. BSP (B) 3/4 in. BSP (A) x 1/4 in. BSP (B) 1 in. BSP (A) x 1/4 in. BSP (B) 1/2 in. BSP (A) x 1/2 in. BSP (B) 3/4 in. BSP (A) x 3/4 in. BSP (B) 1 in. BSP (A) x 1 in. BSP (B) Fig 26. 'T' Adapters 892/00055A 892/00056A 892/00057 892/00058A 892/00059A 892/00060 1/4 in. BSP 3/8 in. BSP 1/2 in. BSP 5/8 in. BSP 3/4 in. BSP 1 in. BSP Fig 27. Female Blanking Caps 816/90045 816/00189A 816/00190A 816/90022 816/90274 816/90205 1/4 in. BSP 3/8 in. BSP 1/2 in. BSP 5/8 in. BSP 3/4 in. BSP 1 in. BSP Fig 28. Male Cone Blanking Caps 892/00074 892/00075 892/00076 892/00077 3/8 in. BSP x 3/8 in. BSP 1/2 in. BSP x 1/2 in. BSP 5/8 in. BSP x 5/8 in. BSP 3/4 in. BSP x 3/4 in. BSP Fig 29. Female Connectors 1406/0011 1406/0018 1406/0014 1406/0021 1406/0029 1/4 in. BSP 1/2 in. BSP 5/8 in. BSP 3/4 in. BSP 1.1/4 in. BSP Fig 30. Bonded Washers 1-15 1-15 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference 892/00268 892/00269 892/00273 892/00293 892/00270 1406/0021 1604/0006A 1612/2054 892/00271 892/00272 816/20008 892/00275 892/00276 892/00277 1606/0015 892/00078 1604/0008 1604/0008 816/20013 Flow Monitoring Unit Sensor Head 0 - 100 l/min (0 - 22 UK gal/min) Sensor Head 0 - 380 l/min (0 - 85.5 UK gal/min) Connector Pipe Load Valve Bonded Washer Adapter 3/4 in M x 3/4 in M BSP Adapter 3/4 in F x 3/4 in M BSP Adapter 3/4 in F x 5/8 in M BSP Adapter 5/8 in F x 3/4 in M BSP Adapter 3/4 in F x 1/2 in M BSP Adapter 1/2 in F x 3/4 in M BSP Adapter 3/4 in F x 3/8 in M BSP Adapter 3/8 in F x 3/4 in M BSP Adapter 1.1/4 in M BSP x 1 in M BSP Connector 1 in F x 1 in F BSP Adapter 1 in M x 1 in M BSP Adapter 1 in M x 3/4 in M BSP Adapter 3/4 in F x 1 in M BSP Fig 31. Flow Test Equipment 892/00201 Replacement Gauge 0-20 bar (0-300 lbf/in2) 892/00202 Replacement Gauge 0-40 bar (0-600 lbf/in2) 1 892/00203 Replacement Gauge 0-400 bar (0-6000 lbf/in2) Replacement Hose Seal Kit for 892/00254 (can also be used with probe 892/00706) Test Probe Connector - Hose to gauge 2 3 892/00254 993/69800 892/00706 892/00347 Fig 32. 892/ 00253 Hydraulic Circuit Pressure Test Kit 1-16 1-16 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference 892/00280 Pressure Gauge 0-600 bar (0-9000 lbf/in2) 892/00279 Pressure Gauge 0-400 bar (0-6000 lbf/in2) 892/00346 Pressure Gauge 0-70 bar (0-1000 lbf/in2) Connector Hose 892/00347 892/00254 Fig 33. Hydraulic Circuit Test Gauges and Connections Fig 34. Adaptor (item A) Fig 35. 892/12345 Frequency and Vibration Measuring Tool Allows the service engineer to measure the frequency of the vibrating drum (it will also measure engine speed on any type of machinery). Item A Part No 892/01247 JCB male to Vibromax female threaded adaptor - Connects JCB female test hose to male Vibromax test point 892/01246 Vibromax male to JCB female threaded adaptor - Connects Vibromax female test hose to JCB male test point Description Qty a/r B a/r Note: In order to use JCB test hoses and gauges on JCB Vibromax machines (and where applicable, other manufacturers machines fitted with M16 X2mm test points) a special adaptor A is required. For JCB Vibromax dealers or customers that already have JCB Vibromax compatible test hoses a `special adaptor' B (not shown) will be required to connect to JCB test points 1-17 1-17 9813/0700

Section 1 - General Information Service Tools Tool Detail Reference Page left intentionally blank 1-18 1-18 9813/0700

Section 1 - General Information Torque Settings Zinc Plated Fasteners and Dacromet Fasteners Torque Settings Zinc Plated Fasteners and Dacromet Fasteners T11-002 Introduction Bolts and Screws Some external fasteners on JCB machines are manufactured using an improved type of corrosion resistant finish. This type of finish is called Dacromet and replaces the original Zinc and Yellow Plating used on earlier machines. Use the following torque setting tables only where no torque setting is specified in the text. Note: Dacromet fasteners are lubricated as part of the plating process, do not lubricate. The two types of fasteners can be readily identified by colour and part number suffix. K ( T T 1-19). Torque settings are given for the following conditions: K Table 1. Fastener Types Condition 1 Table 1. Fastener Types Colour Un-lubricated fasteners Zinc fasteners Yellow plated fasteners Fastener Type Zinc and Yellow Dacromet Part No. Suffix Golden finish 'Z' (e.g. 1315/3712Z) Condition 2 Mottled silver finish 'D' (e.g. 1315/3712D) Zinc flake (Dacromet) fasteners Lubricated zinc and yellow plated fasteners Where there is a natural lubrication. For example, cast iron components Note: As the Dacromet fasteners have a lower torque setting than the Zinc and Yellow fasteners, the torque figures used must be relevant to the type of fastener. Note: A Dacromet bolt should not be used in conjunction with a Zinc or Yellow plated nut, as this could change the torque characteristics of the torque setting further. For the same reason, a Dacromet nut should not be used with a Zinc or Yellow plated bolt. Verbus Ripp Bolts Note: All bolts used on JCB machines are high tensile and must not be replaced by bolts of a lesser tensile specification. Fig 36. Note: Dacromet bolts, due to their high corrosion resistance are used in areas where rust could occur. Dacromet bolts are only used for external applications. They are not used in applications such as gearbox or engine joint seams or internal applications. Torque settings for these bolts are determined by the application. Refer to the relevant procedure for the required settings. 1-19 1-19 9813/0700

Section 1 - General Information Torque Settings Zinc Plated Fasteners and Dacromet Fasteners Table 2. Torque Settings - UNF Grade 'S' Fasteners Hexagon (A/F) in. Nm 7/16 11.2 1/2 22.3 9/16 40.0 5/8 64.0 3/4 98.00 13/16 140.0 15/16 196.0 1 1/8 343.0 1 15/16 547.0 1 1/2 814.0 1 7/8 1181.0 2 1/4 1646.0 Bolt Size Condition 1 kgf m 1.1 2.3 4.1 6.5 10.0 14.3 20.0 35.0 55.8 83.0 120.4 167.8 Condition 2 kgf m 1.0 2.0 3.7 5.8 9.0 12.8 18.0 31.5 50.2 74.6 108.4 151.0 in. 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8 1 1/4 mm 6.3 7.9 9.5 11.1 12.7 14.3 15.9 19.0 22.2 25.4 31.7 38.1 lbf ft 8.3 16.4 29.5 47.2 72.3 103.2 144.6 253.0 403.4 600.4 871.1 1214.0 Nm 10.0 20.0 36.0 57.0 88.0 126.0 177.0 309.0 492.0 732.0 1063.0 1481.0 lbf ft 7.4 14.7 26.5 42.0 64.9 92.9 130.5 227.9 362.9 539.9 784.0 1092.3 Table 3. Torque Settings - Metric Grade 8.8 Fasteners Hexagon (A/F) Bolt Size Condition 1 Condition 2 ISO Metric Thread M5 M6 M8 M10 M12 M16 M20 M24 M30 M36 mm 5 6 8 10 12 16 20 24 30 36 mm 8 10 13 17 19 24 30 36 46 55 Nm 5.8 9.9 24.0 47.0 83.0 205.0 400.0 690.0 1372.0 2399.0 kgf m 0.6 1.0 2.4 4.8 8.5 20.9 40.8 70.4 139.9 244.6 lbf ft 4.3 7.3 17.7 34.7 61.2 151.2 295.0 508.9 1011.9 1769.4 Nm 5.2 9.0 22.0 43.0 74.0 184.0 360.0 621.0 1235.0 2159.0 kgf m 0.5 0.9 2.2 4.4 7.5 18.8 36.7 63.3 125.9 220.0 lbf ft 3.8 6.6 16.2 31.7 54.6 135.7 265.5 458.0 910.9 1592.4 1-20 1-20 9813/0700

Section 1 - General Information Torque Settings Zinc Plated Fasteners and Dacromet Fasteners Table 4. Metric Grade 10.9 Fasteners Hexagon (A/F) Bolt Size Condition 1 Condition 2 ISO Metric Thread M5 M6 M8 M10 M12 M16 M20 M24 M30 M36 mm 5 6 8 10 12 16 20 24 30 36 mm 8 10 13 17 19 24 30 36 46 55 Nm 8.1 13.9 34.0 67.0 116.0 288.0 562.0 971.0 1930.0 3374.0 kgf m 0.8 1.4 3.5 6.8 11.8 29.4 57.3 99.0 196.8 344.0 lbf ft 6.0 10.2 25.0 49.4 85.5 212.4 414.5 716.9 1423.5 2488.5 Nm 7.3 12.5 30.0 60.0 104.0 259.0 506.0 874.0 1737.0 3036.0 kgf m 0.7 1.3 3.0 6.1 10.6 26.4 51.6 89.1 177.1 309.6 lbf ft 5.4 9.2 22.1 44.2 76.7 191.0 373.2 644.6 1281.1 2239.2 Table 5. Metric Grade 12.9 Fasteners Hexagon (A/F) Bolt Size Condition 1 Condition 2 ISO Metric Thread M5 M6 M8 M10 M12 M16 M20 M24 M30 M36 mm 5 6 8 10 12 16 20 24 30 36 mm 8 10 13 17 19 24 30 36 46 55 Nm 9.8 16.6 40.0 80.0 139.0 345.0 674.0 1165.0 2316.0 4049.0 kgf m 1.0 1.7 4.1 8.1 14.2 35.2 68.7 118.8 236.2 412.9 lbf ft 7.2 12.2 29.5 59.0 102.5 254.4 497.1 859.2 1708.2 2986.4 Nm 8.8 15.0 36.0 72.0 125.0 311.0 607.0 1048.0 2084.0 3644.0 kgf m 0.9 1.5 3.7 7.3 12.7 31.7 61.9 106.9 212.5 371.6 lbf ft 6.5 11.1 26.5 53.1 92.2 229.4 447.7 773.0 1537.1 2687.7 1-21 1-21 9813/0700

Section 1 - General Information Torque Settings Zinc Plated Fasteners and Dacromet Fasteners Table 6. Torque Settings - Rivet Nut Bolts/Screws Bolt Size ISO Metric Thread mm M3 3 M4 4 M5 5 M6 6 M8 8 M10 10 M12 12 Nm 1.2 3.0 6.0 10.0 24.0 48.0 82.0 kgf m 0.1 0.3 0.6 1.0 2.5 4.9 8.4 lbf ft 0.9 2.0 4.5 7.5 18.0 35.5 60.5 Table 7. Torque Settings - Internal Hexagon Headed Cap Screws (Zinc) Bolt Size ISO Metric Thread M3 2.0 M4 6.0 M5 11.0 M6 19.0 M8 46.0 M10 91.0 M12 159.0 M16 395.0 M18 550.0 M20 770.0 M24 1332.0 Nm kgf m 0.2 0.6 1.1 1.9 4.7 9.3 16.2 40.0 56.0 79.0 136.0 lbf ft 1.5 4.5 8.0 14.0 34.0 67.0 117.0 292.0 406.0 568.0 983.0 1-22 1-22 9813/0700

Section 1 - General Information Torque Settings Vibromax Specific Torque Settings Vibromax Specific Torque Settings Where no special torque data is specified, the following standard torque figures should be applied. Table 8. Standard Torque Specifications +/- 10% GRADE 8.8 Nm lb/ft 5.5 4 9 6.6 22.5 16.5 44 32 77.5 57 120 88 190 140 260 192 370 273 500 369 640 471 950 702 1300 955 GRADE 10.9 Nm 7.5 12.5 31.5 62 110 170 265 365 520 700 900 1350 1800 GRADE 12.9 Nm 9 15 36 75 130 210 320 435 620 840 1080 1620 2160 SIZE 5mm 6mm 8mm 10mm 12mm 14mm 16mm 18mm 20mm 22mm 24mm 27mm 30mm lb/ft 5.5 9.2 23 45 81 125 195 269 383 516 665 996 1328 lb/ft 6.6 11 26.5 55 95 155 236 320 457 619 796 1195 1593 Table 9. Nuts for Tubes and Hoses DIAMETER AND PITCH 16mm X 1.5 18mm X 1.5 20mmX 1.45 24mm X 1.5 Nm 20 35 45 60 lb/ft 14.5 26 33.2 44 1-23 1-23 9813/0700

Section 1 - General Information Torque Settings Vibromax Specific Torque Settings Table 10. Fittings, Connections and Plugs DIAMETER AND PITCH 10mm X 1.5 12mm X 1.5 14mm X 1.5 16mm X 1.5 18mm X 1.5 22mm X 1.5 27mm X 1.5 33mm X 1.5 42mm X 1.5 Nm 20 35 45 60 70 100 200 280 380 lb/ft 14.5 26 33.2 44 51 73 147 207 281 Table 11. Flanges Nm 28 55 90 145 230 DIAMETER AND PITCH 8mm X 1.5 10mm X 1.5 12mm X 1.75 14mm X 2 15mm X 2 lb/ft 21 41 67 107 170 1-24 1-24 9813/0700

Section 1 - General Information Torque Settings Hydraulic Connections Hydraulic Connections T11-003 'O' Ring Face Seal System Adaptors Screwed into Valve Blocks Adaptor screwed into valve blocks, seal onto an 'O' ring which is compressed into a 45 seat machined into the face of the tapped port. Table 12. Torque Settings - BSP Adaptors BSP Adaptor Size in. mm 1/4 19.0 3/8 22.0 1/2 27.0 5/8 30.0 3/4 32.0 1 38.0 1 1/4 50.0 Hexagon (A/F) Nm 18.0 31.0 49.0 60.0 81.0 129.0 206.0 kgf m 1.8 3.2 5.0 6.1 8.2 13.1 21.0 lbf ft 13.0 23.0 36.0 44.0 60.0 95.0 152.0 Table 13. Torque Settings - SAE Connections Hexagon (A/F) mm 7/16 - 20 15.9 9/16 - 18 19.1 3/4 - 16 22.2 7/8 - 14 27.0 1 1/16 - 12 31.8 1 5/16 - 12 38.1 1 5/8 47.6 SAE Tube Size 4 6 8 10 12 16 20 SAE Port Thread Size Nm kgf m 2.0 - 2.8 4.7 - 5.5 9.7 - 10.7 13.2 - 14.3 19.4 - 21.4 29.6 - 31.6 28.5 - 38.7 lbf ft 20.0 - 28.0 46.0 - 54.0 95.0 - 105.0 130.0 - 140.0 190.0 - 210.0 290.0 - 310.0 280.0 - 380.0 16.5 - 18.5 34.0 - 40.0 69.0 - 77.0 96.0 - 104.0 141.0 - 155.0 216.0 - 230.0 210.0 - 280.0 1-25 1-25 9813/0700

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Section 1 - General Information Torque Settings Hydraulic Connections Hoses Screwed into Adaptors Fig 37. Hoses 37-B screwed into adaptors 37-A seal onto an `O' ring 37-C which is compressed into a 45 seat machined into the face of the adaptor port. Note: Dimension 37-D will vary depending upon the torque applied. Table 14. BSP Hose - Torque Settings Hexagon (A/F) mm 14.0 14.0 - 16.00 19.0 24.0 - 27.0 22.0 33.0 - 40.0 27.0 44.0 - 50.0 30.0 58.0 - 65.0 32.0 84.0 - 92.0 38.0 115.0 - 126.0 50.0 189.0 - 200.0 55.0 244.0 - 260.0 BSP Hose Size in. 1/8 1/4 3/8 1/2 5/8 3/4 1 1 1/4 1 1/2 Nm kgf m 1.4 - 1.6 2.4 - 2.7 3.4 - 4.1 4.5 - 5.1 5.9 - 6.6 8.6 - 9.4 11.7 - 12.8 19.3 - 20.4 24.9 - 26.5 lbf ft 10.3 - 11.8 17.7 - 19.9 24.3 - 29.5 32.4 - 36.9 42.8 - 47.9 61.9 - 67.8 84.8 - 92.9 139.4 - 147.5 180.0 - 191.8 1-26 1-26 9813/0700

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com