JCB 515-40 TELESCOPIC HANDLER Service Repair Manual Instant Download (515-40 from SN 1627500 to 1769999)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

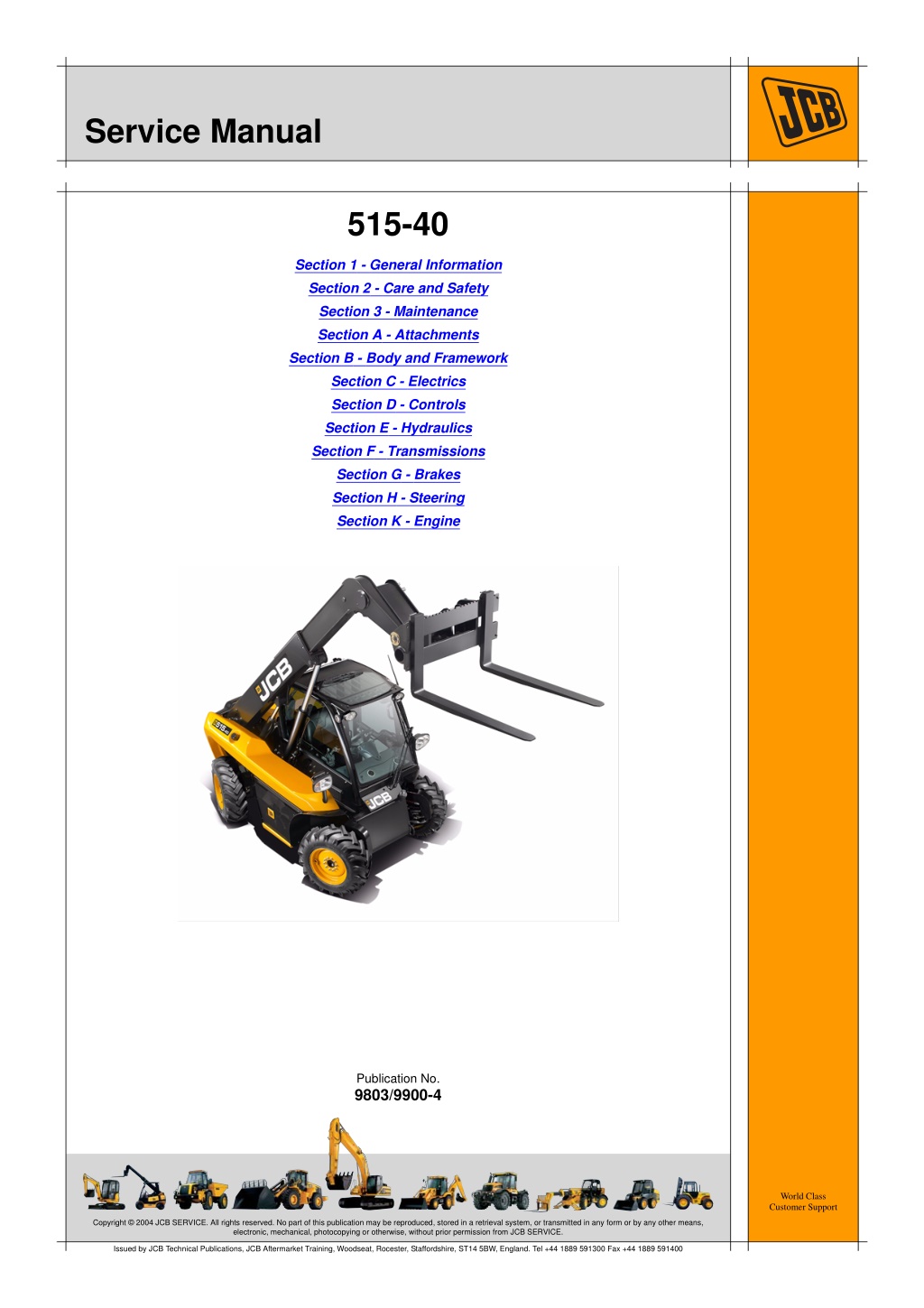

Service Manual 515-40 Section 1 - General Information Section 2 - Care and Safety Section 3 - Maintenance Section A - Attachments Section B - Body and Framework Section C - Electrics Section D - Controls Section E - Hydraulics Section F - Transmissions Section G - Brakes Section H - Steering Section K - Engine Publication No. 9803/9900-4 World Class Customer Support Copyright 2004 JCB SERVICE. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB SERVICE. Issued by JCB Technical Publications, JCB Aftermarket Training, Woodseat, Rocester, Staffordshire, ST14 5BW, England. Tel +44 1889 591300 Fax +44 1889 591400

Section 1 General Information Service Manual - 515-40 Section 1 - General Information Section 2 - Care and Safety Section 3 - Maintenance Section A - Attachments Section B - Body and Framework Section C - Electrics Section D - Controls Section E - Hydraulics Section F - Transmissions Section G - Brakes Section H - Steering Section K - Engine Publication No. 9803/9900-4 World Class Customer Support Copyright 2004 JCB SERVICE. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB SERVICE. Issued by JCB Technical Publications, JCB Aftermarket Training, Woodseat, Rocester, Staffordshire, ST14 5BW, England. Tel +44 1889 591300 Fax +44 1889 591400

Section 1 - General Information Contents Introduction About This Publication ............................................................................... 1-1 Identifying Your Machine ........................................................................... 1-3 Moving a Disabled Machine ...................................................................... 1-8 Transporting the Machine .......................................................................... 1-9 Lifting the Machine .................................................................................. 1-11 Page No. Standard Torque Settings Zinc Plated Fasteners and Dacromet Fasteners ..................................... 1-13 Hydraulic Connections ............................................................................. 1-17 Service Tools Numerical List .......................................................................................... 1-21 Tool Detail Reference .............................................................................. 1-23 Service Consumables Sealing and Retaining Compounds ......................................................... 1-39 Terms and Definitions Colour Coding .......................................................................................... 1-41 1-i 1-i

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Section 1 - General Information Introduction About This Publication Machine Model and Serial Number Finally, please remember above all else safety must come first! This manual provides information for the following model(s) in the JCB machine range: Section Numbering T11-005 515-40 from SN 1627500 to 1769999 The manual is compiled in sections, the first three are numbered and contain information as follows: Using the Service Manual General Information - includes torque settings and service tools. Care and Safety - includes warnings and cautions pertinent to aspects of workshop procedures etc. Maintenance - includes service schedules and recommended lubricants for all the machine. 1 T11-004 This publication is designed for the benefit of JCB Distributor Service Engineers who are receiving, or have received, training by JCB Technical Training Department. 2 3 These personnel should have a sound knowledge of workshop practice, safety procedures, and general techniques associated with the maintenance and repair of hydraulic earthmoving equipment. The remaining sections are alphabetically coded and deal with Dismantling, Overhaul etc. of specific components, for example: The illustrations in this publication are for guidance only. Where the machines differ, the text and/or the illustration will specify. Attachments Body and Framework, etc. A B General warnings in Section 2 are repeated throughout the manual, as well as specific warnings. Read all safety statements regularly, so you do not forget them. Section contents, technical data, circuit descriptions, operation descriptions etc. are inserted at the beginning of each alphabetically coded section. Renewal of oil seals, gaskets, etc., and any component showing obvious signs of wear or damage is expected as a matter of course. It is expected that components will be cleaned and lubricated where appropriate, and that any opened hose or pipe connections will be blanked to prevent excessive loss of hydraulic fluid and ingress of dirt. Where a torque setting is given as a single figure it may be varied by plus or minus 3%. Torque figures indicated are for dry threads, hence for lubricated threads may be reduced by one third. The manufacturer's policy is one of continuous improvement. The right to change the specification of the machine without notice is reserved. No responsibility will be accepted for discrepancies which may occur between specifications of the machine and the descriptions contained in this publication. 1-1 1-1 9803/9900-4

Section 1 - General Information Introduction About This Publication Left Side, Right Side In this manual, 'left' A and 'right' B mean your left and right when you are seated correctly in the machine. 447200-2 Fig 1. Cross References T1-004_2 In this publication, page cross references are made by presenting the subject title printed in bold, italic and underlined. It is preceeded by the 'go to' symbol. The number of the page upon which the subject begins, is indicated within the brackets. For example: K References ( T T 1-2). K Cross 1-2 1-2 9803/9900-4

Section 1 - General Information Introduction Identifying Your Machine Identifying Your Machine Machine Identification Plate Typical Product Identification Number The PIN, weight, engine power, year of manufacture and serial number of the machine are stamped on the identification plate. Your machine has an identification plate mounted as shown. The serial numbers of the machine and its major units are stamped on the plate. J C B 5 1 5 4 0 L 9 1 6 2 7 5 0 1 3 2 1 Note: The machine model and build specification is indicated by the PIN. Refer to Typical Product Identification Number (PIN). 4 The serial number of each major unit is also stamped on the unit itself. If a major unit is replaced by a new one, the serial number on the identification plate will be wrong. Either stamp the new number of the unit on the identification plate, or simply stamp out the old number. This will prevent the wrong unit number being quoted when replacement parts are ordered. World Manufacturer Identification (3 Digits) 1 Machine Model (5 Digits) 2 Randomly Generated Check Letter (1 Digit) 3 Year of Manufacture (1 Digit) 4 The machine and engine serial numbers can help identify exactly the type of equipment you have. 9 = 2009 B = 2011 A = 2010 C = 2012 Machine Serial Number (7 Digits) 5 Each machine has a unique serial number. 0123 POWER OUTLET 12V F F 1 0 R R 817-18435-2 C091000 Fig 3. Fig 2. Machine identification plate 1-3 1-3 9803/9900-4

Section 1 - General Information Introduction Identifying Your Machine The machine PIN is also stamped onto the fuel tank as at A and onto the chassis behind the fan assembly as shown at B. C093310 Fig 4. 1-4 1-4 9803/9900-4

Section 1 - General Information Introduction Identifying Your Machine Component Identification Plates Typical Engine Identification Number The engine data label is located on the top of the engine. If the engine is replaced by a new one, the data plate serial number will be wrong. Either stamp the new number on the plate or stamp out the old one. This will prevent the wrong number being quoted when you order replacement parts. a D b c L d 04 e 2009 9999999 Type (D = Diesel) a Series (2009) b Cylinder layout (L = In series) c C089980 Fig 6. Number of cylinders (04 = 4 Cylinder) d Typical Engine Identification Number - Deutz Engine Serial Number (7 Digits) e If the engine is replaced by a new one, the data plate serial number will be wrong. Either stamp the new number on the plate or stamp out the old one. This will prevent the wrong number being quoted when you order replacement parts. a b c J d e 2 AB 50316 000001 Engine Type (AB= 4 cylinder turbo) a Engine Parts List b C089970-C3 Country of Manufacture c Fig 5. Engine Serial Number d Note: The engine serial number F is also stamped on the engine. K K Fig 6. ( T T 1-5). Year of Manufacture e 1-5 1-5 9803/9900-4

Section 1 - General Information Introduction Identifying Your Machine Kohler Engine EPA Family ID 3 Tune-up Specifications: Injection Timing 4 Typical Engine Identification Number Tune-up Specifications: Injection Opening Pressure 5 The engine data label is located on the top of the engine. If the engine is replaced by a new one, the data plate serial number will be wrong. PM 6 Fuel Type 7 Either stamp the new number on the plate or stamp out the old one. This will prevent the wrong number being quoted when you order replacement parts. Engine Model a Engine Serial Number b EU Approval Code c 1 2 3 6 Specification Number d RPM e 7 4 5 a e C089970-C2 Fig 8. d b c C089970-C10 Fig 7. Emission Control Information The data plate which shows the EPA regulations is on the rocker arm cover. Power Category 1 Engine Displacement 2 1-6 1-6 9803/9900-4

Section 1 - General Information Introduction Identifying Your Machine FOPS Data Plate ROPS Data Plate !MWARNING !MWARNING Do not use the machine if the falling objects protection level provided by the structure is not sufficient for the application. Falling objects can cause serious injury. You could be killed or seriously injured if you operate a machine with a damaged or missing ROPS/FOPS. If the Roll Over Protection Structure (ROPS)/Falling Objects Protection Structure (FOPS) has been in an accident, do not use the machine until the structure has been renewed. Modifications and repairs that are not approved by the manufacturer may be dangerous and will invalidate the ROPS/FOPS certification. 8-2-8-17 If the machine is used in any application where there is a risk of falling objects then a falling-objects protective structure (FOPS) must be installed. For further information contact your JCB Dealer INT-2-1-9_6 !MWARNING The falling objects protection structure (FOPS) is fitted with a dataplate. The dataplate indicates what level protection the structure provides. Seat Belts The ROPS/FOPS is designed to give you protection in an accident. If you do not wear your seat belt, you could be thrown out of the machine and crushed. You must wear a seat belt when using the machine. Fasten the seat belt before starting the engine. There are two levels of FOPS: Level I Impact Protection - impact strength for protection from small falling objects (e.g. bricks, small concrete blocks, hand tools) encountered in operations such as landscaping and other construction site services. Level II Impact Protection - impact strength for protection from heavy falling objects (e.g. trees, rocks) for machines involved in site clearing, overhead demolition or forestry. 0153 highway maintenance, The machine is built to the ROPS standard and has a data plate attached to the frame. K K Fig 10. ( T T 1-7). For an example of the ROPS data plate, refer to K K Fig 10. ( T T 1-7). For an example of the FOPS data plate, refer to K K Fig 9. ( T T 1-7). FOPS: COMPLIES TO EN ISO 3449:2008 LEVEL 1 ROPS: COMPLIES TO EN ISO 3471:2008 J.C.B. CAB SYSTEMS LAKESIDE WORKS ROCESTER UTTOXETER, STAFFS ST14 5JP ENGLAND 515-40 MAXIMUM UNLADEN MASS 5000kg. FOPS: COMPLIES TO EN ISO 3449:2008 LEVEL 1 ROPS: COMPLIES TO EN ISO 3471:2008 J.C.B. CAB SYSTEMS LAKESIDE WORKS ROCESTER UTTOXETER, STAFFS ST14 5JP ENGLAND 515-40 CAB PART No: 332/W1466 YEAR: SERIAL No: 333/P2846 MAXIMUM UNLADEN MASS 5000kg. C090690 CAB PART No: 332/W1466 YEAR: Fig 10. SERIAL No: 333/P2846 C090690 Fig 9. 1-7 1-7 9803/9900-4

Section 1 - General Information Introduction Moving a Disabled Machine Moving a Disabled Machine Important: This procedure should only be carried out be a qualified engineer. If you have any queries concerning this procedure, consult your local JCB Distributor. Open the bypass valve, as follows: 4 Remove the operators seat base to get access to the transmission pump. Refer to Maintenance, Operators Seat Base. a !MCAUTION Unscrew plug A by three full turns. b The transmission will be damaged, if the machine is moved unless the transmission pump is prepared for towing. Remove the wheel chocks from each wheel and tow the machine to a place of repair at a maximum speed of 6 mph (10 kph). Tow the machine the minimum distance necessary (maximum one mile). When towing is complete, place chocks both sides of each wheel. 5 4-2-5-6 !MCAUTION Recovery Hitch The counterweight is fitted with a recovery hitch which must not be used for towing. Tighten the plug A to close the bypass valve. 6 2-1-1-11_2 Remove the tow bar and wheel blocks. 7 !MCAUTION Replace the operator seat base. 8 Towing a machine too far or too fast can damage the transmission. Do not tow the machine further than one mile. Use a trailer for greater distances. When towing do not travel faster than 6 mph (10 km/h). Use a rigid draw-bar. If a towing chain must be used, then use two towing vehicles. One towing vehicle should be coupled to the front of the disabled machine. The other towing vehicle should be coupled to the rear of the disabled machine, to provide braking power. The towing vehicle(s) must have enough pulling and braking power to move and stop the machine. 2-2-7-34-1 Using suitable lifting equipment, remove any payload from the machine. 1 Attach a rigid tow bar between a suitable connection point on the machine and the towing vehicle. 2 C091480 Fig 11. Place blocks both sides of each wheel on the disabled machine. 3 Important: If the machine is to be towed the transmission bypass valve must be adjusted as shown below. The machine should only be towed the minimum distance required to load it onto a transporter. The transporter should be positioned as close as possible to the machine. 1-8 1-8 9803/9900-4

Section 1 - General Information Introduction Transporting the Machine Transporting the Machine !MWARNING Switch off the engine. g Put blocks at the front and rear of all four tyres. h The safe transit of the load is the responsibility of the transport contractor and driver. Any machine, attachments or parts that may move during transit must be adequately secured. Secure the cab. i Cover the exhaust pipe. j 5-2-5-9 Loading a disabled machine onto the trailer: Important: Use only the tie down anchor points specified. Align the trailer with the rear of the machine. a Note: Before transporting the machine make sure you will be obeying the rules and laws of all the areas that the machine will be carried through. Note: The trailer must be equipped with a winch to pull the machine aboard. Make sure that the transporting vehicle is suitable. See Static Dimensions (SPECIFICATIONS section) for the dimensions of your machine. Make sure the ramps are correctly in place and secure. b !MWARNING Connect the winch cable onto the recovery hitch on the back of the machine. c Before moving the machine onto the trailer, make sure that the trailer and ramp are free from oil, grease and ice. Remove oil, grease and ice from the machine tyres. Make sure the machine will not foul on the ramp angle. See Static Dimensions in SPECIFICATION section for the minimum ground clearance of your machine. K Moving a Prepare the machine for recovery. K Disabled Machine ( T d T 1-8) Operate the winch and pull the machine onto the trailer until the shovel/attachment is well inside the back end of the trailer. e 2-2-7-5_1 Engage the park brake. f Place blocks at the front and rear of the trailer wheels. 1 Put blocks at the front and rear of all four tyres. g Move the machine onto the trailer. 2 Lower the carriage onto the trailer. h Loading a serviceable machine onto the trailer: Check that the overall height of the load is within regulations. Adjust if necessary. i Make sure the ramps are correctly in place and secure. a Secure the cab. j Set the boom. b Cover the exhaust pipe. k Carefully drive the machine onto the trailer. c Anchor the machine to the trailer with chains. The anchor points are shown on the illustration. 3 Engage the park brake and set the drive to neutral. d Measure the maximum height of the machine from the ground. Make sure the truck driver knows the clearance height before he drives away. 4 Lower the carriage onto the trailer. e Check that the overall height of the load is within regulations. Adjust if necessary. f 1-9 1-9 9803/9900-4

Section 1 - General Information Introduction Transporting the Machine T043110-C2 Fig 12. Hooks can be used on the anchor points 1-10 1-10 9803/9900-4

Section 1 - General Information Introduction Lifting the Machine Lifting the Machine Introduction Do not use the anchor points to lift the machine. If the anchor points are used, the machine will not lift evenly and become unstable. B A The lifting-eyes in the top surface of the counterweight are for the removal and installation of the counterweight only. The lifting-eyes can not support the weight of the machine. To safely lift the machine, the Lifting Point Option (333/ R3798) must be installed, refer to your JCB Dealer. Preparing the Machine Stop the machine on level, solid ground. 1 Engage the park brake and set the drive to neutral. 2 333-R3798 Fig 13. Retract the boom. 3 !MWARNING Lower the boom fully, then lift it slightly. 4 Lifting Equipment You can be injured if you use incorrect or faulty lifting equipment. You must identify the weight of the item to be lifted then choose lifting equipment that is strong enough and suitable for the job. Make sure that lifting equipment is in good condition and complies with all local regulations. Tilt the carriage back to keep the heel of the forks 300mm (12in.) above the ground. 5 Switch off the engine and remove the starter key. 6 Isolate the battery. 7 INT-1-3-7_2 Remove all loose equipment. 8 Attach the lifting equipment to the D-shackles. 10 Attach the D-shackles: 9 Install a spreader-frame to prevent damage to the machine. 11 Attach a D-shackle A to the front sling-point. The front sling-point is a permanent fixture, which is welded to the steel fuel tank. The fuel tank is part of the chassis, which gives the sling-point extra strength. Attach a D-shackle B to the two rear sling-points. The two rear sling-points are attached to the chassis with M16 bolts. Note: The D-shackles each have a safe working load of five tonnes. 1-11 1-11 9803/9900-4

Section 1 - General Information Introduction Lifting the Machine Lifting the Machine !MDANGER Do not stand underneath the raised load during the lowering procedure. Stand clear and to one side until the load has been safely lowered. Make sure that the area is clear of other people before lowering the load. If you do not follow these precautions you or others could be killed or seriously injured. 2-3-5-3 Make sure that the lifting-eye is directly above the centre of the machine. 1 Lift the machine. 2 Make sure that the lifting equipment does not catch the machine. 1-12 1-12 9803/9900-4

Section 2 Care and Safety Service Manual - 515-40 Section 1 - General Information Section 2 - Care and Safety Section 3 - Maintenance Section A - Attachments Section B - Body and Framework Section C - Electrics Section D - Controls Section E - Hydraulics Section F - Transmissions Section G - Brakes Section H - Steering Section K - Engine Publication No. 9803/9900-2 World Class Customer Support Copyright 2004 JCB SERVICE. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB SERVICE. Issued by JCB Technical Publications, JCB Aftermarket Training, Woodseat, Rocester, Staffordshire, ST14 5BW, England. Tel +44 1889 591300 Fax +44 1889 591400

Section 2 - Care and Safety Contents Safety Notices Important Information ................................................................................ 2-1 Safety Check List ....................................................................................... 2-2 Safety Labels ........................................................................................... 2-13 Page No. 2-i 2-i

Section 2 - Care and Safety Safety Notices Important Information T1-042 The Operator Manual Safety Warnings !MWARNING This safety alert system identifies important safety messages in this manual. When you see this symbol, be alert, your safety is involved, carefuly read the message that follows, and inform other operators. You and others can be killed or seriously injured if you operate or maintain the machine without first studying the Operator Manual. You must understand and follow the instructions in the Operator Manual. If you do not understand anything, ask your employer or JCB dealer to explain it. In this publication and on the machine, there are safety notices. Each notice starts with a signal word. The signal word meanings are given below. INT-1-4-2 Do not operate the machine without an Operator Manual, or if there is anything on the machine you do not understand. !MDANGER Denotes an extreme hazard exists. If proper precautions are not taken, it is highly probable that the operator (or others) could be killed or seriously injured. Treat the Operator Manual as part of the machine. Keep it clean and in good condition. Replace the Operator Manual immediately if it is lost, damaged or becomes unreadable. INT-1-2-1 !MWARNING Denotes a hazard exists. If proper precautions are not taken, the operator (or others) could be killed or seriously injured. INT-1-2-2 !MCAUTION Denotes a reminder of safety practices. Failure to follow these safety practices could result in injury to the operator (or others) and possible damage to the machine. INT-1-2-3 2-1 2-1 9803/9900-2

Section 2 - Care and Safety Safety Notices Safety Check List Safety Check List P5-1010_3 Safety - Yours and Others General Safety INT-1-3-1_3 T1-043 !MWARNING All machinery can be hazardous. When a machine is correctly operated and properly maintained, it is a safe machine to work with. But when it is carelessly operated or poorly maintained it can become a danger to you (the operator) and others. To operate the machine safely you must know the machine and have the skill to use it. You must abide by all relevant laws, health and safety regulations that apply to the country you are operating in. The Operator Manual instructs you on the machine, its controls and its safe operation; it is not a training manual. If you are a new operator, get yourself trained in the skills of using a machine before trying to work with it. If you don't, you will not do your job well, and you will be a danger to yourself and others. In this manual and on the machine you will find warning messages. Read and understand them. They tell you of potential hazards and how to avoid them. If you do not fully understand the warning messages, ask your employer or JCB distributor to explain them. But safety is not just a matter of responding to the warnings. All the time you are working on or with the machine you must be thinking what hazards there might be and how to avoid them. INT-1-4-1 !MWARNING Care and Alertness Do not work with the machine until you are sure that you can control it. All the time you are working with or on the machine, take care and stay alert. Always be careful. Always be alert for hazards. Do not start any job until you are sure that you and those around you will be safe. INT-1-3-5 !MWARNING Clothing If you are unsure of anything, about the machine or the job, ask someone who knows. Do not assume anything. You can be injured if you do not wear the proper clothing. Loose clothing can get caught in the machinery. Wear protective clothing to suit the job. Examples of protective clothing are: a hard hat, safety shoes, safety glasses, a well fitting overall, ear- protectors and industrial gloves. Keep cuffs fastened. Do not wear a necktie or scarf. Keep long hair restrained. Remove rings, watches and personal jewellery. Remember BE CAREFUL BE ALERT BE SAFE INT-1-3-6_2 !MWARNING Alcohol and Drugs It is extremely dangerous to operate machinery when under the influence of alcohol or drugs. Do not consume alcoholic drinks or take drugs before or while operating the machine or attachments. Be aware of medicines which can cause drowsiness. INT-1-3-9_2 2-2 2-2 9803/9900-2

Section 2 - Care and Safety Safety Notices Safety Check List !MWARNING Feeling Unwell !MDANGER Lightning Do not attempt to operate the machine if you are feeling unwell. By doing so you could be a danger to yourself and those you work with. Lightning can kill you. Do not use the machine if there is lightning in your area. 5-1-1-2 8-1-2-4 !MWARNING !MWARNING Mobile Phones Machine Modifications This machine is manufactured in compliance with legislative and other requirements. It should not be altered in any way which could affect or invalidate any of these requirements. For advice consult your JCB Distributor. Switch off your mobile phone before entering an area with a potentially explosive atmosphere. Sparks in such an area could cause an explosion or fire resulting in death or serious injury. INT-1-3-10_2 Switch off and do not use your mobile phone when refuelling the machine. INT-3-3-9 !MWARNING Lifting Equipment You can be injured if you use incorrect or faulty lifting equipment. You must identify the weight of the item to be lifted then choose lifting equipment that is strong enough and suitable for the job. Make sure that lifting equipment is in good condition and complies with all local regulations. INT-1-3-7_2 !MWARNING Raised Equipment Never walk or work under raised equipment unless it is supported by a mechanical device. Equipment which is supported only by a hydraulic device can drop and injure you if the hydraulic system fails or if the control is operated (even with the engine stopped). Make sure that no-one goes near the machine while you install or remove the mechanical device. 13-2-3-7_3 !MWARNING Raised Machine NEVER position yourself or any part of your body under a raised machine which is not properly supported. If the machine moves unexpectedly you could become trapped and suffer serious injury or be killed. INT-3-3-7_1 2-3 2-3 9803/9900-2

Section 2 - Care and Safety Safety Notices Safety Check List !MWARNING Work Sites Operating Safety !MWARNING Machine Condition Work sites can be hazardous. Inspect the site before working on it. You could be killed or injured if the ground gives way under your machine or if piled material collapses onto it. Check for potholes and hidden debris, logs, ironwork etc. Any of these could cause you to lose control of your machine. Check for utilities such as electric cables (overhead and underground), gas and water pipes etc. Mark the positions of the underground cables and pipes. Make sure that you have enough clearance beneath overhead cables and structures. A defective machine can injure you or others. Do not operate a machine which is defective or has missing parts. Make sure the maintenance procedures in this manual are completed before using the machine. INT-2-1-2_2 !MWARNING Machine Limits INT-2-2-1_2 Operating the machine beyond its design limits can damage the machine, it can also be dangerous. Do not operate the machine outside its limits. Do not try to upgrade the machine performance with unapproved modifications. !MWARNING Communications Bad communications can cause accidents. Keep people around you informed of what you will be doing. If you will be working with other people, make sure any hand signals that may be used are understood by everybody. Work sites can be noisy, do not rely on spoken commands. INT-2-1-4 !MWARNING Engine/Steering Failure If the engine or steering fails, stop the machine as quickly as possible. Do not operate the machine until the fault has been corrected. INT-2-2-3 !MWARNING INT-2-1-5 Parking !MWARNING An incorrectly parked machine can move without an operator. Follow the instructions in the Operator Manual to park the machine correctly. Exhaust Gases Breathing the machine exhaust gases can harm and possibly kill you. Do not operate the machine in closed spaces without making sure there is good ventilation. If possible, fit an exhaust extension. If you begin to feel drowsy, stop the machine at once and get into fresh air. INT-2-2-4_2 !MWARNING Banks and Trenches Banked material and trenches can collapse. Do not work or drive too close to banks and trenches where there is danger of collapse. INT-2-1-10_2 INT-2-2-5 !MWARNING Safety Barriers Unguarded machines in public places can be dangerous. In public places, or where your visibility is reduced, place barriers around the work area to keep people away. INT-2-2-8 2-4 2-4 9803/9900-2

Section 2 - Care and Safety Safety Notices Safety Check List !MDANGER Sparks !MWARNING Keep the machine controls clean and dry. Your hands and feet could slide off slippery controls. If that happens you could lose control of the machine. Explosions and fire can be caused by sparks from the exhaust or the electrical system. Do not use the machine in closed areas where there is flammable material, vapour or dust. 2-2-3-6 !MWARNING INT-2-2-10 !MWARNING Electrical Power Cables You could be electrocuted or badly burned if you get the machine or its attachments too close to electrical power cables. Hazardous Atmospheres This machine is designed for use in normal out door atmospheric conditions. It should not be used in an enclosed area without adequate ventilation. Do not use the machine in atmosphere, i.e. combustible vapours, gas or dust, without first consulting your JCB Distributor. You are strongly advised to make sure that the safety arrangements on site comply with the local laws and regulations concerning work near electric power lines. a potentially explosive Before you start using the machine, check with your electricity supplier if there are any buried power cables on the site. INT-2-1-14 !MCAUTION There is a minimum clearance required for working beneath overhead power cables. You must obtain details from your local electricity supplier. Regulations Obey all laws, work site and local regulations which affect you and your machine. 2-2-5-4 INT-1-3-3 !MCAUTION !MWARNING Practice If you have an attachment which is not covered in the Operator Manual do not install it, use it or remove it until you have obtained, read and understood the pertinent information. Install attachments only on the machines for which they were designed. You or others can be killed or seriously injured if you do unfamiliar operations without first practising them. Practise away from the work site on a clear area. Keep other people away. Do not perform new operations until you are sure you can do them safely. 5-5-1-1_2 INT-2-1-1 !MWARNING !MWARNING Use only the JCB approved attachments that are specified for your machine. Operating with non- specified attachments can overload the machine, causing possible damage and machine instability which could result in injury to yourself or others. Airborne particles of light combustible material such as straw, grass, wood shavings, etc. must not be allowed to accumulate within the engine compartment or in the propshaft guards (when fitted). Inspect these areas frequently and clean at the beginning of each work shift or more often if required. Before opening the engine cover, ensure that the top is clear of debris. The use of non-approved attachments could invalidate your warranty. 2-4-5-2_1 5-3-1-12_3 2-5 2-5 9803/9900-2

Section 2 - Care and Safety Safety Notices Safety Check List !MDANGER Working Platform !MCAUTION Fork Spacing Using the machine as a working platform is hazardous; you can fall off and be killed or injured. Never use the machine as a working platform. Loads can fall off incorrectly spaced forks. Always space the forks correctly for the load. Make sure the forks are completely under the load before lifting. 5-1-5-9 5-1-4-2 !MWARNING Machine Safety !MCAUTION One-Fork Lifting Stop work at once if a fault develops. Abnormal sounds and smells can be signs of trouble. Inspect and repair before resuming work. A load lifted on one fork can slip off. Never lift a load with one fork. 5-1-4-3 8-1-2-3 !MCAUTION !MWARNING Unloading Touching hot surfaces can burn skin. The engine and machine components will be hot after the unit has been running. Allow the engine and components to cool before servicing the unit. Never unload the forks by stopping the machine suddenly. Follow the procedures in the Operator Manual for unloading. 5-1-4-4_2 10-1-1-40 !MCAUTION !MWARNING Uneven Ground Travelling at High Speeds Loads stacked on uneven ground can topple. Never stack loads on uneven ground. Travelling at high speeds can cause accidents. Do not reverse in a high gear with full throttle. Always travel at a safe speed to suit working conditions. 5-1-4-5 !MWARNING Scaffolding INT-5-3-3 !MWARNING Overloaded scaffolding can collapse. Never load scaffolding beyond the regulation capacity. The engine has exposed rotating parts. Switch OFF the engine before working in the engine compartment. Do not use the machine with the engine cover open. 5-1-4-6 !MCAUTION 5-2-6-5 !MWARNING Overhead Clearance A raised boom can strike overhead objects. Always check for overhead clearance before raising the boom. You could be killed or seriously injured if you operate a machine with a damaged or missing ROPS/FOPS. If the Roll Over Protection Structure (ROPS)/Falling Objects Protection Structure (FOPS) has been in an accident, do not use the machine until the structure has been renewed. Modifications and repairs that are not approved by the manufacturer may be dangerous and will invalidate the ROPS/FOPS certification. 5-1-5-1 !MWARNING Boom/Machine Travel Operating the boom while you travel can cause accidents. You will not have total control of the machine. Never operate the boom when you travel. INT-2-1-9_6 5-1-5-2_2 2-6 2-6 9803/9900-2

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Section 2 - Care and Safety Safety Notices Safety Check List !MDANGER Forks/Working Platform !MWARNING Visibility Using the forks alone as a working platform is hazardous; you can fall off and be killed or injured. Never use the forks as a working platform. Accidents can be caused by working in poor visibility. Use your lights to improve visibility. Keep the road lights, windows and mirrors clean. 5-1-5-3 Do not operate the machine if you cannot see clearly. !MWARNING Forks/Turning 5-1-4-7 !MWARNING The forks project in front of the machine. Make sure there is enough clearance for the forks when making turns. Keep Your Hands and Feet Inside the Vehicle When using the machine, keep your hands and feet clear of moving parts. Keep your hands and feet within the operator compartment while the vehicle is in motion. 5-1-5-4_2 !MWARNING High Loads 13-1-1-17 !MWARNING Controls A high load can block your view and reduce the machine's stability. Travel with the load low to the ground. Travel slowly and with caution over rough, muddy or loose surfaces. You or others can be killed or seriously injured if you operate the control levers from outside the machine. Operate the control levers only when you are correctly seated. 5-1-3-2 !MWARNING Slopes 0179_2 !MCAUTION Passengers When transporting a load on a slope, drive slowly and keep the load uphill of the machine. This will increase stability. Passengers in or on the machine can cause accidents. Do not carry passengers. 5-1-4-1 !MWARNING Hillsides INT-2-2-2_1 !MWARNING Operating the machine on hillsides can be dangerous if proper precautions are not taken. Ground conditions can be changed by rain, snow, ice etc. Check the site carefully. Operate in first gear on hillsides, when applicable, keep all attachments low to the ground. Never coast down a hill with the engine off or the transmission in neutral. Fires If your machine is equipped with a fire extinguisher, make sure it is checked regularly. Keep it in the correct machine location until you need to use it. Do not use water to put out a machine fire, you could spread an oil fire or get a shock from an electrical fire. Use carbon dioxide, dry extinguishers. Contact your nearest fire department as quickly as possible. Firefighters should use self- contained breathing apparatus. INT-2-2-7 chemical or foam INT-3-2-7_2 2-7 2-7 9803/9900-2

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com