How Does a Holesaw Cutter Work?

Learn how a holesaw cutter operates to create clean, precise holes in different materials using its cylindrical design and sharp teeth, ideal for woodworking and metalworking projects.nVisit Us:- //sitcouae.co/hole-cutter-suppliers-in-dubai/n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

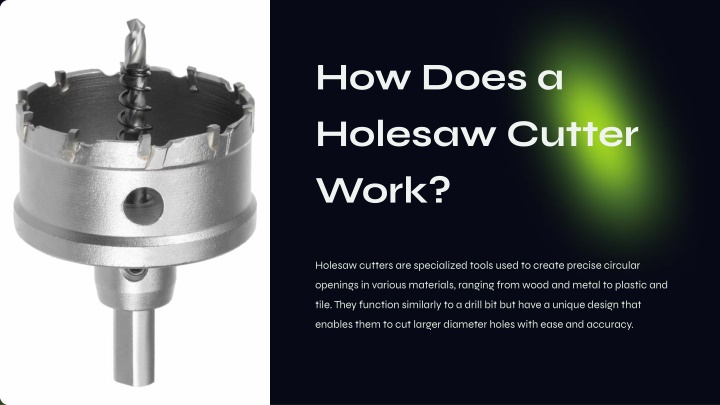

How Does a Holesaw Cutter Work? Holesaw cutters are specialized tools used to create precise circular openings in various materials, ranging from wood and metal to plastic and tile. They function similarly to a drill bit but have a unique design that enables them to cut larger diameter holes with ease and accuracy.

What is a Holesaw Cutter? Core Pilot Bit The core is the central portion of the holesaw The pilot bit is a small drill bit attached to the cutter and is typically made of hardened steel. core. Its purpose is to initiate the cutting It's designed to withstand the force of cutting process by drilling a starting hole in the and prevents the holesaw from bending or material. breaking during use. Cutting Teeth Arbor Cutting teeth are strategically positioned The arbor is a cylindrical shaft that connects along the outer edge of the holesaw. These the holesaw to the drill chuck. It allows the teeth are responsible for removing material as holesaw to be securely mounted and rotated the holesaw rotates, creating a clean and by the drill. precise hole.

The Anatomy of a Holesaw Cutter Core Pilot Bit 1 2 The core is the central portion of the The pilot bit is a small drill bit attached to holesaw cutter and is typically made of the core. Its purpose is to initiate the cutting hardened steel. It's designed to withstand process by drilling a starting hole in the the force of cutting and prevents the material. holesaw from bending or breaking during use. Cutting Teeth Arbor 3 4 Cutting teeth are strategically positioned The arbor is a cylindrical shaft that along the outer edge of the holesaw. These connects the holesaw to the drill chuck. It teeth are responsible for removing material allows the holesaw to be securely mounted as the holesaw rotates, creating a clean and rotated by the drill. and precise hole.

The Cutting Process Pilot Bit Drilling The pilot bit drills a Cutting Teeth Engaging The cutting teeth Hole Formation Removal of Material The holesaw The removed starting hole in the begin to remove continues to rotate, material is ejected material, providing a material as the enlarging the hole through the center guide for the holesaw rotates. until it reaches the of the holesaw, holesaw. desired diameter. leaving a clean and precise hole.

Choosing the Right Holesaw Cutter Material Type Diameter Cutting Depth The material being cut will The diameter of the hole The cutting depth refers to the influence the type of holesaw required will determine the maximum thickness of cutter required. size of the holesaw cutter material the holesaw can cut. Wood needed. Metal Plastic Tile

Applications of Holesaw Cutters Plumbing Cutting holes for pipes and faucets Electrical Creating openings for electrical outlets and wiring HVAC Drilling holes for ventilation and ductwork Woodworking Creating decorative patterns and holes in furniture and crafts

Thank You! Contact Us Saleh Ishaq Trading Co. LLC +971 4 224 7288 +971 55 875 1551 sitcotrd@gmail.com Visit us at:- https://sitcouae.co/