Exploring the Versatility of HDPE Bags: A Complete Handbook

In the realm of packaging, High-Density Polyethylene (HDPE) bags stand out as versatile, durable, and cost-effective solutions for various industries. These bags, known for their strength and reliability, find widespread use in sectors ranging from agriculture and construction to retail and transportation. In this comprehensive guide, we will delve into the world of HDPE bags, exploring their composition, manufacturing process by HDPE bag manufacturer, diverse applications, and environmental impact.n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

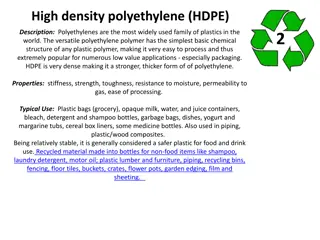

Exploring the Versatility of HDPE Bags: A Complete Handbook In the realm of packaging, High-Density Polyethylene (HDPE) bags stand out as versatile, durable, and cost-effective solutions for various industries. These bags, known for their strength and reliability, find widespread use in sectors ranging from agriculture and construction to retail and transportation. In this comprehensive guide, we will delve into the world of HDPE bags, exploring their composition, manufacturing process by HDPE bag manufacturer, diverse applications, and environmental impact. Understanding HDPE Bags HDPE bags are made from high-density polyethylene, a thermoplastic polymer known for its strength, durability, and resistance to moisture and chemicals. HDPE bags are typically manufactured through a process called blown film extrusion, where molten HDPE resin is extruded through a circular die to form a tube. The tube is then flattened and cooled, resulting in a thin, flexible film that can be further processed into bags of various sizes and thicknesses by HDPE bag manufacturers. Applications of HDPE Bags

HDPE bags find applications across a wide range of industries and sectors: 1.Agriculture: Used for packaging fertilizers, seeds, grains, and animal feed. 2.Construction: Ideal for storing and transporting cement, sand, gravel, and other building materials. 3.Retail: Commonly used as shopping bags, garbage bags, and packaging for retail products. 4.Transportation: Used for packaging goods for shipping and logistics, including bulk materials and commodities. 5.Healthcare: Used for medical waste disposal and storage of pharmaceuticals. Benefits of HDPE Bags HDPE bags offer several benefits that make them popular choices for packaging: 1.Strength and Durability: HDPE bags are strong and tear- resistant, capable of withstanding heavy loads and rough handling. 2.Moisture Resistance: The inherent moisture resistance of HDPE makes these bags suitable for storing and transporting moisture-sensitive materials.

3.Chemical Resistance: HDPE bags are resistant to a wide range of chemicals, making them suitable for packaging hazardous substances and industrial chemicals. 4.Recyclability: HDPE is a recyclable material, allowing used bags to be recycled and reused in the production of new products, contributing to sustainability efforts. 5.Cost-Effectiveness: HDPE bags are cost-effective packaging solutions, offering a balance of performance and affordability for businesses of all sizes. Environmental Impact of HDPE Bags While HDPE bags offer many benefits, they also raise environmental concerns, particularly regarding plastic pollution and waste management. To mitigate these concerns, efforts are underway to promote recycling, reduce single-use plastic consumption, and develop biodegradable alternatives to traditional HDPE bags. Best Practices for Using HDPE Bags To maximize the benefits of HDPE bags while minimizing their environmental impact, consider the following best practices: 1.Reduce, Reuse, Recycle: Implement recycling programs to collect and recycle used HDPE bags. Encourage consumers to reuse bags whenever possible. 2.Choose Sustainable Alternatives: Explore alternative packaging materials, such as biodegradable plastics or paper-

based packaging, for applications where HDPE bags may not be necessary. 3.Proper Disposal: Dispose of used HDPE bags responsibly by recycling them or disposing of them in designated waste collection facilities. 4.Support Recycling Initiatives: Partner with recycling facilities and organizations to promote recycling education and infrastructure development in your community. Conclusion HDPE bags play a vital role in packaging and transportation across various industries. They come in a wide range of sizes and strengths, including HDPE bags 50 kg which are ideal for heavy-duty applications. While they offer numerous benefits, it s essential to consider the environmental impact of all plastic packaging, including HDPE bags, and adopt sustainable practices to minimize plastic pollution. By understanding the composition, applications, and best practices associated with HDPE bags, businesses can make informed decisions that balance their packaging needs with environmental responsibility. Frequently Asked Questions (FAQs): 1.FAQ: What types of HDPE bags do Singhal Industries offer? Answer: Singhal Industries provides a wide range of HDPE bags, including those tailored for agriculture, construction, retail, transportation, and healthcare applications. These bags come in

various sizes, thicknesses, and configurations to meet diverse packaging needs. 2. FAQ: Are Singhal Industries HDPE bags recyclable? Answer: Yes, Singhal Industries is committed to sustainability, and our HDPE bags are recyclable. We encourage our customers to participate in recycling programs to ensure responsible disposal and contribute to environmental conservation efforts. 3. FAQ: Can Singhal Industries customize HDPE bags according to specific requirements? Answer: Absolutely! Singhal Industries offers customization options for HDPE bags, allowing customers to tailor the size, thickness, color, and printing designs to their exact specifications. Our team works closely with clients to deliver personalized packaging solutions that meet their unique needs and preferences.