Development Updates for ProtoDUNE Phase II: CRP Modifications and Testing

Updates on the development of Charged Readout Plane (CRP) for ProtoDUNE Phase II driven by lessons from commissioning and operation in ProtoDUNE-DP. Major topics include modifications for CRP mechanical structure, new LEM development, cold box improvements, and testing plans. Detailed steps per system and a timeline for CRP development, testing, and production are outlined, aiming to achieve readiness by early 2022.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

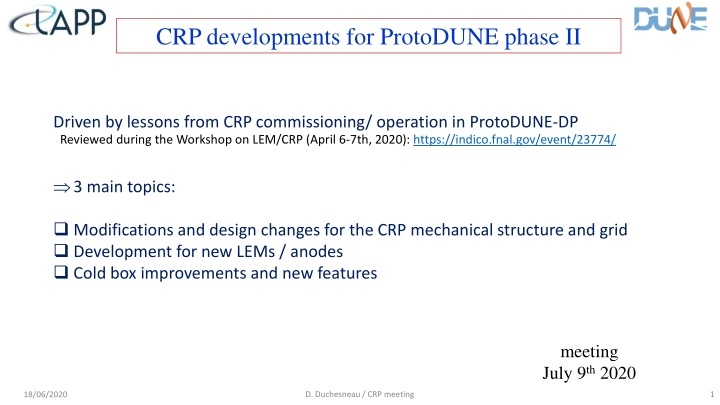

CRP developments for ProtoDUNE phase II Driven by lessons from CRP commissioning/ operation in ProtoDUNE-DP Reviewed during the Workshop on LEM/CRP (April 6-7th, 2020): https://indico.fnal.gov/event/23774/ 3 main topics: Modifications and design changes for the CRP mechanical structure and grid Development for new LEMs / anodes Cold box improvements and new features meeting July 9th 2020 D. Duchesneau / CRP meeting 1 18/06/2020

Development for CRP component tests in 2020 and 2021 Creation of a 1x1m mini CRP, for validation of : New LEM / Anode design Charge collection (resistive combs) Spark guides Instrumentation Thermal LevelMeters Deformationprobes ... To be used in the coldBox test facility at CERN using a special supporting beam to adapt on cryostat roof: Cold box in Bld 182 at CERN Assembly of the structure and availability by 10/2020 Cold box new features foreseen by CERN: Cathode system for drift in LAr Purification system to get gas purity similar to DP conditions Surface perturbation system to generate wavy conditions ProtoDUNE-DP CRP1 and CRP2 in Nov 2019 Cold box test of CRP2 in Dec 2018 LAr level 5mm above Grid 18/06/2020 2 D. Duchesneau / CRP meeting

Main steps per system (to be fine-grained and correlate in time): MiniCRP: Mini-CRPs mechanical test in Cold Box Mini-CRPs design & prod. assembly LEMs: LEM tests at CEA of various configurations 4 Mini CRP 2x2 Cold Box test LEM Design optimisation LEM prod when LEMs validated LEMs /anode prod CRP structure, assembly and tests: CRP Full dummy CRP0 assembly and production + fake LEMs/anodes CRP Full CRP0 Planarity, grid / Cold test 1bis cold test CRP frame and grid sub-Parts manufacturing CRPs & tooling design 1bis prod CRP CRP 2bis cold test 2bis prod Cold Box: roof modification for SGFT + instrumentation Purity system implementation Original cold box system Cathode implementation Cold box tests 18/06/2020 3 D. Duchesneau / CRP meeting

CRP development - tests - production timeline Timeline to update with cold box readiness and LEM status July 2020 August 2021 January 2021 October 2020 April 2021 March 2022 CRPs & tooling design CRP frame and grid sub-Parts manufacturing Full CRP0 Planarity, grid / Cold test Production of dummy CRP Cold test different grid, guard ring, comb structures, fake LEMs/anodes LEMs /anode prod LEMs /anode prod LEM Design for 2x2 + iteration 4 Mini CRP 2x2 tests LEM prod Production final CRPs Cold test Installation in the cryostat CRP 1bis test CRP 1bis prod Mini-CRPs design & prod. CRP 2bis prod CRP 2bis test NP02 Cryostat available ? /2021 18/06/2020 4 D. Duchesneau / CRP meeting

18/06/2020 5 D. Duchesneau / CRP meeting

18/06/2020 6 D. Duchesneau / CRP meeting

Lessons from CRP commissioning/ operation in ProtoDUNE-DP From a critical point of view CRP Planarity is worse than expected at cold (4mm instead of 1.5 mm) => structure had to be revised to be more stiff Liquid argon surface instability complicated the operation: new design should integrate several modifications to be less sensitive => larger gap grid-LEM + additional device to get the LAr level knowledge at each CRP corner Extraction grid and LEM capacitive couplings and stability over time => revise the electrical configuration of both LEM and grid HV distribution Grid sparking (independently of the mechanism) is harmful to the readout electronics => need to be minimized and controlled to eliminate all risks for the electronics Guard rings to catch the potential sparks 0.2-0.4 sparks/h/CRP independent of cathode ON or OFF for V = 3.1 kV sparking rate increases by increasing the HV across the LEMs: 0.4 -0.9 sparks/h/CRP for V = 3.4 kV Existence of microphonic effects due to potential vibration mode => optimise the LEM-anode sandwich system and adapt possible damping Charging up of materials or ions may generate electrostatic effects (grid currents ) => Adapt a system to drain the charge Solutions and modifications for the structure and mechanical part: the CRP upgrade and improvements for phase II of protoDUNE-DP were presented at the April workshop 18/06/2020 7 D. Duchesneau / CRP meeting