Comprehensive Valve Selection Guide

CWT Valve brings years of experience in the valve industry, ensuring expert guidance and reliable products. We maintain rigorous quality standards, guaranteeing durable and efficient valves that meet or exceed industry requirements. We are ensuring you find the perfect solution for your needs.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Comprehensive Valve Comprehensive Valve Selection Guide Selection Guide Valves plays an important role for the many industrial processes. The valve is of flow regulating function of fluids, gases and slurry transfer. Being very thoughtful about what valve is to be selected is a very important notice when it comes to function, safety and longevity of the system. This guide provides an overview of key thoughts for How To Select Valve , including types of valves, material collection, sizing, and application-specific factors.

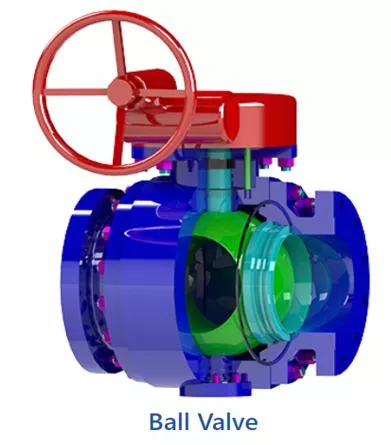

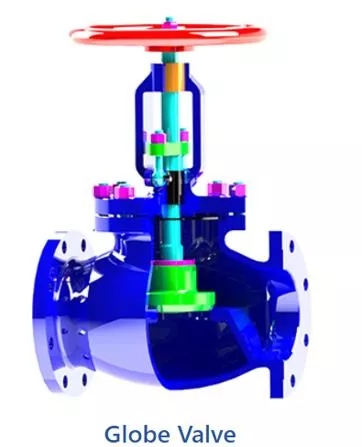

Kinds of Valves: Kinds of Valves: 1. Globe Valves: Ideal for strangling and regulating flow. Offer precise control over flow rates. Commonly used in stressful and high-temperature applications. 2. 2. Ball Valves: Ball Valves: Provide quick shutoff. Suitable for applications needful minimal restriction to flow. Offer excellent waterproofing properties. 3. 3. Butterfly Valves: Butterfly Valves: Compact design with quick operation. Suitable for large-diameter pipelines. Offer low pressure drop. 4. 4. Gate Valves: Gate Valves: Provide full flow with minimal pressure drop. Ideal for on/off service. Commonly used in pipelines with straight-through flow.

1. 1. Check Valves: Check Valves: Prevent backflow and ensure one-way flow. Available in various designs including swing, lift, and ball check valves. Essential for preventing system damage due to reverse flow. Valve Material Selection Valve Material Selection: : 1. Stainless Steel: Resistant to corrosion, high temperatures, and harsh chemicals. Suitable for a wide range of applications including food processing, pharmaceuticals, and chemical processing. 2. Carbon Steel: Cost-effective option for general-purpose applications. Offers good strength and durability. Suitable for high-pressure and high-temperature environments. 3. Brass: Provides excellent corrosion resistance and machinability. Commonly used in plumbing and water distribution systems. Not suitable for corrosive environments containing certain chemicals.

1. 1. PVC (Polyvinyl Chloride): PVC (Polyvinyl Chloride): Lightweight and cost-effective option. Ideal for applications involving water and mild corrosive fluids. Limited temperature and pressure capabilities compared to metal valves. Sizing and Flow Characteristics: Sizing and Flow Characteristics: 1. Flow Rate: Determine the required flow rate based on process requirements. Consider factors such as pressure drop, velocity, and fluid properties. 2. Valve Size: Valve Size: 2. Select valve size based on the desired flow rate and pipe diameter. Ensure compatibility with existing piping systems. Cv Value: Value: 3. 3. Cv Evaluate the valve's flow capacity using the Cv (flow coefficient) value. Choose a valve with an appropriate Cv for the desired flow conditions. 4. Pressure Rating: Pressure Rating: 4. Select valves with pressure ratings that exceed system requirements to ensure safety and reliability. Consider both upstream and downstream pressure conditions.

Application Application- -Specific Considerations: Specific Considerations: 1. Temperature and Pressure: Choose valves capable of operating within the specified temperature and pressure ranges of the application. Consider fluctuations in temperature and pressure during normal operation. 2. Media Compatibility: Media Compatibility: 2. Select materials that are compatible with the fluid being handled to prevent corrosion, contamination, or degradation. Consider factors such as pH, viscosity, and chemical composition. 3. Environmental Factors: Environmental Factors: 3. Evaluate environmental conditions such as temperature extremes, humidity, and exposure to corrosive agents. Choose Valve Selection Tool with suitable protective coatings or materials for long-term durability. 4. Regulatory Compliance: Regulatory Compliance: 4. Ensure that selected valves comply with industry standards and regulations, such as ASME, API, and ANSI. Consider certifications required for specific applications, such as FDA approval for food and pharmaceutical industries.

Why Should Approach CWT Valve To Buy Valve Why Should Approach CWT Valve To Buy Valve Approaching CWT Valve for valve purchases ensures access to high- quality products backed by years of industry expertise. With a reputation for reliability and performance, CWT Valve offers a comprehensive range of valves suitable for various applications. Their commitment to customer satisfaction, coupled with efficient service and competitive pricing, makes them a trusted choice in the valve market. Whether for industrial, commercial, or residential use, choosing Valve Selection Guide ensures peace of mind and optimal performance for your fluid control needs. Conclusion Conclusion Selecting the right valve is essential for optimizing process efficiency, ensuring safety, and minimizing downtime. By considering factors such as valve type, material selection, sizing, and application-specific requirements, engineers and operators can make informed decisions that meet the needs of their systems. Consultation with valve manufacturers and industry experts can further enhance the selection process, leading to reliable and cost-effective solutions.

CONTACT DETAILS: Phone: +1 403-8006686 Email: info@cwtvalve.com Website: cwtvalve.com Address: 234-5149 Country Hills Blvd NW, Calgary, AB, Canada T3A 5K8 THANK YOU