Comparative Analysis of Pool Boiling Heat Transfer for Different Pore Sizes

Pool boiling heat transfer using porous metals is crucial for various industrial applications. This project involves brazing porous copper of various pore sizes to a copper plate, analyzing and comparing their heat transfer performance. Another related project focuses on simulating the joining of different pore sizes of porous copper to a copper plate to investigate flow and heat characteristics. Additionally, an investigation on brazing diamond grits using a stainless steel woven interlayer is explored to enhance bonding strength.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

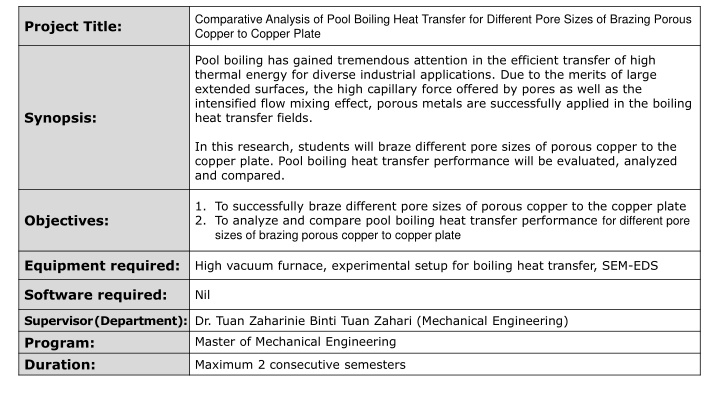

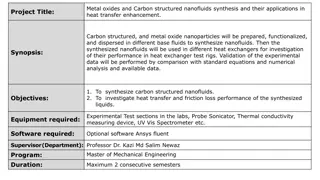

Comparative Analysis of Pool Boiling Heat Transfer for Different Pore Sizes of Brazing Porous Copper to Copper Plate Project Title: Pool boiling has gained tremendous attention in the efficient transfer of high thermal energy for diverse industrial applications. Due to the merits of large extended surfaces, the high capillary force offered by pores as well as the intensified flow mixing effect, porous metals are successfully applied in the boiling heat transfer fields. Synopsis: In this research, students will braze different pore sizes of porous copper to the copper plate. Pool boiling heat transfer performance will be evaluated, analyzed and compared. 1. To successfully braze different pore sizes of porous copper to the copper plate 2. To analyze and compare pool boiling heat transfer performance for different pore sizes of brazing porous copper to copper plate Objectives: Equipment required: High vacuum furnace, experimental setup for boiling heat transfer, SEM-EDS Software required: Nil Supervisor(Department): Dr. Tuan Zaharinie Binti Tuan Zahari (Mechanical Engineering) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Simulation on Pool Boiling Heat Transfer Performance for Joining Different Pore Sizes of Porous Copper to Copper Plate Project Title: Pool boiling has gained tremendous attention in the efficient transfer of high thermal energy for diverse industrial applications. Due to the merits of large extended surfaces, the high capillary force offered by pores as well as the intensified flow mixing effect, porous metals are successfully applied in the boiling heat transfer fields. Synopsis: In this research, students will design the joining of different pore sizes of porous copper to the copper plate. Then, the simulation will be done to analyze the pool boiling heat transfer performance for different pore sizes. 1. To design and simulate the joining of different pore sizes porous copper to copper plate 2. To investigate the flow and heat characteristics of joining different pore sizes porous copper to copper plate 3. To analyzed pool boiling heat transfer performance for the design Objectives: Equipment required: High performance computer for design and simulation Software required: AutoCAD, Ansys Fluent CFD software Supervisor(Department): Dr. Tuan Zaharinie Binti Tuan Zahari (Mechanical Engineering) Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Project Title: Investigation on Brazing Diamond Grits by utilizing Stainless Steel Woven Interlayer Diamond is the hardest material known and it is widely used in tool cutting, grinding, and polishing operations. However, due to its properties that are low reactivity, diamond grits are difficult to attach to tool matrixes. Commonly, diamond grits are embedded in tool surfaces by electroplating, sintering, and other processes, which may present limitations when trying to achieve an adequate level of strength. Therefore, it is very important to develop and apply brazing technology to manufacture diamond tools because of their advantages. Recent works have been reported on the progress and use of active filler metals of Ag Cu Ti and Ni Cr to bond diamond grits on tool surfaces, providing better performance in comparison with electroplating or sintering processes. However, utilizing stainless steel woven as interlayer and Ag Cu Ti to bond diamond grits on tool surfaces has not yet been explored. The diamond grits will be arranged on a stainless steel woven. A stainless steel plate will be used as a base at the bottom and the Ag-Cu-Ti filler metal will be placed in between the stainless steel woven and plate. Synopsis: It is expected that by utilizing stainless steel woven interlayer, the residual stress developed at the interface of diamond grits and stainless steel could be reduced. The stainless steel woven interlayer also is expected to facilitate the dispersion of diamond grits and increase the effectiveness of manufacturing diamond tools. 1. To successfully braze diamond grits to stainless steel by utilizing stainless steel woven interlayer 2. To investigate the effects of parameters on joining diamond grits to stainless steel. Objectives:

Classification of high voltage cable joint defects using support vector machine and noise reduction on partial discharge signals Project Title: In this work, classification of high voltage cable joint defect types using support vector machine and noise reduction techniques on partial discharge signals will be performed. Four cross-linked polyethylene (XLPE) cable joints with artificially created defects will be prepared based on the defects commonly encountered on site. Different noise reduction techniques will be applied to denoise the PD signals. The denoised signals will be used as a feature for classification of defects in cable joints using support vector machine. The classification results will be compared between the proposed method and the existing works to evaluate the performance of the applied techniques. 1. To perform measurement of partial discharge (PD) on artificially-prepared cable joint defects 2. To apply support vector machine and various noise reduction methods on PD signals for classification of XLPE cable joint defects 3. To compare the classification results between the proposed method and the existing works Synopsis: Objectives: Equipment required: Software required: Partial discharge measurement setup, high voltage generation kit, cable joint MATLAB, partial discharge analysis software Supervisor(Department): Assoc. Prof. Ir. Dr. Hazlee Azil Illias (Electrical) Program: Master of Power System Engineering / Master of Engineering (Power System) Duration: Maximum 2 consecutive semesters