Caterpillar Cat TH82 Telehandler (Prefix 3KN) Service Repair Manual Instant Download (3KN00001 and up)

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

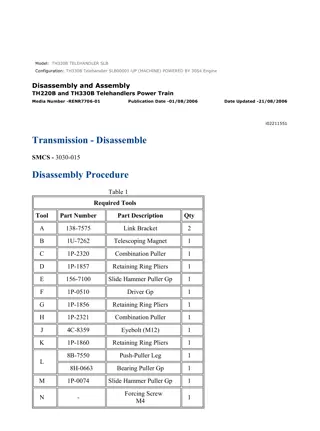

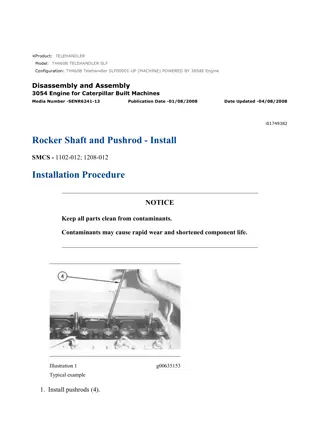

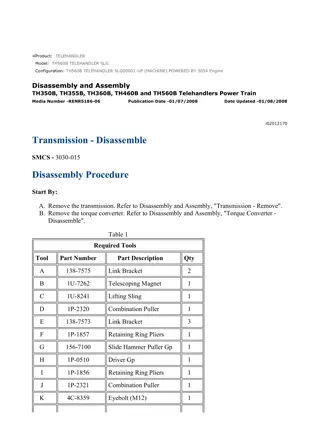

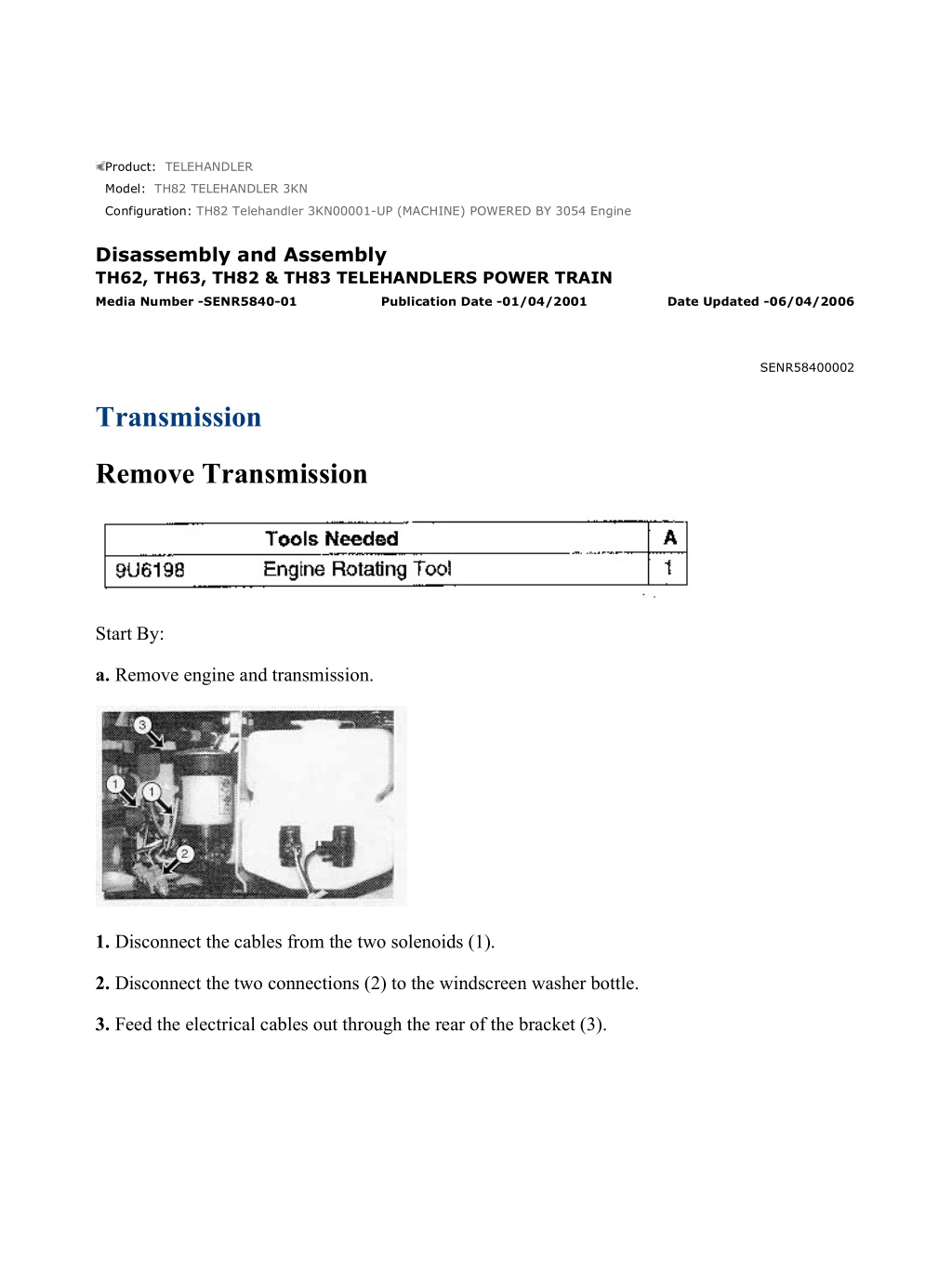

w 1/112(W) Product: TELEHANDLER Model: TH82 TELEHANDLER 3KN Configuration: TH82 Telehandler 3KN00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly TH62, TH63, TH82 & TH83 TELEHANDLERS POWER TRAIN Media Number -SENR5840-01 Publication Date -01/04/2001 Date Updated -06/04/2006 SENR58400002 Transmission Remove Transmission Start By: a. Remove engine and transmission. 1. Disconnect the cables from the two solenoids (1). 2. Disconnect the two connections (2) to the windscreen washer bottle. 3. Feed the electrical cables out through the rear of the bracket (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 2/112(W) 4. Disconnect the pipe (4) from the fuel filter (5). 5. Remove two bolts (6) and washers (7) from the bracket (3). 6. Disconnect the air cleaner pipe (8), undo the two spring clips (9) and remove the air cleaner assembly. 7. Remove three bolts (10) and washers (11) and remove bracket (3). 8. Prise out the access cover (12). 9. Assemble tool (A) to the fan belt pulley. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 3/112(W) 10. Using tool (A) to rotate the engine, align and remove the eight drive plate bolts (13) through the access hole. 11. Attach a sling and suitable lifting equipment and support the transmission assembly. 12. Remove eleven bolts (14), washers (15) and remove the transmission assembly. Weight of transmission is approximately ... 250Kg (550 lbs.). Install Transmission. 1. Install two ... 63,5 mm (2.5 in)guide studs in two of the transmission mounting holes to assist in aligning the transmission. 2. Install a ... 101,6 mm (4.0 in.)guide stud in one of the drive plate mounting holes to assist in alignment. Rotate the drive plate to align the stud with the flywheel hole \ access hole in the flywheel housing. 3. Position the transmission on the mounting with the drive plate guide stud through the flywheel \ access hole and install bolts (14) and washers (15). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 4/112(W) 4. Remove the two guide studs from the transmission mounting holes and install the remaining two bolts (14) and washers (15). Torque tighten bolts to ... 50 - 60 Nm 37.5 - 45.0 lb. ft.). 5. Remove the drive plate guide stud and install one bolt (13). Do not tighten the bolt. Using tool (A), rotate the engine and install the remaining seven drive plate bolts (13). Torque tighten bolts to ... 35 - 45Nm (26 - 33.7 lb.ft.). 6. Install access cover (12) and remove tool (A) from the fan belt pulley. Remove slings and lifting equipment from the transmission. 7. Position bracket (3) on the transmission and install bolts (10) and washers (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 5/112(W) 8. Install air cleaner assembly in mounting and secure with two clips (9). Connect air cleaner pipe (8). 9. Install bolts (6) and washers (7). 10. Connect fuel pipe (4) onto fuel filter (5). 11. Feed electrical cables through the bracket (3) and connect the two connectors (2) to the windscreen washer bottle. 12. Reconnect the cables to the two solenoids (1). End By: a. Install engine and transmission. Disassemble Transmission. Start By: a. Remove torque converter. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 6/112(W) 1. Remove filter assembly (1), using tool (A). 2. Remove pressure regulator and sleeve assembly (2), using tool (B). Place assembly aside for future disassembly and assembly. 3. Remove the bolts and washers and remove the charging pump (3) and gasket (4). 4. Remove bolts (5) and (6) and washers (7) from converter housing (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 7/112(W) 5. Remove converter housing (8) and gasket (9). Place assembly aside for future disassembly and assembly. 6. Remove impeller hub gear (10) from stator support. 7. Remove pump drive idler gear washer (11). 8. Remove pump drive idler gear (12) and needle bearing (13). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 8/112(W) 9. Remove solenoid valve cartridge retaining nut (14) and 'O' ring seal (15). 10. Remove solenoid coil (16) and 'O' ring seal (17). 11. Remove valve cartridge (18) and 'O' ring seal (19). 12. Repeat operations 9 through 11 for remaining solenoid valves. 13. Remove bolts (20) and washers (21) from spacer plate (22). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 9/112(W) 14. Ease spacer plate (22) away from transmission housing at dowel pin holes. 15. Remove spacer plate (22) and gasket (23). Place assembly aside for future disassembly and assembly. 16. Remove 1st and 2nd clutch assembly (24). Place assembly aside for future disassembly and assembly. 17. Remove forward and reverse clutch assembly (25). Place assembly aside for future disassembly and assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 10/112(W) 18. Remove 'high' and 3rd clutch assembly (26). Place assembly aside for future disassembly and assembly. 19. Remove retaining ring (27) from intermediate bore plug. 20. Remove bore plug (29) and remove 'O' ring seal (30). 21. Remove 3rd clutch to bearing retaining ring (31). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 11/112(W) 22. From rear of housing, tap 3rd clutch gear and hub (32) from bearing (33). 23. Remove bearing (34) from clutch gear and hub (32). 24. From inside housing, drive bearing (33) out of rear of housing. 25. Remove inner bearing locating ring (35). 26. Remove outer bearing locating ring (36). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 12/112(W) 27. Turn output flange assembly (37) to horizontal position as illustrated. Remove retaining ring (38) from its groove. Retaining ring (38) cannot be removed from the output flange at this time. 28. Remove output flange assembly (37) from housing. Place assembly aside for future disassembly and assembly. 29. Remove bearing locating ring (39). 30. Remove output gear to shaft retaining ring (40). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 13/112(W) 31. From rear of housing, remove plug retaining ring (41). 32. Remove bore plug (42) and remove 'O' ring seal (43). 33. From front of housing, drive output shaft (44) out through rear of housing. 34. Remove output gear (45). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 14/112(W) 35. From front of housing, drive output shaft rear bearing (46) out through rear of housing. 36. Remove bearing locating ring (47). 37. Remove modulator valve housing (48) and 'O' ring seal (49). 38. Remove regulator valve sleeve assembly (50) and 'O' ring seal (51). Place assembly aside for future disassembly and assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 15/112(W) 39. Screw a length of 5/16 - 24threaded rod into diverter sleeve (52) and remove diverter sleeve from housing. 40. Repeat operations 37 through 39 for remaining modulator valve. 41. Remove supply tube clamp screw (53). Clamp screw can not be re-used and must be replaced on assembly. 42. Push supply tube forward and remove 'O' ring seal (54). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 16/112(W) 43. Remove supply tube and screen assembly (55). 44. Remove distributor sleeve lock screw plug (56). 45. Remove distributor sleeve lock screw (57). 46. Assemble a suitable puller to distributor sleeve (58) and bearing (59). 47. Remove distributor sleeve (58) and bearing (59). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 17/112(W) Disassemble and Assemble 1st and 2nd Clutch Disassemble 1st Clutch 1. Remove clutch shaft oil sealing rings (1). 2. Remove front bearing retaining ring (2). 3. Using a suitable puller, remove front bearing (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 18/112(W) 4. Remove outer thrust washer (4), bearing (5) and inner thrust washer (6). 5. Remove clutch gear (7) and two pilot bearings (8). 6. Remove outer thrust washer (9), bearing (10) and inner thrust washer (11). 7. Extract clutch disc end plate retaining ring (12). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 19/112(W) 8. Remove clutch disc end plate (13). 9. Remove inner and outer clutch discs (14) and (15). Do not remove the retaining ring (16) without the use of Tool (A). The retaining ring holds the retainer (17) and springs (18) in a compressed condition. Sudden release of the springs can cause personal injury. 10. Using Tool (A), compress disc springs and remove retaining ring (16). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 20/112(W) 11. Remove retaining ring retainer (17). 12. Remove disc springs (18). Secure disc springs together as an assembly and identify for future assembly. 13. Remove clutch piston wear plate (19). 14. Remove clutch piston (20) and remove inner and outer sealing rings (21) and (22). Disassemble 2nd Clutch. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 21/112(W) 1. Remove clutch shaft rear bearing (1). 2. Using a suitable puller, remove gear (2) and rear bearing inner race (3). 3. Remove gear locating ring (4) from shaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 22/112(W) 4. Remove thrust bearing and clutch gear retaining ring (5). 5. Remove outer thrust washer (6), thrust bearing (7) and inner thrust washer (8). 6. Remove clutch gear and hub (9) and two gear bearings (10). 7. Remove outer thrust washer (11), thrust bearing (12) and inner thrust washer (13). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 23/112(W) 8. Extract clutch disc end plate retaining ring (14). 9. Remove clutch disc end plate (15). 10. Remove inner and outer clutch discs (16) and (17). Do not remove the retaining ring (18) without the use of Tool (A). The retaining ring holds the retainer (19) and springs (20) in a compressed condition. Sudden release of the springs can cause personal injury. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

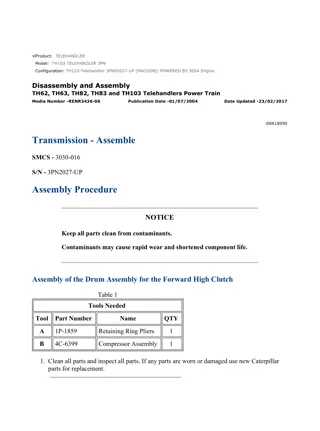

Suggest: For more complete manuals. Please go to the home page. https://www.ebooklibonline.com If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 24/112(W) 11. Using Tool (A), compress disc springs and remove retaining ring (18). 12. Remove retaining ring retainer (19). 13. Remove disc springs (20). Secure disc springs together as an assembly and label to identify for future assembly. 14. Remove clutch piston wear plate (21). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

w 25/112(W) 15. Remove clutch piston (22) and remove inner and outer sealing rings (23) and (24). Assemble 1st clutch. NOTICE Prior to assembly make sure all components are clean. Precision fitted components will be damaged by foreign material. 1. Inspect two bleed valves in the clutch drum and ensure they are clean and free from any foreign material. 2. Install clutch piston inner sealing ring (21) into clutch piston (20). Size the sealing ring by holding a round object against the new sealing ring as illustrated and rotate the piston until the sealing ring is flush with the outer diameter of the piston sealing ring groove. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/6/18

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com