Caterpillar Cat D6H TRACK-TYPE TRACTOR (Prefix 3ED) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

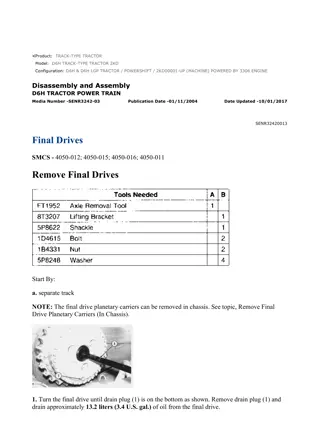

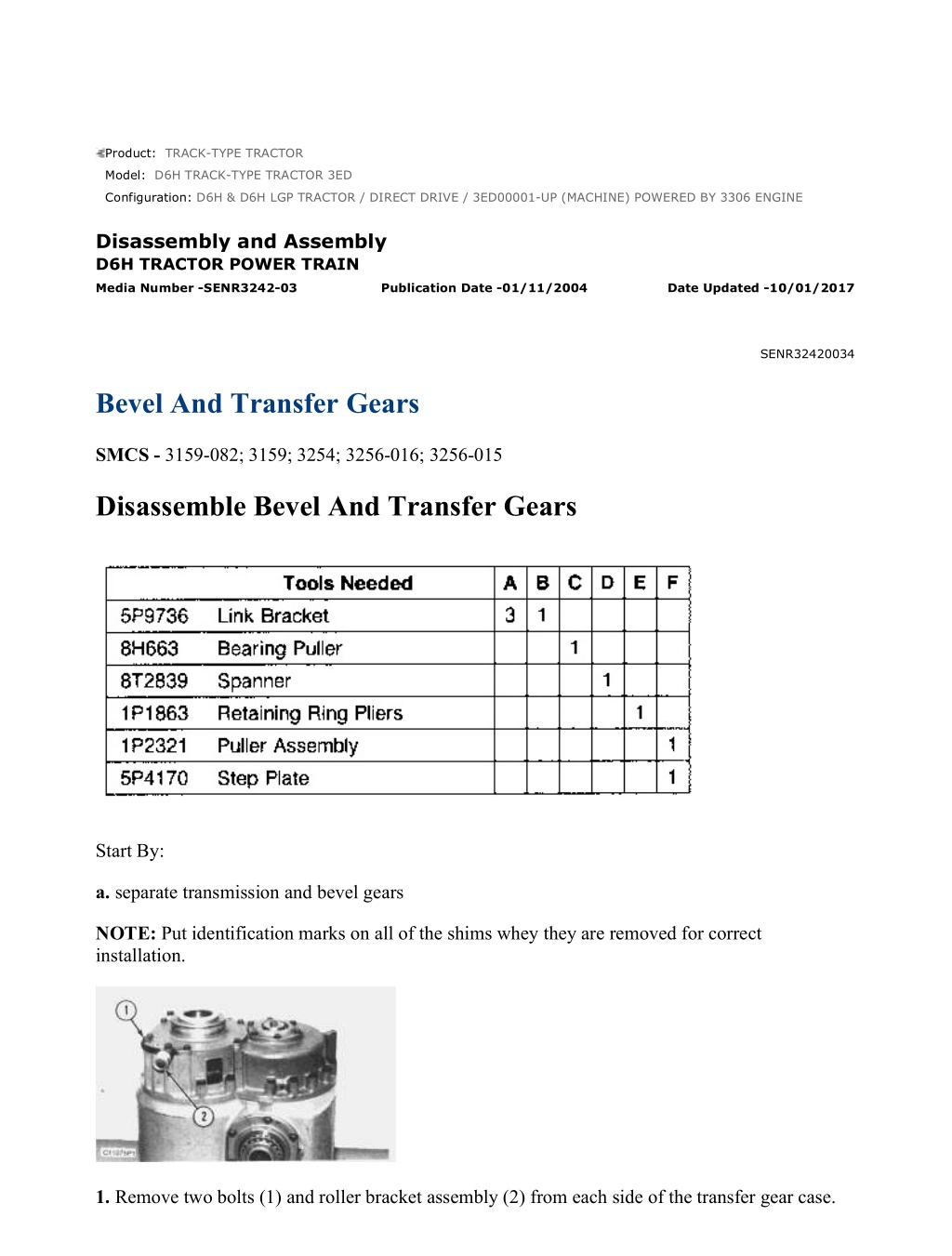

w 1/17(W) Product: TRACK-TYPE TRACTOR Model: D6H TRACK-TYPE TRACTOR 3ED Configuration: D6H & D6H LGP TRACTOR / DIRECT DRIVE / 3ED00001-UP (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly D6H TRACTOR POWER TRAIN Media Number -SENR3242-03 Publication Date -01/11/2004 Date Updated -10/01/2017 SENR32420034 Bevel And Transfer Gears SMCS - 3159-082; 3159; 3254; 3256-016; 3256-015 Disassemble Bevel And Transfer Gears Start By: a. separate transmission and bevel gears NOTE: Put identification marks on all of the shims whey they are removed for correct installation. 1. Remove two bolts (1) and roller bracket assembly (2) from each side of the transfer gear case. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 2/17(W) 2. Remove sixteen bolts (4) that hold transfer gear case (3) to the bevel gear case. 3. The weight of the transfer gear case is 101 kg (223 lb). Install tooling (A), and attach a hoist as shown. Remove transfer gear case (3) from the bevel gear case. 4. Remove the six bolts that hold cage (6) to transfer gear case (3). 5. Install two 1/2 " - 13 NC forcing screws (5), and tighten evenly. Remove the cage and shims from the transfer gear case. 6. Remove lip-type seal (7) and O-ring seal (8) from cage (6). NOTICE Bearing cup (9) and bearing (10) will be damaged if they are removed. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 3/17(W) 7. If necessary, remove bearing cup (9) and bearing (10) from cage (6). 8. Remove transfer gear (11) from transfer gear case (3). NOTICE Bearing cones (12) will be damaged if they are removed from transfer gear (11). 9. If necessary, remove two bearing cones (12) from transfer gear (11). 10. Remove the six bolts, and install two 1/2 " - 13 NC forcing screws (14) in cage (13). Tighten the forcing screws evenly, and remove cage (13) and the shims from transfer gear case (3). 11. Remove the bearing cup from cage (13). 12. Remove bearing cup (15) from transfer gear case (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 4/17(W) 13. Remove the bolt and retainer from pinion gear assembly (16). 14. The weight of the pinion gear assembly is 33 kg (73 lb). Install tooling (B), and attach a hoist. Remove pinion gear assembly (16) from the bevel gear case. 15. Remove the pinion gear assembly bearing cup from the bevel gear case. 16. Put the pinion gear assembly in a press as shown. Remove transfer gear (18) and bearing cone (17) from pinion gear (19). 17. Use tooling (C) and a press, and remove bearing cone (19) from pinion gear (20). 18. Bend the lock tab away from spanner nut (22). 19. Put a pry bar in between the bolt heads on the bevel gear to stop the rotation of the bevel gear and shaft. 20. Use tool (D), and remove spanner nut (22). Remove lock (21). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 5/17(W) 21. The weight of bevel gear and shaft (23) is 55 kg (121 lb). Use nylon straps and a hoist to support the bevel gear and shaft so the bearings can be removed. 22. Remove the six bolts, and install two 1/2 " - 13 NC forcing screws (25). Tighten the forcing screws evenly, and remove cage (24), two bearing cones (26), the spacer between bearing cones and the shims from the bevel gear case. 23. Remove the bearing cups and center ring from cage (24). 24. Remove the six bolts, and install two 1/2 " - 13 NC forcing screws (27). Tighten the forcing screws evenly, and remove cage (28) and the bearing from the bevel gear case. 25. Use the hoist, and remove bevel gear and shaft (23) from the bevel gear case. 26. Install a 1/4 " - 20 NC bolt, and remove dowel (30) from cage (28). Remove race and roller assembly (29). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 6/17(W) 27. Use tool (E), and remove the retaining ring from bevel gear shaft (23). 28. Use tooling (F), and remove bearing race (32) from the bevel gear shaft. 29. Remove 12 bolts (31) and nuts. Install three 1/2 " - 13 NC forcing screws in bevel gear (33). Tighten the forcing screws evenly, and remove the bevel gear from the bevel gear shaft. 30. Remove the tube assemblies from the bevel gear housing. Assemble Bevel And Transfer Gears 1. Put bevel gear (5) in position on bevel gear shaft (3). Install twelve bolts (2) and nuts. 2. Put two 1/2 " - 13 NC bolts into two of the forcing screw holes, and use a bar to hold the bevel gear and shaft. Tighten bolts (2) to a torque of 540 50 N m (400 37 lb ft). 3. Heat bearing race (1) to a maximum temperature of 135 C (275 F), and install it on the bevel gear shaft. 4. Use tool (A), and install retaining ring (4) on bevel gear shaft (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 7/17(W) 5. Install three tube assemblies (6) into the bevel gear case. 6. Use lifting straps and a hoist, and put bevel gear and shaft (3) in position in the bevel gear case. 7. Put bearing cone (7) in position on bevel gear shaft. 8. Align the dowel hole in bearing race (9) with the hole in cage (8), and install the bearing in the cage. Install dowel (10) in the cage that holds the bearing in place. 9. Put cage (8) in position on the bevel gear case, and install six bolts (11). Tighten the bolts to a torque of 130 15 N m (95 11 lb ft). 10. Lower the temperature of two bearing cups (12), and install with ring (13) into cage (14). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 8/17(W) 11. Install cage (14) without shims. Loosely install bolts (15) that hold cage (14) to the bevel gear case. 12. Install bearing cone (17) on the bevel gear shaft. 13. Align the notch in the bevel gear shaft with the tooth on washer (16), and install washer (16). 14. Align the teeth on the lock with the notch in the bevel gear shaft, and put the lock in position. 15. Put 5P3931 Anti-Seize Compound on the threads and face of spanner nut (18). Install spanner nut (18) on the bevel gear shaft. 16. Use tooling (B), and tighten nut (18) to a torque of 612 68 N m (452 49 lb ft). 17. Heat bearing cone (20) to a maximum temperature of 135 C (275 F), and install the bearing on pinion gear shaft (19). Use a 0.03 mm (.001 in) feeler gauge to make sure the bearing is seated against the shoulder of the pinion shaft. 18. Align the splines, and install transfer gear (22) onto pinion gear shaft (19). 19. Heat bearing (21) to a maximum temperature of 135 C (275 F), and install the bearing onto the pinion shaft. Use a 0.03 mm (.001 in) feeler gauge to make sure the bearing is seated against shoulder (23) of the pinion shaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 9/17(W) 20. Install tooling (C) onto the pinion, and attach a hoist. Lower pinion and transfer gear assembly (24) into position in the bevel gear case. 21. Lower the temperature of bearing cup (25), and install into transfer gear case (26). 22. Lower the temperature of bearing cup (28), and install into cage (27). 23. Heat two bearing cones (29) to a maximum temperature of 135 C (275 F). Install the two bearing cones onto lower transfer gear (30). Use a 0.03 mm (.001 in) feeler gauge to make sure the bearings are against the shoulders on the transfer gear. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 10/17(W) 24. Put lower transfer gear (30) into position in the transfer gear case (26). 25. Use tooling (D), and install bearing (33) in cage (32). 26. Lower the temperature of bearing cup (31), and install it in cage (32). 27. Put 7M7260 Liquid Gasket Material in the seal bore of cage (32). Use tooling (D), and install lip-type seal (34) in cage (32). Put clean oil on the lip of the seal. 28. Put glycerine on O-ring seal (35), and install it onto the cage. 29. Put cage (32) without shims in position on transfer gear case (26). Install two bolts (37) and (38) 180 apart, but do not tighten at this time. 30. Put cage (27) without shims in position on transfer gear case (26). Install two bolts (36) 180 apart, but do not tighten at this time. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 11/17(W) 31. Install tooling (E) onto transfer gear case (26), and attach a hoist. NOTICE Make sure bolts (36), that hold cage (27) in place on the transfer gear case, are loose. 32. Put transfer gear case (26) in position on the bevel gear case. Install 12 bolts (40) and washers, and tighten to a torque of 250 25 N m (185 18 lb ft). 33. Install bolt (39) and retainer. Tighten bolt (39) to a torque of 250 25 N m (185 18 lb ft). 34. Use the following steps to adjust the lower transfer gear bearing end play. a. Rotate the transfer gear at least three complete revolutions to seat the bearings, and tighten bolts (37) and (38) evenly to a torque of 2.25 N m (20 lb in). b. Rotate the transfer gear at least three complete revolutions to seat the bearings, and tighten bolts (37) and (38) evenly to a torque of 4.5 N m (40 lb in). c. Use a feeler gauge or a taper gauge, and measure the gap between cage (32) and the transfer gear case. Make the measurement at the edge of the cage in line with the center of two bolts (37) and (38). Average the two measurements. d. Add 0.23 mm (.009 in) to the dimension found in Step 34c. This will be the correct thickness of shims that should be used. 35. Remove cage (32). Put the correct thickness of shims in position on the transfer gear case. Put cage (32) in position, and install the six bolts that hold it. Tighten the six bolts to a torque of 130 15 N m (95 11 lb ft). The bearing end play will be 0.10 0.05 mm (.004 .002 in). It is not necessary to check the bearing end play if this procedure has been followed for adjustment. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 12/17(W) However, if a measurement of the bearing end play is desired, see Bevel And Transfer Gears, Bearing End Play Adjustment in this module. 36. Put two roller assemblies (41) in position, and install the two bolts that hold each one. Tighten the bolts to a torque of 250 25 N m (185 18 lb ft). 37. Use the following steps to adjust the upper transfer and pinion gear bearing end play. a. Rotate the transfer gear at least three complete revolutions to seat the bearings, and tighten bolts (36) evenly to a torque of 4.5 N m (40 lb in). b. Rotate the transfer gear at least three complete revolutions to seat the bearings, and tighten bolts (36) evenly to a torque of 9.0 N m (80 lb in). c. Use a feeler gauge or a taper gauge, and measure the gap between cage (27) and the transfer gear case. Make the measurement at the edge of the cage in line with the center of two bolts (36). Average the two measurements. d. Add 0.43 mm (.017 in) to the dimension found in Step 37c. This will be correct thickness of shims that should be used. 38. Remove cage (27). Put the correct thickness of shims in position on the transfer gear case. Put cage (27) in position, and install the six bolts that hold it. Tighten the six bolts to a torque of 130 15 N m (95 11 lb ft). The bearing end play will be 0.10 0.05 mm (.004 .002 in). It is not necessary to check the bearing end play if this procedure has been followed for adjustment. However, if a measurement of the bearing end play is desired, see Bevel And Transfer Gears, Bearing End Play Measurement in this module. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 13/17(W) 39. Put the bevel gear case on its side so the bevel gear shaft is in a vertical position with the bevel gear at the bottom. NOTICE It is important for the bevel gear to be in this position. The bevel gear must be held as far away from the pinion gear as possible when gear clearance (backlash) is set. 40. Install a 5/8 " - 11 NC (dog point) forcing screw (43) in the transfer gear case. Tighten the forcing screw until there is no measurement in the pinion gear. Make sure the forcing screw is in between the teeth of the gear. 41. Put tooling (F) in position, and check the gear clearance (backlash) between the bevel gear and pinion gear. The gear clearance (backlash) must be 0.30 + 0.12 - 0.10 mm (.012 + .005 - .004 in). Check the gear clearance (backlash) on three different teeth evenly spaced around the gear. 42. The difference between the high and low measurements must not be more than 0.15 mm (.006 in). 43. Install the correct amount of shims (42) under bearing cage (14). Install the six bolts in the cage, and tighten them to a torque of 130 15 N m (95 11 lb ft). 44. Check the gear clearance (backlash) to make sure it is still correct. If not, add or remove shims (42) as needed. NOTICE Forcing screw (43) must be removed. 45. Remove forcing screw (43) from the transfer gear case. End By: a. connect transmission and bevel gears https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 14/17(W) Bevel Pinion And Transfer Gears Bearing End Play Measurement The bevel pinion and transfer gears bearing end play should be adjusted according to the procedure in Assemble Bevel And Transfer Gears in this module. If that procedure is used, the bearing end play should be correctly set at 0.10 0.05 mm (.004 .002 in). NOTICE It is extremely important to load the bearings vertically in each direction (upward and downward) while making the measurements, otherwise false readings will result. If a check of bearing end play is desired, the measurement must be made only while the bearings are being rotated and loaded with the tooling shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 15/17(W) The 2P8257 Plate (6), also from the 2P8260 Liner Installer Group, requires an additional 5/8 16 mm ( in)diameter hole. Drill the hole for bolt (10) 25 mm (1 in) from the tapped center hole. See illustration C11109P1. Illustration C11108P1 shows the tooling order of assembly to check bearing clearance for the input transfer gear. The two adapters (4) clamp the transfer gear in between. Lever (7) is used to force the gear up or down. Two washers (1) fit into adapters (4) to center rod (5) in the gear. NOTE: Use the following steps to measure the bearing clearance for the input transfer gear. 1. Install the tooling in the transfer gear with threaded rod (5) and adapters (4) centered in the gear. Install rod (5) with the 5/8 " - 11 NC thread up. 2. Tighten one of nuts (8) on top of the adapter to prevent gear movement. Two nuts (3) can then be used to turn the gear. 3. Fasten modified plate (6) and lever assembly (7) to the housing with bolt (10) as shown. Use washers (11) to support the plate. 4. Put the slotted end of the lever in a level (horizontal) position on the threaded rod. Make sure there is 1 mm (.04 in) clearance between washers (2) and the lever. 5. Lubricate the washers so the assembly will turn smoothly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 16/17(W) 6. Put dial indicator (9) in position. Make sure the indicator foot is vertical and in contact with the top adapter. Lubricate the adapter surface for the dial indicator foot. 7. Push and hold the adapter down with the lever up, and use a ratchet wrench to turn the gear with two nuts (3). The gear must be rotated at least three revolutions. Watch the dial indicator needle as it moves back and forth. Stop rotating the gear at the point of maximum needle movement. NOTE: The needle may move back and forth during rotation due to runout in the adapter. The reading should be taken at the same location every time so the measurement will be accurate and consistent. 8. Mark the location (X) at the point of maximum needle movement on the adapter surface. See illustration C11109P1. Set the needle on the dial indicator to zero while forcing the gear down. 9. Pull the gear upward by pulling the lever down. while turning the gear at least three revolutions. Record the maximum needle reading obtained when the indicator foot is returned to location (X). This reading is the actual bearing clearance and should be 0.10 0.05 mm (.004 .002 in). 10. Repeat the procedure. If it has been correctly done, the result will be the same. NOTE: Use the following steps to measure the bearing clearance for the pinion gear. 11. Screw the 5/8 " - 18 NF end of threaded rod (5) into the pinion shaft. 12. Put the lever assembly and modified plate (6) in position, and install bolt (10) into the bearing retainer cage. Use washers (11) to support the plate. 13. Adjust nuts (8) so the slotted end of the lever is level (horizontal). 14. Allow 1 mm (.04 in) clearance between the lever and each washer (2). Lubricate both washers. 15. Put dial indicator (9) in position as shown. Make sure the indicator foot is vertical and in contact with the flat end surface of the pinion gear. Lubricate the flat end surface of the pinion gear for the dial indicator foot. 16. Rotate the pinion at least three revolutions while forcing the pinion down by lifting up on lever (7). Watch the dial indicator needle as it moves back and forth while the pinion is being rotated. Stop rotating the pinion at the point of maximum needle movement. Mark this location of maximum needle movement on the pinion gear surface. Set the needle to zero while forcing the pinion down. NOTE: The needle may move back and forth during rotation due to runout in the surface of the pinion gear. The reading should be taken at the same exact location every time so the measurement will be accurate and consistant. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 17/17(W) 17. Pull the pinion upward by pulling down on the lever while turning the gear at least three revolutions. Record the maximum needle reading obtained when the indicator foot is returned to the marked location. This reading is the actual bearing clearance and should be 0.10 0.05 mm (.004 .002 in). 18. Repeat the procedure. If it has been done correctly, the reading will be the same. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 1/29(W) Product: TRACK-TYPE TRACTOR Model: D6H TRACK-TYPE TRACTOR 3ED Configuration: D6H & D6H LGP TRACTOR / DIRECT DRIVE / 3ED00001-UP (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly D6H TRACTOR POWER TRAIN Media Number -SENR3242-03 Publication Date -01/11/2004 Date Updated -10/01/2017 SENR32420035 Transmission (Power Shift) SMCS - 3150-015; 3150-016 Disassemble Transmission (Power Shift) Start By: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 2/29(W) a. separate transmission and bevel gear 1. Put transmission in position on tooling (A). Put alignment marks on all of the housings for assembly purposes. 2. Remove three small O-ring seals (1) and large O-ring seal (2) from the transmission cover. 3. Remove plugs (5) and the springs behind them. 4. Remove bolt (4) and the retainer. Remove tube (6) and the seals from the tube. 5. Remove two tubes (3) and the seals from the tubes. 6. The weight of the transmission control valves and priority valve as a unit is 43 kg (95 lb). Install tooling (B) on the transmission control valve, and fasten a hoist as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 3/29(W) 7. Remove four bolts (7) that hold the transmission control valves to the planetary. Remove the transmission control valves and priority valve as a unit. 8. Remove bolt (9) and tube assembly (8). 9. Remove the O-ring seal from tube assembly (8). 10. The weight of the planetary group is 341 kg (750 lb). Install tooling (C), and attach a hoist as shown. 11. Remove twenty-one bolts (10) that hold the planetary group to the transmission cover. Remove the planetary group. 12. The weight of transmission cover (12) is 100 kg (220 lb). Install tooling (C) to the transmission cover, and fasten a hoist. Remove the transmission cover from tooling (A). 13. Remove suction screen cover (11) and the O-ring seal from the transmission cover. 14. Remove the suction screen from transmission cover (12). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 4/29(W) 15. Put transmission planetary group (13) in position on tooling (A). Use four bolts and nuts (14) to fasten the planetary group to tooling (A). 16. Remove retaining ring (16) from the manifold with tool (D). 17. The weight of manifold (17) is 23 kg (51 lb). Install tooling (C), and attach a hoist. Remove ten bolts (15) and manifold (17). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 5/29(W) 18. Use tool (E), and remove retaining ring (19) from manifold (17). 19. Remove bearing (18) from manifold (17). 20. The weight of first gear clutch gear (20) and housing assembly is 31 kg (68 lb). Remove first speed clutch gear and housing assembly (20). 21. Remove ten springs (22) and five dowels (23). NOTICE The discs and plates used in the individual clutches must be kept in order and with their original clutch housing. Different friction material is used for different clutches, so the discs and plates must not be mixed from one clutch to another. 22. Remove the two discs and one plate (21) that make up the second speed clutch. 23. Remove retaining ring (24), and remove housing assembly (25) from first speed clutch gear (20). 24. Remove the three discs and the two plates from first speed clutch gear (20). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 6/29(W) There is spring pressure under plate (26). To prevent possible personal injury, a press should be used to remove retainer ring (27) and to release the spring pressure slowly. 25. Put housing assembly (25) in a press as shown. Compress springs under plate (26), and remove retainer ring (27). Release spring pressure slowly, and remove plate (26) and the three spring plates under plate (26). 26. Remove piston (29) from housing assembly (25). Remove ring (30) and seal (28) from the piston. 27. Turn the housing over, and remove two seal rings (31) from carrier (32). NOTE: Carrier (32) will be destroyed if it is removed from the housing assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 7/29(W) 28. If carrier (32) is to be removed, use a hammer and chisel to break the carrier, and remove it. After the carrier is removed, remove the dowel that holds the carrier in position. 29. Use tooling (F) to hold the two pistons in clutch housing assembly (33). 30. The weight of clutch housing assembly (33) with the piston is 46 kg (101 lb). Use tooling (G), and fasten a hoist as shown. Remove clutch housing assembly (33). 31. Remove pistons (35) and (37) from clutch housing (33). 32. Remove teflon seal rings (34) and (36) from pistons (35) and (37). 33. Remove ten springs (38). 34. Remove three discs (39) and the two plates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 8/29(W) 35. Use tool (D), and remove retaining ring (40). 36. Remove gear (41) and planetary carrier (42). 37. Use a hammer and a punch, and push pins (46) into shafts (43). 38. Remove shafts (43), gears (44), and thrust washers (45) and (48) from planet carrier (42). Remove bearings (47) from gears (44). 39. Remove pins (46) from shafts (43). 40. Install small screwdrivers in the teeth around planetary carrier, location (X), to compress the retaining ring. Remove gear (49) from planetary carrier (42). 41. Put wood blocks under reverse clutch housing (52). 42. Remove two bolts (50). Use tool (H) to hold the piston in forward clutch housing (51). 43. The weight of piston and forward clutch housing (51) is 26 kg (57 lb). Use tooling (J), and attach a hoist as shown. Remove the piston and forward clutch housing (51). 44. Remove piston (53) from forward clutch housing (51). 45. Remove Teflon seal rings (54) and (55) from piston (53). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 9/29(W) 46. Remove five dowels (58) and ten springs (60). 47. Remove three discs (57), the two plates, ring gear (56) and plate assembly (59). 48. Remove three discs (61) and the two plates from reverse clutch housing assembly (52). 49. Use tool (D), and remove retaining ring (62) that holds the shaft and planetary to reverse clutch housing assembly (52). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 10/29(W) 50. The weight of output shaft (63) and the planetary assembly is 70 kg (154 lb). Use a strap and a hoist, and remove the shaft and planetary from reverse clutch housing assembly (52). 51. Remove piston (64) from reverse clutch housing assembly (52). 52. Remove Teflon seals (65) and (66) from the piston. 53. The weight of the reverse clutch housing assembly is 42 kg (92 lb). Turn the reverse clutch housing assembly over, and use tool (E) to remove snap ring (67). 54. Remove bearing (68). 55. Remove seal (70) and three seal rings (69) and (71) from the shaft and planetary assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

w 11/29(W) 56. Turn the output shaft, planetary carriers and gears over, and position them on wood blocks as shown. 57. Remove seal (72) from output shaft (63). 58. Remove seal ring (74) from the planetary carrier. 59. Remove retaining ring (73) that holds the output shaft (63) to the planetary carrier. 60. Remove output shaft (63) from the input shaft and the planetary carrier. 61. Use tool (D), and remove retaining ring (75) from output shaft assembly (63). Remove gear (76) and bearing (77) from the output shaft assembly. 62. Remove bearing (78) from output shaft (63). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 12/29(W) 63. Use tool (D), and remove retainer ring (82) that holds gear (81) in position on input shaft (80). Remove gear (81). 64. The weight of the planetary carrier is 26 kg (58 lb). Remove planetary carrier (79) from the input shaft. 65. Use tooling (K) to compress retaining ring (83). Remove gear (84) from the planetary carrier. 66. Remove retaining ring (85), and remove bearing (87) and the gear as a unit from the planetary carrier. 67. Remove bearing (87) from gear (86). 68. Use a hammer and a punch, and push pins (88) into the planetary gear shafts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2022/1/30

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com