Caterpillar Cat 538 EXCAVATOR (Prefix KBJ) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

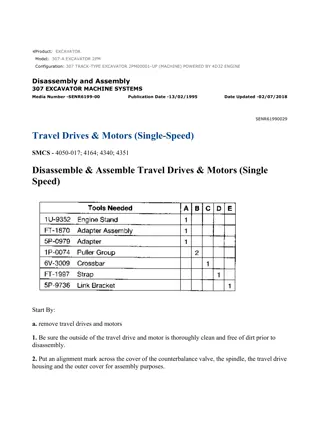

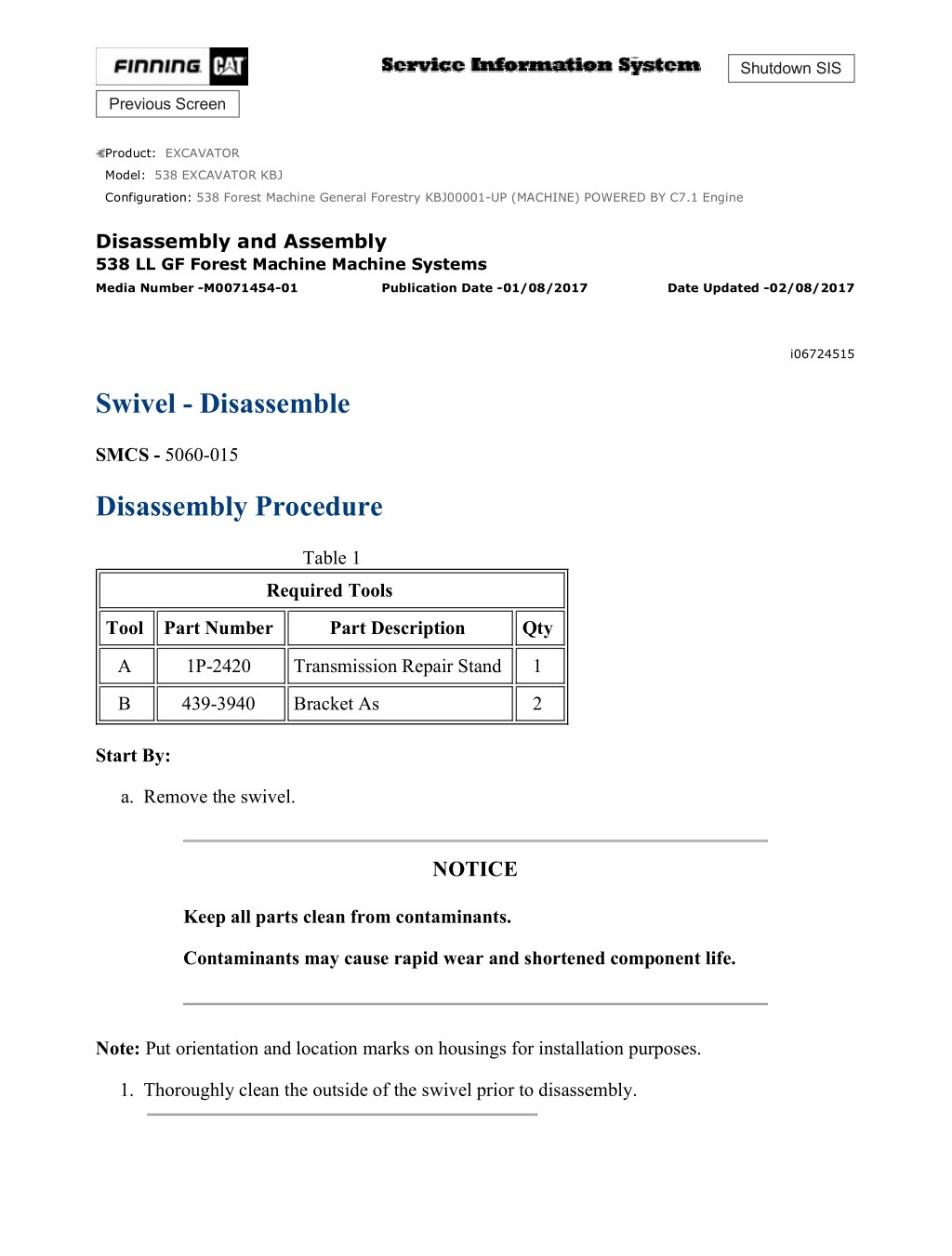

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 1/4 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 538 EXCAVATOR KBJ Configuration: 538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7.1 Engine Disassembly and Assembly 538 LL GF Forest Machine Machine Systems Media Number -M0071454-01 Publication Date -01/08/2017 Date Updated -02/08/2017 i06724515 Swivel - Disassemble SMCS - 5060-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 439-3940 Bracket As 2 Start By: a. Remove the swivel. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Put orientation and location marks on housings for installation purposes. 1. Thoroughly clean the outside of the swivel prior to disassembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 2/4 Illustration 1 g01767936 2. Attach Tooling (B) and a suitable lifting device to swivel (1). The weight of swivel (1) is approximately 496 kg (225 lb). 3. Position swivel (1) onto Tooling (A). Illustration 2 g01768234 4. Remove bolts (2) and (3). 5. Remove cover (4) from the bottom of swivel (1). Illustration 3 g01768296 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 3/4 6. Remove O-ring seal (5), bolts (6), and retainer (7) from the bottom of swivel (1). Illustration 4 g01768395 Illustration 5 g01768497 Note: Be sure that alignment marks are put on rotor (8) and housing (11) for assembly purposes. 7. Use Tooling (B) and a suitable lifting device to separate rotor (8) from housing (9). 8. Remove O-ring seal (10) (not shown) from housing (11). 9. Use Tooling (B) and a suitable lifting device to separate rotor (8) from housing (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 4/4 Illustration 6 g06092449 10. Remove seal assemblies (12) from housing (11). Illustration 7 g06092455 11. Remove seal assemblies (13) from housing (9). Copyright 1993 - 2021 Caterpillar Inc. Thu Feb 4 20:43:01 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 1/4 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 538 EXCAVATOR KBJ Configuration: 538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7.1 Engine Disassembly and Assembly 538 LL GF Forest Machine Machine Systems Media Number -M0071454-01 Publication Date -01/08/2017 Date Updated -02/08/2017 i06724539 Swivel - Assemble SMCS - 5060-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 439-3940 Bracket As 2 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Check the O-ring seals and the seals for wear or for damage. Replace the components, if necessary. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 2/4 Illustration 1 g01768813 1. Apply clean hydraulic oil to seal assemblies (12). 2. Install O-ring seal (10) and seal assemblies (12) into housing (11). Illustration 2 g01768833 3. Position housing (9) onto housing (11). Loosely install bolts (2) to secure housing (9) to housing (11). 4. Apply clean hydraulic oil to seal assemblies (13). 5. Install seal assemblies (13) into housing (9). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 3/4 Illustration 3 g01769453 6. Use two people to position housing (9) and housing (11) onto Tooling (A). The combined weight of housing (9) and housing (11) is approximately 41 kg (91 lb). Illustration 4 g01769537 7. Attach Tooling (B) and a suitable lifting device to rotor (8). The weight of rotor (8) is approximately 54 kg (119 lb). 8. Use Tooling (B) and a suitable lifting device to install rotor (8) into housing (11) and housing (9) (not shown). 9. Remove four bolts (2) (not shown). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 4/4 Illustration 5 g01768296 10. Install retainer (7), bolts (6), and O-ring seal (5) to the bottom of swivel (1). Illustration 6 g01768234 11. Install cover (4), bolts (3), and bolts (2) to the bottom of swivel (1). End By: a. Install the swivel. Copyright 1993 - 2021 Caterpillar Inc. Thu Feb 4 20:43:56 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 1/5 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 538 EXCAVATOR KBJ Configuration: 538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7.1 Engine Disassembly and Assembly 538 LL GF Forest Machine Machine Systems Media Number -M0071454-01 Publication Date -01/08/2017 Date Updated -02/08/2017 i06725205 Swing Motor - Remove and Install SMCS - 5058-010-ZW Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A FT-2674 Vacuum Cap 1 B 439-3938 Link Bracket 2 Start By: a. Release the hydraulic system pressure. Illustration 1 g01714793 1. Remove guard assembly (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 2/5 Illustration 2 g06092676 2. Remove sheet (2) and cover assembly (3). Illustration 3 g06092691 3. Remove cover assembly (4). Illustration 4 g01715574 Typical Example https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 3/5 4. Install Tooling (A) onto the hydraulic tank . Attach an air supply hose onto Tooling (A). Apply 276 to 414 kPa (40 to 60 psi) of air. This procedure will pull a vacuum on the hydraulic system. 5. Drain the swing drive oil. Refer to Operation and Maintenance Manual, "Swing Drive Oil - Change" for the correct draining and filling procedures. Illustration 5 g01715674 Note: Not all machines will require the removal of all the hose assemblies. Remove the hose assemblies that will make the removal of the swing motor easier. 6. Disconnect hose assemblies (12) and (13) at the boom side of the hose assemblies. Reposition hose assemblies (12) and (13) out of the way for more access to the swing motor. 7. Disconnect hose assemblies (6) and (7). 8. Disconnect hose assemblies (8) and (9). 9. Disconnect harness assembly (10). 10. Disconnect clip (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 4/5 Illustration 6 g01715876 11. Disconnect hose assembly (14). Illustration 7 g01715880 12. Remove bolts (16) and anti-reaction valve (17). 13. Remove bolts (15). 14. Prior to the removal of the swing motor, clean the swing motor and the area around the swing motor. Remove any loose paint around the mating surface of the swing drive and the swing motor to prevent contamination from entering the swing drive. Illustration 8 g01715956 15. Attach Tooling (B) and a suitable lifting device to swing motor (18). The weight of swing motor (18) is approximately 55 kg (120 lb). 16. Remove swing motor (18). Installation Procedure 1. Install swing motor (18) in the reverse order of removal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 1/12 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 538 EXCAVATOR KBJ Configuration: 538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7.1 Engine Disassembly and Assembly 538 LL GF Forest Machine Machine Systems Media Number -M0071454-01 Publication Date -01/08/2017 Date Updated -02/08/2017 i06726429 Swing Motor - Disassemble SMCS - 5058-015-ZW Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 8T-0651 Bolts 2 A 8T-4167 Hard Washers 2 B 1P-1859 Retaining Ring Pliers 1 C 9S-9152 Bearing Puller Gp 1 1P-0074 Slide Hammer Puller 1 5F-7344 Puller Block 1 D 5P-4750 Adjusting Screw 1 7S-7786 Puller Leg 2 Start By: a. Remove the swing motor. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 2/12 Illustration 1 g00704611 1. If necessary, remove bolts (2) and anti-reaction valve (3) from head (1). 2. Remove mounting bolts (4). Illustration 2 g00704621 3. Remove dipstick tube (5) and breather tube (6) from motor housing (7). Illustration 3 g00704704 4. Remove relief valves (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 3/12 Illustration 4 g00704710 5. Remove O-ring seals (10), (12), and (13). 6. Remove backup rings (9) and (11). Illustration 5 g00704719 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 4/12 7. Remove bolts (14) and the head. Illustration 6 g00704734 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 8. Remove plug (18), O-ring seal (17), spring (16), and spool valve (15) from the head. Repeat for the other side. Illustration 7 g00704741 9. Remove adapter (19), fitting (20), and plugs (21). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 5/12 Illustration 8 g00704743 10. Remove O-ring seal (22) from plug (21). Illustration 9 g00704749 11. Remove O-ring seals (23) and (24) from fittings (19) and (20). Illustration 10 g00704754 12. Remove O-ring seal (25). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 6/12 Illustration 11 g00704771 13. Remove spring pins (26) and bearing (27). Illustration 12 g00704796 14. Remove springs (28) and port plate (29). Illustration 13 g01021864 Typical Example 15. Install Tooling (A) and apply air pressure to unseat the piston. Note: Use air pressure to avoid damage to the piston. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 7/12 Illustration 14 g01021875 16. Remove piston (30). Illustration 15 g01022038 Typical Example 17. Remove plates (31). Illustration 16 g01021889 Typical Example 18. Remove barrel (32) and the pistons as an assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 8/12 Illustration 17 g01021898 19. Mark pistons (33). 20. Remove pistons (33) from barrel (32). Illustration 18 g01021903 21. Remove pistons (33) from plates (34) and (35). Illustration 19 g01021909 22. Separate plates (34) and (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 9/12 Illustration 20 g01021919 Typical Example 23. Remove O-ring seals (36) and (36a) from the motor housing. Illustration 21 g00705209 24. Remove swashplate (37). Illustration 22 g00705222 25. Use Tooling (B) to remove retaining ring (38) from shaft (39). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY ... 10/12 Illustration 23 g00705258 26. Remove shaft (39). Illustration 24 g00705277 27. Use a suitable press and Tooling (C) to remove bearing race (40). Illustration 25 g00705284 28. Use a suitable press and Tooling (C) to remove bearing race (41). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY ... 11/12 Illustration 26 g01022013 Typical Example Illustration 27 g00705295 29. Use Tooling (D) to remove bearing (42). Illustration 28 g00705441 30. Remove lip seal (43). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY ... 12/12 Illustration 29 g00705442 31. Remove fitting (44). Illustration 30 g00705445 32. Remove O-ring seal (45) from fitting (44). Copyright 1993 - 2021 Caterpillar Inc. Thu Feb 4 20:45:48 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 1/13 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 538 EXCAVATOR KBJ Configuration: 538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7.1 Engine Disassembly and Assembly 538 LL GF Forest Machine Machine Systems Media Number -M0071454-01 Publication Date -01/08/2017 Date Updated -02/08/2017 i06727706 Swing Motor - Assemble SMCS - 5058-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty B 1P-1859 Retaining Ring Pliers 1 E 1P-0510 Driver Group 1 F 369-9451 Grease - Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Note: O-ring seals, gaskets, and seals should always be replaced. A used O-ring seal may not have the same sealing properties as a new O-ring seal. Use Tooling (F) during the assembly procedure. Note: Apply a light film of clean hydraulic oil to all components before assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 2/13 Illustration 1 g00705445 1. Install O-ring seal (45) onto fitting (44). Illustration 2 g00705442 2. Install fitting (44). Illustration 3 g00705441 3. Lubricate lip seal (43) with clean hydraulic oil. Install lip seal (43) with the lip toward the inside of the motor housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 3/13 Illustration 4 g01022013 Typical Example Illustration 5 g01287176 4. Use Tooling (E) to install bearing (42). Illustration 6 g00705595 5. Raise the temperature of bearing race (41). Install bearing race (41). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 4/13 Illustration 7 g00705592 6. Raise the temperature of bearing race (40). Install bearing race (40). Illustration 8 g00705597 Illustration 9 g00705258 7. Install shrink wrap tubing onto shaft (39). The shrink wrap tubing will protect the seal during installation of shaft (39). 8. Install shaft (39). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

538 Forest Machine General Forestry KBJ00001-UP (MACHINE) POWERED BY C7... 5/13 Illustration 10 g00705602 9. Use Tooling (B) to install retaining ring (38) onto shaft (39). Remove the shrink wrap tubing. Illustration 11 g00705209 10. Install swashplate (37). Illustration 12 g01021919 Typical Example 11. Install O-ring seals (36) and (36a) into the motor housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/2/4

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com