Caterpillar Cat 317 and 317N Excavator (Prefix 9SR) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

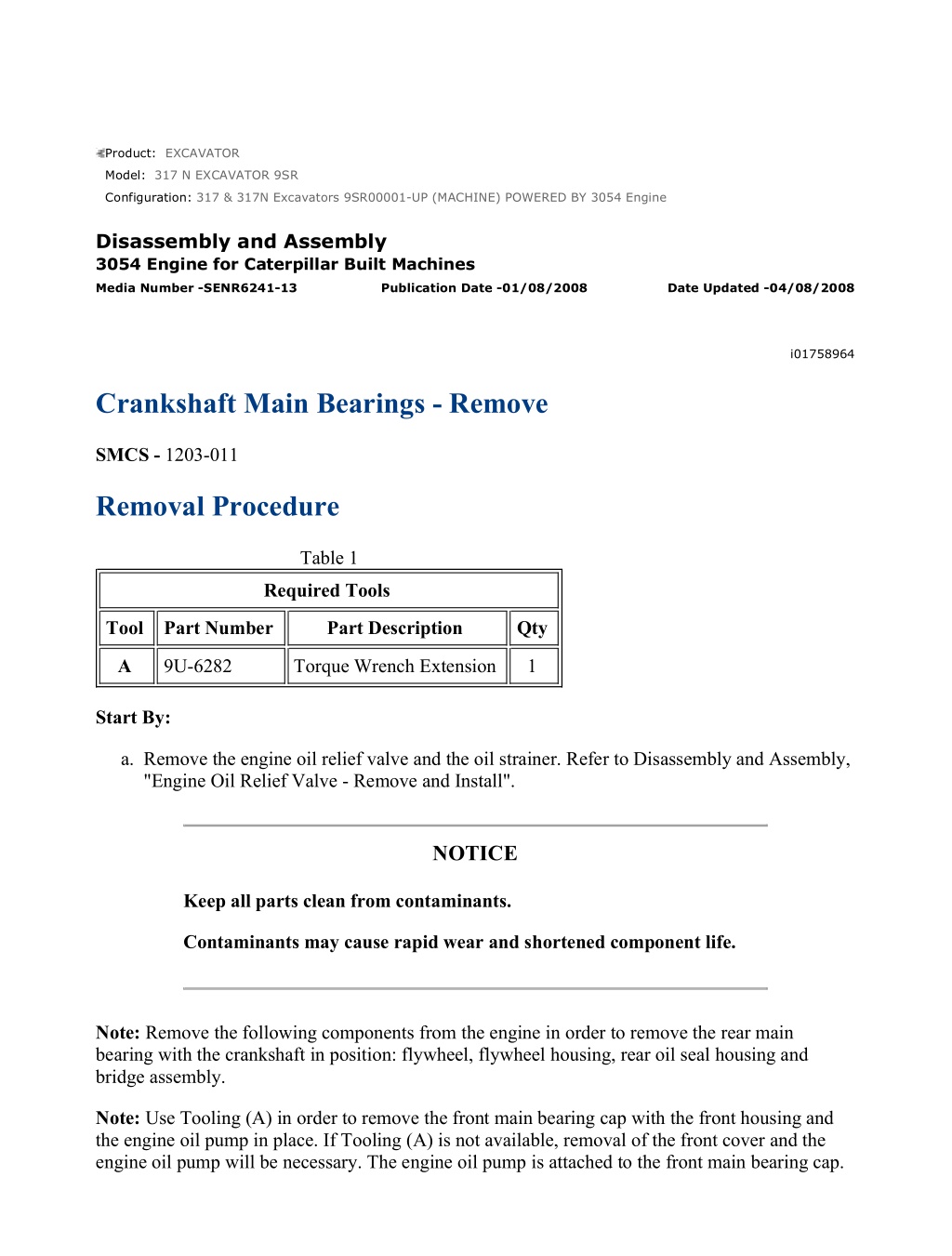

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/3 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01758964 Crankshaft Main Bearings - Remove SMCS - 1203-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 9U-6282 Torque Wrench Extension 1 Start By: a. Remove the engine oil relief valve and the oil strainer. Refer to Disassembly and Assembly, "Engine Oil Relief Valve - Remove and Install". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: Remove the following components from the engine in order to remove the rear main bearing with the crankshaft in position: flywheel, flywheel housing, rear oil seal housing and bridge assembly. Note: Use Tooling (A) in order to remove the front main bearing cap with the front housing and the engine oil pump in place. If Tooling (A) is not available, removal of the front cover and the engine oil pump will be necessary. The engine oil pump is attached to the front main bearing cap. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/3 Removal of the bolts is not possible with a socket. Refer to Disassembly and Assembly, "Engine Oil Pump - Remove". 1. Remove all necessary components in order to gain access to the specific main bearing cap. 2. Make sure that the main bearing cap is marked for the location and direction for installation. The main bearings and the main bearing caps must be installed in the same location. Illustration 1 g00554537 3. Remove two bolts (1) and main bearing cap (2). Illustration 2 g00554539 4. Remove lower main bearing (3) from main bearing cap (2). Keep the respective main bearing and the main bearing cap together for proper installation. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 3/3 Illustration 3 g00554540 5. Push upper main bearing (4) from the opposite side of the bearing tab with a suitable tool. Carefully rotate the crankshaft while you push on the bearing. Remove upper main bearing (4) from the cylinder block. Keep the upper bearing halves together in order to ensure proper installation. 6. Repeat Steps 1 through 5 for the remaining main bearings. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/4 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01758965 Crankshaft Main Bearings - Install SMCS - 1203-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A(1) 9U-6282 Torque Wrench Extension 1 B 8T-5096 Dial Indicator 1 (1)Tooling (A) must be used in order to install the front main bearing cap with the front housing and the engine oil pump in place. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/4 Illustration 1 g00554540 1. Clean upper main bearing (4) and lubricate the bearing surface with clean engine oil. Note: Ensure that the upper halves of the main bearings are installed so that the bearing tabs fit into the notch in the cylinder block. NOTICE Only the upper half of the main bearing has lubrication holes. Make sure the upper half of the main bearing is installed correctly in the cylinder block to ensure proper lubrication. 2. Slide upper main bearing (4) into position between the crankshaft journal and the cylinder block. Illustration 2 g00554539 3. Clean main bearing cap (2) and lower main bearing (3). Lubricate the bearing surface of lower main bearing (3) with clean engine oil. Note: Ensure that the lower halves of the main bearings are installed so that the bearing tabs fit into the notch in the main bearing caps. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 3/4 4. Install lower main bearing (3) in main bearing cap (2). Illustration 3 g00554537 5. Make sure that the bearing tabs on both halves of the main bearings are located on the same side. Install main bearing caps (2). 6. Lubricate the threads of bolts (1) with clean engine oil. 7. Install bolts (1). Tighten bolts (1) to a torque of 250 N m (185 lb ft). Use Tooling (A) to tighten the bolts for the front main bearing cap. 8. Repeat Steps 1 through 7 for the remaining main bearings. 9. Rotate the crankshaft in order to ensure that the crankshaft turns freely. Illustration 4 g00555578 Typical example 10. Check the crankshaft end play. Use a prybar to move the crankshaft toward the rear of the engine. Install Tooling (B) and zero the dial indicator. Move the crankshaft with the prybar toward the front of the engine. Measure the crankshaft end play. The maximum permissible crankshaft end play is 0.51 mm (0.020 inch). Note: If the crankshaft was not removed for the rear main bearing removal, the following components must be installed: bridge assembly, rear oil seal housing, flywheel housing and flywheel. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 4/4 End By: a. Install the engine oil relief valve and the oil strainer. Refer to Disassembly and Assembly, "Engine Oil Relief Valve - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/4 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01645907 Crankshaft - Remove SMCS - 1202-011 Removal Procedure Start By: A. Remove the fuel injection pump. Refer to Disassembly and Assembly, "Fuel Injection Pump - Remove". B. Remove the engine oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Remove". C. Remove the front housing. Refer to Disassembly and Assembly, "Housing (Front) - Remove". D. Remove the flywheel housing. Refer to Disassembly and Assembly, "Flywheel Housing - Remove and Install". E. Remove the housing for the crankshaft rear seal. Refer to Disassembly and Assembly, "Crankshaft Rear Seal - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/4 Illustration 1 g00541252 1. Remove two socket head bolts (1) that hold bridge (2) in position. 2. Remove bridge (2) from the cylinder block. Illustration 2 g00541253 Note: Inspect the main bearing caps and the connecting rod caps for the proper identification marks. The identification marks should give the location and the direction of the bearings in the engine. 3. Remove ten main bearing cap bolts (3) from the main bearing caps. 4. Remove five main bearing caps (4) from the cylinder block. 5. Remove the lower main bearings and the lower thrust washers. Keep the lower main bearings with the respective main bearing caps. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 3/4 Illustration 3 g00541254 Note: The connecting rod caps can be held on the connecting rod with two bolts and two nuts. The connecting rod caps can also be held on the connecting rod with two bolts that are threaded into the connecting rod. 6. Remove eight nuts (5) from the connecting rod caps. 7. Remove four connecting rod caps (6) from the connecting rods. 8. Remove the bearings from connecting rod caps (6). Keep the connecting rod bearings with the respective connecting rod cap. NOTICE Do not allow the connecting rods to strike the piston cooling jets. Damage or misalignment may occur. 9. Push the piston assemblies into the cylinder bores. Illustration 4 g00541256 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 4/4 10. Attach lifting straps and a suitable lifting device to crankshaft (7) . 11. Lift crankshaft (7) out of the cylinder block. The weight of the crankshaft is 29 kg (65 lb). Do not scratch any of the finished surfaces on the crankshaft. Illustration 5 g00541257 12. Remove upper main bearings (8) and upper thrust washers (9) from the cylinder block. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/5 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i04990490 Crankshaft - Install SMCS - 1202-012 Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. 1. Ensure that all of the lubrication passages are clean and free of debris. 2. Clean the seat for the main bearing in the cylinder block and clean the upper main bearings. Illustration 1 g00541257 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/5 3. Install upper main bearings (8) with the location tabs in the correct position in the cylinder block. Lubricate upper main bearings (8) with clean engine oil. Illustration 2 g00541256 4. Ensure that the main bearing journals of crankshaft (7) are clean. Attach lifting straps and a suitable lifting device in order to position the crankshaft in the cylinder block. 5. Clean upper thrust washers and lubricate upper thrust washers (9) . Place upper thrust washers (9) in the cylinder block on both sides of the center main bearing. NOTICE Ensure that the slotted sides of the thrust washers are toward the crankshaft. 6. Clean the lower main bearings. Install the lower main bearings in the main bearing caps with the location tabs in the correct position. Lubricate the lower main bearing caps with clean engine oil. 7. Clean the lower thrust washers and lubricate the lower thrust washers. Place the lower thrust washers in the cylinder block. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 3/5 Illustration 3 g00541253 8. Ensure that the dowels for main bearing caps (4) are in the correct position in the main bearing caps or in the cylinder block. Install main bearing caps (4) in the position that is marked during the removal process. All of the location tabs on the main bearings should be on the same side. The serial number that is stamped on the main bearing cap should match the number that is stamped on the bottom face of the cylinder block. Note: The connecting rod caps can be held on the connecting rod with two bolts and two nuts. The connecting rod caps can also be held on the connecting rod with two bolts that are threaded into the connecting rod. 9. Install bolts (3) in the main bearing caps. Tighten the bolts to a torque of 265 N m (196 lb ft). Illustration 4 g00541254 10. Install connecting rod caps (6) and connecting rod cap bolts (5) . Tighten the bolts to a torque of 155 N m (115 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 4/5 Illustration 5 g00541252 11. Clean the bridge and the face of the cylinder block. Apply a thin bead of Loctite 596 on the corners of the seat for the bridge. Also apply the sealant around the thread holes in the seat for the bridge. Use the following steps when you apply the Loctite 596 to the cylinder block and the bridge. a. Apply a 3.0 mm (0.12 inch) bead of Loctite 596 along the corner of the top recess in the cylinder block. Illustration 6 g00541499 b. Install bridge (2) and the rubber seals, if equipped. The rubber seals will sit higher than the bridge when the seals are correctly installed. Use a straight edge to line up the bridge with the face of the cylinder block. Tighten socket head bolts (1) to a torque of 16 N m (12 lb ft). Tighten the bolts evenly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 5/5 Illustration 7 g00541498 c. When the bridge is positioned and the socket head bolts have been tightened, inject Loctite 596 in the groove that are at each end of the bridge. The groove must be completely filled. d. When the gasket for the oil pan is removed, damage may occur to the existing seal in the grooves of the bridge. If the seal is damaged, apply a sufficient amount of Loctite 596 in order to fill the grooves. Note: Most of the current engines have setscrews that fasten the oil pan to the bridge. The threads of the setscrews have a sealant that is applied by the manufacturer. When the setscrews are installed, ensure that the threads of the socket head bolts and the bridge are clean. Also apply 9S-3263 Thread Lock Compound to the threads of the setscrews. Follow the same process when studs are used instead of the setscrews. End By: a. Install the housing for the crankshaft rear seal. Refer to Disassembly and Assembly, "Crankshaft - Install". b. Install the flywheel housing. Refer to Disassembly and Assembly, "Flywheel Housing - Remove and Install". c. Install the oil pump. Refer to Disassembly and Assembly, "Engine Oil Pump - Install". d. Install the fuel injection pump. Refer to Disassembly and Assembly, "Fuel Injection Pump - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/3 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01758909 Crankshaft Gear - Remove and Install SMCS - 1204-010-GE Removal Procedure Start By: a. Remove the fan. Refer to Disassembly and Assembly, "Fan - Remove and Install". b. Remove the front cover. Refer to Disassembly and Assembly, "Front Cover - Remove". Note: Rotate the crankshaft until the timing marks on the crankshaft gear, the camshaft gear, and the idler gear are aligned. Illustration 1 g00556563 Typical example 1. Remove bolts (1) from idler gear (2). 2. Remove idler gear (2) and spacer (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/3 Illustration 2 g00556666 Typical example 3. Use a suitable puller to remove crankshaft gear (4) from crankshaft (5). Note: Do not use a flame on the crankshaft gear for removal purposes. Note: Be careful not to scratch the surface of the bearing journal. Installation Procedure Illustration 3 g00556666 Typical example 1. Heat crankshaft gear (4) in an oven to 180 C (356 F). 2. Install crankshaft gear (4) on crankshaft (5) with the timing marks toward the front. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 3/3 Illustration 4 g00556563 Typical example 3. Install spacer (3) and idler gear (2). 4. Install bolts (1) on idler gear (2). Tighten the bolts to a torque of 44 N m (32 lb ft). Note: Ensure that the timing marks on the crankshaft gear, the camshaft gear, and the idler gear are aligned. 5. Refer to Disassembly and Assembly, "Gear Group (Front) - Install" for the correct alignment of the idler gear. End By: a. Install the front cover. Refer to Disassembly and Assembly, "Front Cover - Install". b. Install the fan. Refer to Disassembly and Assembly, "Fan - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/3 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i05977048 Bearing Clearance - Check SMCS - 1203-535; 1219-535 Measurement Procedure Table 1 Required Tools Tool Part Number Part Description Qty Plastic Gauge (Green) 0.025 to 0.076 mm (0.001 to 0.003 inch) 198-9142 1 Plastic Gauge (Red) 0.051 to 0.152 mm (0.002 to 0.006 inch) 198-9143 1 A Plastic Gauge (Blue) 0.102 to 0.229 mm (0.004 to 0.009 inch) 198-9144 1 Plastic Gauge (Yellow) 0.230 to 0.510 mm (0.009 to 0.020 inch) 198-9145 1 Note: Plastic gauge may not be necessary when the engine is in the chassis. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/3 Note: Cat does not recommend the checking of the actual bearing clearances particularly on small engines. This is because of the possibility of obtaining inaccurate results and the possibility of damaging the bearing or the journal surfaces. Each Cat engine bearing is quality checked for specific wall thickness. Note: The measurements should be within specifications and the correct bearings should be used. If the crankshaft journals and the bores for the block and the rods were measured during disassembly, no further checks are necessary. However, if the technician still wants to measure the bearing clearances, Tooling (A) is an acceptable method. Tooling (A) is less accurate on journals with small diameters if clearances are less than 0.10 mm (0.004 inch). NOTICE Lead wire, shim stock or a dial bore gauge can damage the bearing surfaces. The technician must be very careful to use Tooling (A) correctly. The following points must be remembered: Ensure that the backs of the bearings and the bores are clean and dry. Ensure that the bearing locking tabs are properly seated in the tab grooves. The crankshaft must be free of oil at the contact points of Tooling (A). 1. Put a piece of Tooling (A) on the crown of the bearing that is in the cap. Note: Do not allow Tooling (A) to extend over the edge of the bearing. 2. Use the correct torque-turn specifications in order to install the bearing cap. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed. Note: Do not turn the crankshaft when Tooling (A) is installed. 3. Carefully remove the cap, but do not remove Tooling (A). Measure the width of Tooling (A) while Tooling (A) is in the bearing cap or on the crankshaft journal. Refer to Illustration 1. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 3/3 Illustration 1 g01152855 Typical Example 4. Remove all of Tooling (A) before you install the bearing cap. Note: When Tooling (A) is used, the readings can sometimes be unclear. For example, all parts of Tooling (A) are not the same width. Measure the major width in order to ensure that the parts are within the specification range. Refer to Specifications Manual, "Connecting Rod Bearing Journal" and Specifications Manual, "Main Bearing Journal" for the correct clearances. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/2 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01758956 V-Belts - Remove and Install SMCS - 1357-010 Removal Procedure Illustration 1 g00540870 Typical example 1. Loosen all of the bolts that fasten the fan guard assembly to the fan shroud. Remove fan guard assembly (1) from the fan shroud. 2. Loosen bolts (2) and slide alternator (3) toward the engine. 3. Maneuver V-belts (4) around the fan and remove the V-belts. Note: Never replace one V-belt. Always replace sets of V-belts, if equipped. Installation Procedure https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/2 Illustration 2 g00540870 Typical example 1. Install V-belts (4) behind the fan and on the correct pulleys. 2. Slide alternator (3) away from the engine. Tighten bolts (2) and check the belt tension. Refer to Specifications , RENR2401, "Belt Tension Chart" for the correct belt tension. Note: If the V-belt cannot be checked with a gauge, press on the V-belt at the center of the longest free length in order to check the deflection. Under a moderate amount of pressure, the V-belt should have a deflection of 10.0 mm (0.40 inch). 3. Put fan guard assembly (1) in position on the fan shroud. Install the bolts that fasten the fan guard assembly to the fan shroud. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/2 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01228282 Fan - Remove and Install SMCS - 1356-010 Removal Procedure Illustration 1 g00542576 1. Remove four bolts (1) . 2. Remove fan (2) . 3. Remove extension (3) that is behind the fan. 4. Remove the fan pulley, if necessary. Installation Procedure https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 2/2 Illustration 2 g00542576 1. Inspect the condition of the fan pulley. Replace the fan pulley, if necessary. 2. Install extension (3) behind the fan. 3. Install fan (2) . 4. Install four bolts (1) . Reference: Refer to Specifications, "Fan Drive" in order to tighten the bolts to the proper torque. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/2 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01187575 Fan Drive - Remove SMCS - 1359-011 Removal Procedure Start By: A. Remove the fan. Refer to Disassembly and Assembly, "Fan - Remove and Install". Illustration 1 g00636125 Typical example 1. Remove the four bolts (1) from fan drive housing (2) . 2. Remove the fan drive (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine(SE... 1/2 Product: EXCAVATOR Model: 317 N EXCAVATOR 9SR Configuration: 317 & 317N Excavators 9SR00001-UP (MACHINE) POWERED BY 3054 Engine Disassembly and Assembly 3054 Engine for Caterpillar Built Machines Media Number -SENR6241-13 Publication Date -01/08/2008 Date Updated -04/08/2008 i01187598 Fan Drive - Install SMCS - 1359-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0510 Driver Group 1 Illustration 1 g00636125 Typical example 1. Install the fan drive (2) . 2. Use Tool (A) to install fan drive housing (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/1/9

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com