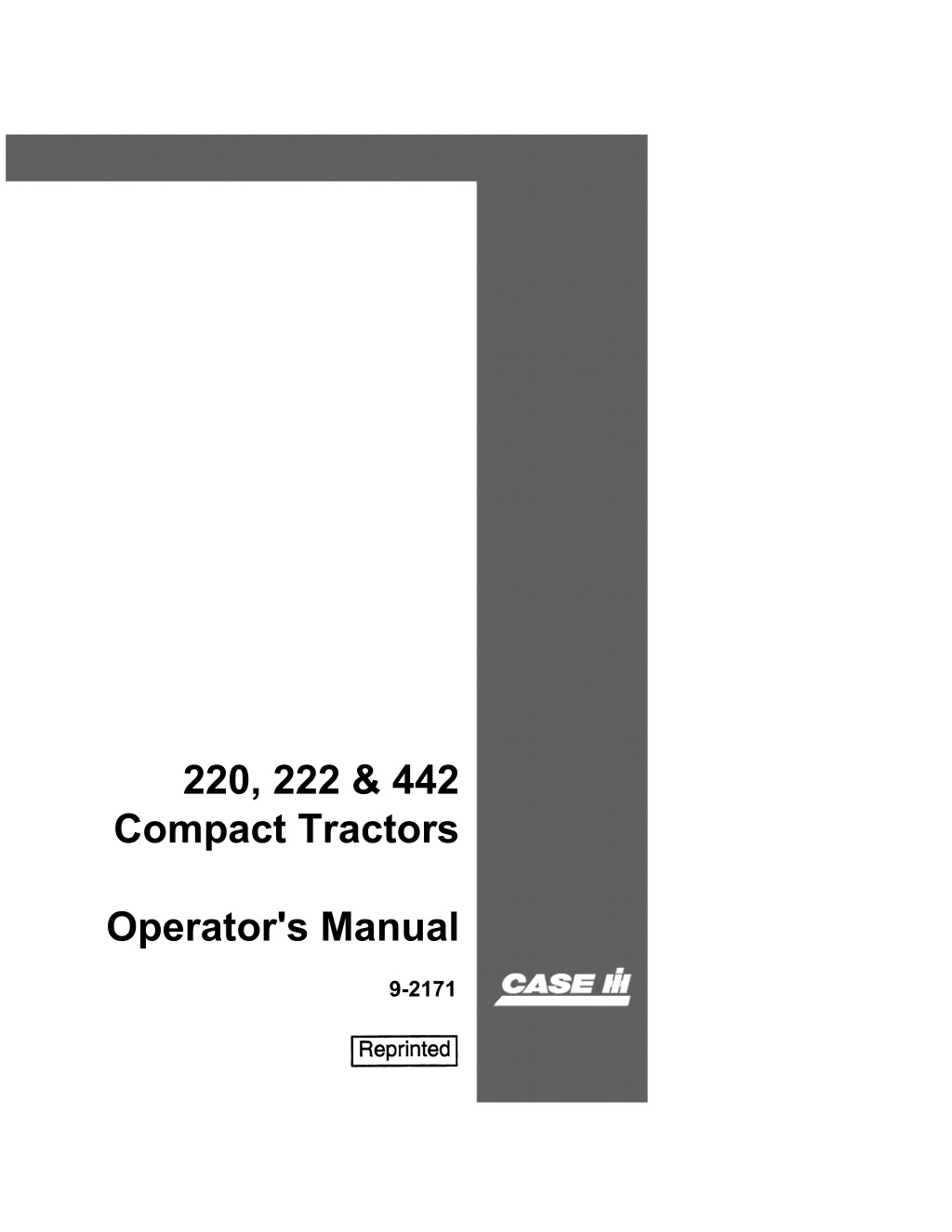

Case IH 220 222 442 Compact Tractors Operator’s Manual Instant Download (Publication No.9-2171)

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

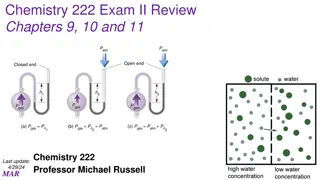

220, 222 & 442 Compact Tractors Operator's Manual 9-2171

6 THIS SAFETY ALERT SYMBOL INDICATES IMPORTANT SAFETY MESSAGES IN THIS MANUAL. WHEN YOU SEE THIS SYMBOL, , CAREFULL Y READ THE MESSAGE THAT FOLLOWS AND BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY OR DEA TH. M171B If Safety Decals on this machine use the words Danger, Warning or Caution, which are defined as follows: DANGER: Indicates an immediate hazardous situation which if not avoided, will result in death or serious injury. The color associated with Danger is RED. WARNING: Indicates an potentially hazardous situation which if not avoided, will result in serious injury. The color associated with Warning is ORANGE. CAUTION: Indicates an potentially hazardous situation which if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices. The color associated with Caution is YELLOW. If Safety Decals on this machine are ISO two panel Pictorial, decals are defined as follows: The first panel indicates the nature of the hazard. The second panel indicates the appropriate avoidance of the hazard. Background color is YELLOW.IC'\ 6 WARNING IMPROPER OPERATION OF THIS MACHINE CAN CAUSE INJURY OR DEATH. BEFORE USING THIS MACHINE, MAKE CERTAIN THAT EVERY OPERATOR: Prohibition symbols such as \y X and 8 if used, are RED. Is instructed in safe and proper use of the machine. Reads and understands the Manual(s) pertaining to the machine. Reads and understands ALL Safety Decals on the machine. Clears the area of other persons. Learns and practices safe use of machine controls in a safe, clear area before operating this machine on a job site. It is your responsibility to observe pertinent laws and regulations and follow Case Corporation instructions on machine operation and maintenance. Bur 0-00000 2001 Case Corporation March, 1995 (Revised October, 1997) CASE and IH are registered trade marks of Case Corporation

220, 222 & 442 Compact Tractors

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

NOTICE At the time your Case Dealer delivers your new tractor, he will acquaint you with .its operation and maintenance as outlined in th "Delivery Procedure and Warranty Registration". When your Deale .. has completed these instructions, he will ask you to sign the report and will then hand you a copy for your records. NOTE The "Delivery Procedure and Warranty Registration" also contains a record of the Pre-Delivery Checkup which your Dealer made on your tractor. A factory completed Quality Audit just prior to crating is further assurance that your new tractor has been manu- factured and tested to the highest pos- sible standards and is ready to provide you with long, trouble free service. The inspector's copy of the Quality Assurance Audit Procedure is packed with the trac- tor. APTER DELIVERY CHECKUP The Authorized Case Dealer from whom you purchased your newtractorwill perform the "After Delivery Checkup" outlined on the following page, if you will arrange to bring your tractor to his Ser- vice Shop within - - - 60 days after date of delivery or 100 hours of operation (whichever occurs first). NOTE The only charge your dealer will make for this inspection will be for Oil, filter, or other accessories.

ArTER DELIVERY CHECKUP (OWlUtZ". Na.me) (De.lerehip) Tractor has been operated ........ days TRACTOR o o o 0 Cooling system engine and heat exchanger fins. o Crankcase oil (change oil if necessary). o Oil level in hydraulic system reservoir. o Oil level in transmission. o Lubricate all pressure fit- tings. o o o Check "free play." just if necessary. Check front wheel toe-in. 0 Battery, starter-generator and lights. 0 Check operation of all instru- ments and levers. Return to neutral function. Check operation of brake. Check Speed Control Lever for proper "Neutral" and full valve spool travel. o Check tire pressure. o Tighten cylinder head and ad- just tappets. o o o engine speed and low idle speed. D Tighten all hydraUlic line con- nections. o Tighten all bolts (including rims). DEALER: Question purchaser carefully concerning his experience with tractor and answer any questions concerning main- tenance or operation that are not clear to him. Check air cleaner. Check tension of all belts. Lubricate steering gears. Check ignition timing. Check spark plug. Ad- Check full governed no load o Checkup .................................................................. . Performed by Signed ....................................................................... . D.aler Origiaal-De.ler D.pUcat_Le .... in Opel'4ton Manllal for Pureha .. r Signed ...................................................................... . C".tOJll..r

TO THE PURCHASER OF A CASE TRACTOR The care you give your new Case Tractor will greatly determine the satisfaction and service life you will obtain from it. Use this manual as your guide. By observing the instructions and suggestions in this manual, your Case Tractor will serve you well for many years. As an Authorized Case Dealer, we stock Genuine Case Parts, which are manufactured with the same precision and skill as the original equipment. Our factory trained staff is kept well informed "on the best methods of servicing Case equipment and is ready and able to help you. Should you require additional aid or information, contact us. HI FOLKS!-I'm Sammy Safety. Look for me to point out important Safety Precautions To insure efficient and prompt service, please furnish us with the Model, Serial, Engine Model Number and Engine Specification Num- ber of your Tractor in all correspondence or contacts. 4

SERIAL NUMBER When ordering parts from your Authorized Case Dealer and in all contacts or correspondence with your dealer relative to the tractor always specify the Serial, Model and Engine Numbers of your tractor. The Tractor Model and Serial Numbers are stamped on the number plate located on the instrument panel, Figure 5. The En- gine, Model, Serial and Engine Specification Numbers are stamped on a plate fastened to the right hand side of the engine, Figure 6. TRACTOR MODEL AND SERIAL NUMBER ENGINE MODEL, SERIAL AND SPECIFICATION NUMBER Figure 5. Figure 6. NOTE The terms ''Right Hand" and "Left Hand" whenever used in this manual apply to the tractor when facing in the direction the tractor will move in forward operation. For reference, fill in the Serial Number,ModelNumber and En- gine Numbers of your tractor in the spaces provided below. Tractor Model Number Tractor Serial Number Engine Model Number Engine Serial Number Engine Specification Number ______ _ 7

SPECIFICATIONS General 222 220 AND 442 Kohler K301A 4 1 3-3/8 in. 3-1/4 in. 29.07 cu. in.. 12 HP 6 to 1 3500 RPM 3600 RPM 1000 RPM .010 ,in. .020 in. Type _________________________________ Kohler Model ________________________________ K241A Cycle ________________________________ 4 Cylinders ____________________________ 1 Cylinder Bore ________________________ 3-1/4 in. Stroke ________________________________ 2-7/8 in. Piston Displacement ___________________ 23.9 cu. in. Horsepower __________________________ 10 HP Compression Ratio ____________________ 6 to 1 Full Load Speed _______________________ 3500 RPM No Load Speed ________________________ 3600 RPM Idle Speed ____________________________ 1000 RPM Valve Clearance Cold {lntakeL __________ .010 in. Valve Clearance Cold (Exhaust) _________ .020 in. Piston and Connecting Rod Piston ____________________________________________ Aluminum ________________________________________ 2 __________________________________________________ 1 Connecting Rod ____________________________________ Aluminum C o m p r e s s i o n R ~ s O i I R ~ s Fuel System Carburetor ____________________________________ 1" SAE Flange F1lter Screen _____________________________ In tank outlet fitting Fuel Tank Capacity ___________________________________ 8 Quarts Ignition System Breaker Point Gap ____________________________________ .020 in. Ignition Timing _____________________________________ SP Mark Spark Plug ______________________ Prestolite 14 L7 or equivalent Thread ______________________________________________ 14 MM Gap ___________________________________________________ .025" Cooling System Blower------------------- Forced air with baffles directing air around finned cylinder and head area 8

Hydraulic System Reservoir------------------- Independent reservoir with built .. in filter screen Reservoir Capacity--------------______________________ 5 Quarts Electrical System Type of System-------------------------- 12 Volt, Negative Ground Battery ---------------------------------------------Autolite LU7 Starter-Generator ---------------------------------------- 12 Volt Voltage Regulator --------------------------------Automatic Type Headlights ----------------------------------------------- 12 Volt Brake Type------------------------.Mechanical Contracting Band, with the drum shaft driven from transmission differential. Includes parking lock. Transmission Type------------------------------------------------ Dual Range Speed Ranges----------------------------------------Highand Low Differential---------------------------Automotive Type Bevel Gear Oil Capacity ------------------------------------------- 3 Quarts SPEED RANGE FORWARD o to 3.0 MPH o to 7.3 MPH o to 3.2 MPH o to 7.7 MPH REVERSE o to 3.0 MPH o to 7.3 MPH o to 3.2 MPH o to 7.7 MPH 220 AND Low 222 High Low High 442 WHEELS AND TIRES Tire Size PLY Type FRONT High Flotation REAR High Flotation High Flotation PSI Recommended 8 Max. 14 6.50-8 2 8.50-12 8.00-16 2 2 8 8 10 14 , . - 9 .- -

. Overall Measurements 220 & 222 442 70" 65" OVerall Length A 46" 46" Wheel Base B 43-1/2" 40" OVerall Height C 35-1/2" 38-1/2" Hood Height - Rear Minimum Ground Clearance at Gear Case Rear Wheel Tread D 7-1/8" 11" E 27-3/4" 31-1/2" 28-3/4" Front Wheel Tread 33-1/2" 41" OVerall Width 37" 715 Ibs. 7701bs. Shipping Weight 10

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Figure 7 NEVER FILL THE FUEL TANK WHEN THE ENGINE IS RUNNING OR WHEN NEAR AN OPEN FLAME. DO NOT SMOKE WHEN WORKING NEAR IN- FLAMMABLE FUELS. FOR ADDED SAFETY THE FUEL TANK IS LOCATED UNDER THE HINGED SEAT AWAY FROM THE ELECTRICAL AND ENGINE COMPONENTS. SEE FIGURE 7. GASOLINE Kohler Gasoline Engines are designed to operate on REGULAR GRADE gasoline having a minimum research method rating of 90.7 Octane. This will give full power and economy together with long engine life and low maintenance cost. The average octane number ratings for regular grade gasoline (March 1967). Motor Method -------.. ----------------- 86.2 Octane Number Research Method-----.. _ .. ------_ .. -------- 94.2 Octane Number These two Octane ratings are used to define the anti-knock quality of gasoline. It has become common practice in the Petroleum Industry to refer only to the RESEARCH METHOD RATING. When only one Octane rating is given for gasoline and the rating method is not specified, it can be assumed to be the Research Method Rating. 11

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com