Analysis of Automotive Paint Smears Using Charpy Impact Tester

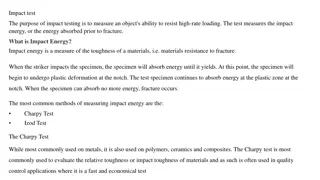

The study focuses on developing a procedure utilizing a Charpy impact tester to generate and analyze automotive paint smears, particularly in crime scene investigations. These paint smears are complex mixtures of various paint layers, making analysis challenging. The impact-induced smearing process mimics real collision conditions. The Charpy impact tester measures the energy absorbed by fractured specimens, aiding in paint smear analysis.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Attenuated Total Reflection Infrared Microscopy and Charpy Impact Tester for Analysis of Automotive Paint Smears Barry K. Lavine and Undugodage Perera, Department of Chemistry, Oklahoma State University, Stillwater, Oklahoma 74078 Kaan Kalkan and Linqi Zhang,, Department of Mechanical Engineering, Oklahoma State University, Stillwater, OK 74078

Modern Automotive Paint Systems Modern automotive paint systems (since 2000) consist of multiple layers of paint: thick clear coat over a thin color coat which in turn is over one or more thin undercoats (surfacer-primer and e-coat layer).

Problem Statement Paint Smears are often recovered from a crime scene where damage to a vehicle and/or injury or death to a pedestrian has occurred. Extracting lead information from a paint smear is problematic as there are no reference materials available in paint database to generate hit- lists of potential suspect vehicles. A procedure based on a Charpy impact tester is currently being developed to generate paint smears due to paint transfer from an automotive substrate to any surface of interest under conditions simulating those of a real collision.

Paint Smears Automotive paint smears are difficult to create in a laboratory and have also proven challenging to analyze because of the mixing of the various automotive paint layers. Because the smeared paint in all likelihood undergoes melting due to the heat generated by the impact, a separation phenomenon may occur due to differences in viscosities and/or affinities for the substrate by specific layers.

Charpy Impact Tester A controlled weight pendulum is swung from a set of heights (see Figure b in next slide) Subsequently, it strikes a standard notched specimen supported at both ends on an anvil, fracturing it (see Figure c-e in next slide) The amount of energy absorbed by the specimen is measured by recording the height of the pendulum at the end of the swing (see Figure c in next slide)

Charpy Impact Tester c a b Startin g positio n End of swing h h o f f e Specim en d Strik er Anv il Motorized pendulum impact testing system a) Simplified illustration of the Charpy impact tester, (b-e) impact load and impact energy (lost to the specimen) characteristic of a steel specimen (f) acquired in ms time intervals

Simulated Vehicle Collisions The impact velocity is controlled by the initial height of the pendulum; the pendulum momentum at the onset of the collision is controlled by its mass and initial height The collision is a dynamic process, during which sliding occurs between the two surfaces resulting in a smear. The frictional force, responsible for the smear, depends on the normal force, which in turn depends on inertia (momentum) and the viscoelastic response of the colliding bodies

Charpy Impact Tester Paint-transfer sample a Striker In b and c, the reaction force is mainly created by the bending of the automotive specimen (elastic response) which we call the coupon Paint smear Accessory I Before Collision b Striker Coupon Paint smear c Accessory I After Collision

Simulated Vehicle Collisions Here energy is dissipated to friction as well as deformation of the coupon. The initial contact angle between the coupon and the striker is adjusted by mounting the coupon on the accessory using wedge washers. During the collision, the contact angle continuously changes with sliding and bending of the coupon. The accessory design emulates the sheet metal deformation in a real automotive collision.

IR Microscopy A paint smear was obtained in which all layers were resolved. As revealed by an ATR-IR microscope, there was separation of the automotive paint layers in some regions. In contrast, the paint smear appeared intact everywhere using transmission IR microscopy. The unmixing was evident only with ATR-IR microscopy because of its superior spatial resolution.

IR Microscopy The transferred paint smear was separated from the inert metal substrate using a sharp knife. An IR image map was obtained from the smear using the imaging ATR accessory of the iN10MX IR microscope. Spectral line maps generated from this IR image map were decatenated to the pure spectrum of each layer using multivariate curve resolution (alternating least squares algorithm).

ALS Conditions The full IR spectrum of the paint samples, 4000 to 860cm-1, were used as input to ALS. Non-negativity and unimodality were both applied as constraints for the ALS algorithm. Initial estimates of the profiles for each constituent were provided by the Varimax Extended Rotation (see Barry K. Lavine, Jason P. Ritter, and Edward Voigtman, Multivariate Curve Resolution in Liquid Chromatography Resolving Two Way Multicomponent Data Using a Varimax Extended Rotation, Microchemical Journal 2002, 72(2), 163- 178)

Decatenated IR Spectrum of Clear Coat (red) Compared to IR Spectrum of Clear Coat from Original Sample (black)

Decatenated IR Spectrum of Surfacer (red) Compared to IR Spectrum of Surfacer from Original Sample (black)

Decatenated IR Spectrum of E-Coat (red) Compared to IR Spectrum of E-Coat of Original Sample (black)

Spectral Library Searching Library searching of the decatenated spectra was performed using an ATR simulated library of the clear coat (OT2), surfacer (OU2) and e- coat (OU1) layers. These ATR simulated spectral libraries were calculated from IR transmission spectra of GM paint samples (2000-2006 production years) in residence in the PDQ database. An ATR simulation algorithm was used to convert the transmission IR spectra from PDQ into ATR spectra.

OMNIC Search OMNIC was configured using correlation for search type and Happ- Genzel for the apodization function as this set of conditions generally yielded the best results when searching automotive top coat and undercoat layers The ATR spectra were ranked for best match using the hit quality index to assess similarity between the ATR spectrum reconstructed for each layer using MCR and each library entry for a particular layer.

OMNIC Search The top five hits identified by the hit quality index for each layer were compared to the model and line of the vehicle from which the paint sample was obtained. The reconstructed ATR spectrum was judged to be correctly matched if the correct line and model were found in the hit list (top five hits) for that layer

Library Search Results OT2 OU1 OU2 Hit HQI Hit HQI Hit HQI 4th match 97.93 2nd Match 96.58 2nd Match 95.77 All reconstructed ATR spectra were correctly identified by OMNIC and were typically second matches.

Conclusions Transfer of automotive paint resulting in a smear is caused by sheer stress created by friction. In the absence of heat generation, the paint is brittle and paint transfer will occur in the form of chips. The question as to the specific conditions of the collision that lead to a paint chip being transferred during a hit run versus a clear coat smear or a paint smear involving the mixing of multiple layers of paint can be answered using this approach

Acknowledgements Mark Sandercock, Royal Canadian Mounted Police Forensic Laboratory, 15707-118th Avenue, Edmonton, Alberta T5V 1B7 Koichi Nishikida, Materials Science Center, College of Engineering, University of Wisconsin, Madison, WI 53706 National Institute of Justice 2017-IJ-CX-0022.The opinions, findings, and conclusions or recommendations expressed in this publication / program / exhibition are those of the author(s) and do not necessarily reflect those of the Department of Justice.