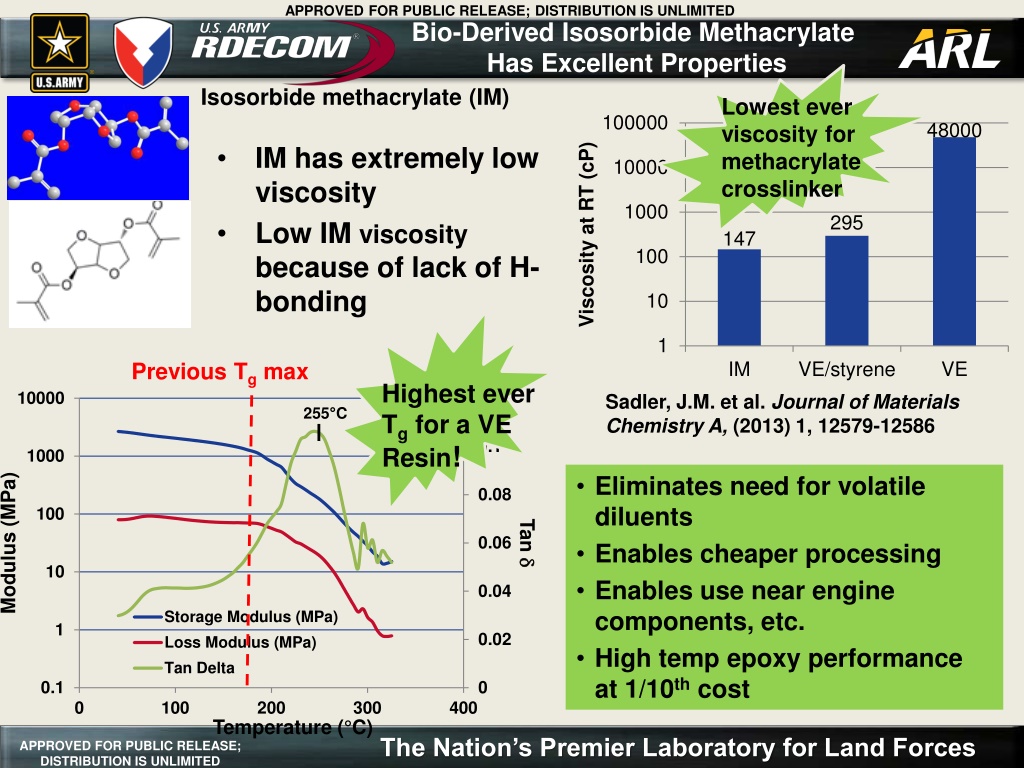

Advanced Methacrylate Crosslinker with Unique Properties

Discover the innovative bio-derived Isosorbide Methacrylate (IM) with exceptional properties such as ultra-low viscosity, high Tg, and cost-effective processing. This novel crosslinker eliminates the drawbacks of traditional methacrylates, offering superior performance for various applications. Explore the efficient synthesis methods and advantages of this cutting-edge material for high-temperature epoxy formulations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Bio-Derived Isosorbide Methacrylate Has Excellent Properties Isosorbide methacrylate (IM) Lowest ever viscosity for methacrylate crosslinker 100000 48000 IM has extremely low viscosity Low IM viscosity because of lack of H- bonding Viscosity at RT (cP) 10000 1000 295 147 100 10 1 IM VE/styrene VE Previous Tg max Highest ever Tg for a VE Resin! 10000 0.12 Sadler, J.M. et al. Journal of Materials Chemistry A, (2013) 1, 12579-12586 255 C 0.1 1000 Eliminates need for volatile diluents Enables cheaper processing Enables use near engine components, etc. High temp epoxy performance at 1/10th cost Modulus (MPa) 0.08 100 Tan 0.06 10 0.04 Storage Modulus (MPa) Loss Modulus (MPa) Tan Delta 1 0.02 0.1 0 0 100 200 300 400 Temperature ( C) The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Pros and Cons of IM and Methacrylates Pros: IM has very high Tg IM has very low viscosity Cons All methacrylates require separations to remove unwanted by products This technology described herein eliminates the Cons of methacrylates The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Typical Methacrylate Preparation 4-DMAP + + 40-60 C TEA, DCM + HCl + 0-25 C Separations step necessary to remove Solvent-aqueous liquid-liquid extraction generally required to extract HCl from methacrylate or to separate out methacrylic acid from methacrylate product. Separation process increases cost by factor of ~2. The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Novel IM Methacrylate Preparation 4-DMAP + + 40-60 C AMC-2 or imidizole 70-95 C An epoxy is added to the IM/methacrylic acid mix. The epoxy and methacrylic acid react to form a mono-methacrylate reactive diluent. Method eliminates need for separation of methacrylic acid (or HCl) Reactive diluents are typically added to crosslinkers to help produce a well cured thermoset. The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Use of other Alcohols + + 4-DMAP + 40-60 C + + AMC-2 or imidizole 70-95 C Mono alcohols will produce reactive diluents Diols will produce crosslinking agents Both will modify the resulting resin properties The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Novel IM Methacrylate Preparation O O O O O R OH + + and/or O O O O O O O R O Catalyst T = 25 C ~ 100 C O O O OH OH OH O O O O + O O + R R O O O O O O Mono epoxies produce reactive diluent Diepoxies react to produce dimethacrylate crosslinkers Use of mono- and di-epoxies allow tuning of the resin composition, crosslinker content, viscosity, and polymer properties. The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED IM + DGEBA and PGE Epoxy compound: - Will consume methacrylic acid - Will produce reactive diluents or crosslinkers that can copolymerize with IM - Any epoxy compound can be used + Phenyl glycidyl ether (PGE) + + DGEBA or Epon AMC-2 or imidizole Vinyl ester of PGE (VE-PGE) 70-95 C + + Vinyl ester of DGEBA (VE) The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Novel IM Preparation Properties Baseline VE Method results in resins where low viscosities are achievable. Viscosities are tunable depending on the alcohols and epoxies used. 100000 IM + epoxy methacrylates made using new method 10000 Viscosity (cP) Baseline IM 1000 100 300 IM + epoxy methacrylates made using new method Baseline IM 10 Glass Transition Temperature ( C) 250 Baseline VE 1 200 150 100 Method results in polymers where high Tg is achievable. Tg is tunable depending on the alcohols and epoxies used. 50 0 IM enables increased Tg with reduced viscosity! The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED Benefits and Applications Elimination of acid, tunable viscosity, and tunable polymer properties. Use of IM enables attainment of very high Tgs and low viscosities Reduces cost of the resins vs. that of pure IM or other methacrylate systems because method eliminates costly separation step. IM has low toxicity and is bio-derived Provides benefits for the following applications Composites low viscosities allows resin flow through fibers. Higher Tg allows for higher temperature use. Adhesives higher temperature applications. Additive manufacturing resins (stereolithography and ink jet printing) IM is very beneficial in this application because it does not have phenolic rings that reduce rate and extent of cure during photo curing. The Nation s Premier Laboratory for Land Forces APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED