Internal Audits and Management Review Meetings at European Spallation Source

This content discusses the internal audits and management review meetings conducted at the European Spallation Source. It covers topics such as quality division, ESSMS architecture, development of excellence, ESSMS procedures, and audit programs. The focus is on ensuring compliance, continual improvement, and excellence in operations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

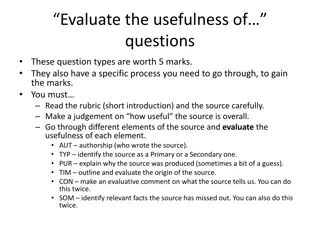

Internal Audits Management Review Meetings Quality Division Ivan Korunoski www.europeanspallationsource.se 24-08-01

ESSMS- Architecture European Spallation Source ERIC Mission, Vision, Core values Policies Strategies Objectives ESSMS Manual People 12 WoW Facility WoW Dev. Excellence & ESSMS Owner appointment letters Top level Org. description Functional Descriptions R2A2 WoW Handbook 12. WoW Handbook 1. WoW Handbook 3. WoW Handbook 2. WoW Area Handbook Baselined Facility documents Supportive doc s Templates 2

Agenda WoW Develop Excellence and ESSMS Main activities introduction Internal Audits Steering documents and evidence of execution Self Assessments Skanska and ESS (SEC) Management Review Meeting Steering document and evidence of execution 3

ESS WoW Develop Excellence and ESSMS WoW area consist of two main activities: Develop ESSMS ESSMS Architecture/structure WoW areas People leg Develop Excellence Internal Audits Management Review Meeting Management of Non Conformities Continual Improvements 4

Internal Audits Internal Audits ESSMS documents defining the method to be applied: ESS Procedure for Internal Audit ESS Procedure for Audit Program ESS Plan for Audits (2018/2019) Result of method application (evidence of execution): Audit Management Status / Reports 5

ESS Procedure for Internal Audits ESS-0008822 Preparing & Initiating Preparing Conducting Completing distributing the Audit the Audit the Audit the Audit Audit Report Based on ISO 19011 guideline for Auditing Management Systems Individual Audit in Focus, Instructions on how to perform an audit Auditing Principles for good Safety/Quality culture Definition of roles involved in Audit Internal Audits are on Management Review agenda 6

ESS procedure for Audit Program ESS-0015177 Establish Audit Establish the Audit Implement the Monitor the Audit Review/Improve Program Objectives Program Audit Program Program Audit Program ESS wide Audit Management in scope Director General assignment for HoQ* Division Instructions on how to build and implement ESS Audit Plan (ESS-0242768) Annual revision and follow up during MRM** Overall Audit Objectives as starting point dialogue around Management priorities 7 *HoQ- Head of Quality; **MRM- Management Review Meeting

ESS Plan for Internal Audits Audit scope and schedule for each Internal Audit During MRM 2017, Audits Plan has been agreed MRM 2018, EMT will review the Audit Plan fulfilment and suggest new areas for Audits ESS Audit Plan (2018/2019) ESS-0242768 Test Stand 2 inspection (February 2018) Logistic Function (April 2018) a) Handover process (from construction phase to trial operation/operation) b) Design release process including change handling (September 2018) 2018 Working permits and access control/Operating Limits and Conditions (Before start of or in the early beginning of trial operation) Incident Reporting and connection to emergency escalation/Competence, staffing and verified skills for safety significant positions (Before start of or in the early beginning of trial operation) 2019 8

Test Stand 2 inspection - Performed Planned: February 2018 Objective: Test Stand 2 readiness for operation (e.g. criteria SSM regulations and conditions according to permit SSM2017-2659) with focus on: Executed: February 2018 Radiological safety, Conventional safety (e.g. Electrical safety), Training, Access control, Defined roles & responsibilities, Emergency procedures, Reporting non-conformities and incidents ESS Procedure for IA applied, Inspection Plan (ESS-0228634) and Report created (ESS-0239960) Auditors: Ida Bergstr m, J rgen Mattsson, Michael Plagge, observer Mattias Skafar Summary: Number of Non Conformities reported: 9 Number of Observations reported : 6 Identified best practices reported : 2 Audit Status: Open Non Conformities are not related to Radiological Safety Lessons Learned: Selection of Auditors and their authority should be clarified Current status: All assigned , 2 are closed Current status: All assigned, ongoing 9

Logistic Internal Audit - Performed Planned: April 2018 Objective: Working methods that have been set up compared to the original statement of work and delivery of the services by the Logistic Service Provider, with focus on : Executed: April/May 2018 Assignment and execution of work Financial Control ESS Procedure for Internal Audits applied, Internal Audit Report created (ESS-0280532) Auditors: Mattias Skafar, Natascha Parnefjord, Ivan Korunoski Summary: Number of Non Conformities reported: 3 Number of Observations reported : 1 Identified best practices reported : 1 Audit Status: Audit will be closed after verification of corrective actions (Nov 2018) Lessons Learned: Difference between Internal Audit and Internal Control Current status: All assigned, ongoing Current status: assigned, ongoing 10

Handover process Design release process including change handling Planned: September 2018 Objective: To analyse/assess and if possible approve the approach of Handing over buildings from Skanska Consortium to ESS, with focus on. Executed: September/October 2018 Delivered documentation alignment with ESS MS requirements Early Involvement of ESS central Services early in the process General improvement of handover principles, transfer of responsibilities and ownership Several formal meetings documented, report to Steering group, ETB and final Report created (ESS-0359154) Participants: Quality Division to chair the group reporting to Steering group ( Technical Director, Head of CF, Director of PS&S, Associated Director ESH&Q) Summary: Current approach was not well know Well documented and implemented as part of contractual agreement WoW Develop & Maintain owner of the future handovers Next step: Handover Working Group has been terminated Lessons Learned: Stakeholders communication 11

ESS overview of Non conformities and improvements in JIRA Total no of NCR registered in system: 24 (19 open and assigned and 5 closed) NCR from TS2 Audit: 9 (all assigned, 2 are closed) NCR from Logistic Audit: 3 (all assigned, ongoing) NCR from Project: 12 (7 open, all assigned, 5 are closed) Total no of improvements registered in system: 7 (7 open and 5 is assigned) Improvements from TS2 Audit: 6 (all assigned, ongoing) Improvements from Logistics Audit: 1 (assigned, ongoing) Improvements from Project: None. 12

ESS Self Assessments ESS EMT* performed Self Assessment MRM agenda 2017, Validation for Commitment to Excellence 3 Improvement Projects prioritized by EMT Learning Management System Decision Making Internal Communication Culture Assessment ESS Supply Procurement and Logistic Self assessment 3 Improvement Projects Contract Management Survey of Stakeholders feedback Knowledge sharing (0 cost) 2.Develop strategy/approach and plan for implementation 4.Implement the solution and measure/ verify effectiveness 1.Identify needs and stakeholder expectations 3. Develop documented solution Self Assessment WoW 2018 WoW Managers participated, one day Main Conclusions: Involvement of Owners Strategy development Measurements for WoW Input for ESS 2018 MRM Zero measurement WoW maturity status Excellence *EMT- Executive Management Team EFQM- European Foundation for Quality Management 13

Skanska & ESS Audit Management Skanska has, in order to facilitate an open and transparent cooperation with the client, created a company for constructing the infrastructure of the ESS research facility. The company is named Skanska ESS Construction HB (SEC) Spot-check, total 100 Spot-checks are carried out by the SEC quality function together with the SEC production. The spot-checks are typically carried out at the beginning of a work sequence and on quality critical works 90 80 70 48484949495151525253555657586061616163 60 Chapter 13. Quality handles procedures for: Non-conformities Spot-checks Audits Presently 63 Spot-checks (14 Internal Audits) have been carried out. Spot-checks 50 323234363942 40 30 2728 2023 20 0 0 0 0 02 2478910121414 May-15 10 0 Jul-15 Jul-16 Jul-17 Jul-18 Nov-15 May-16 Nov-16 May-17 Nov-17 May-18 Nov-18 Jan-16 Mar-16 Jan-17 Mar-17 Jan-18 Mar-18 Sep-15 Sep-16 Sep-17 Sep-18 14

ESS procedure for Management Review Meeting (MRM) ESS-0004672 Based on ISO 9001, EMT review and decision forum Standard Agenda First ESS MRM performed in 2016, 2018 MRM scheduled for 27thof November Quality Division assists DG in preparation, realization and communication (MoM, action plans released) Half Year review progress on DG request 15

Conclusion WoW Develop Excellence and ESSMS Introduction and relation to top WoW map WoW area Main activities Internal Audits and evidence of execution Status of Non conformities and improvements Self Assessments SEC Audits Management Review Meeting and evidence of execution Plan for 2018 16