Utilization of Algae for Biofuels Production: A Comprehensive Overview

Algae, both microalgae and macroalgae, hold immense potential as sources of biofuels due to their high productivity and adaptability. Microalgae, in particular, are highlighted for their rapid growth rates and efficient photosynthesis, making them ideal for mass production with minimal land and water usage. Despite their advantages, challenges such as low biomass concentration and energy-intensive harvesting processes exist. The history of algae biofuels dates back to the 1950s, with ongoing research and advancements in cultivation techniques. The promising potential of microalgae biodiesel, with oil content exceeding 80% of dry biomass, underscores their role in sustainable fuel production.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Utilization of Algae for Biofuels Production Supervisor: Prof. H. S. Ghaziaskar By: M. Rezayat Department of Chemistry Jun 1, 2010

Outline Introduction Algae Microalgae As a potential replacement fuel Large scale production Harvesting and drying Fuel production Oil extraction Economic biodiesel production 2

Biofuels Forestry Agriculture Aquatic Bio-diesel Bio-oil Bio-gas Biomasses 1.8-2.2% 6-8% Biomass Oxygen 3

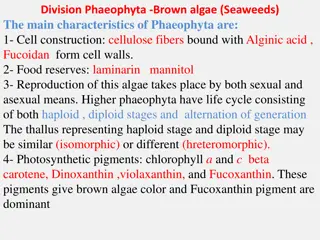

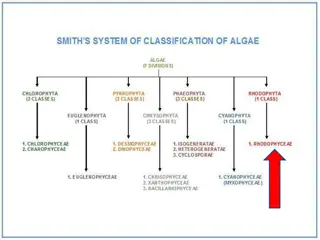

Algae Microalgae: Microscopic photosynthetic organisms In both marine and freshwater environments. Macroalgae (seaweed): Multicellular plants In both salt or fresh water, They do not have roots, stems and leaves 60 m in length Applications: Used as food as powder or tablet( Spirulina, Chlorella, ), animal food As a chemical sources Wastewater treatment( heavy metals) Solar energy conversion and biofuel production. As agent for enhanced CO2 fixation. 4

They should be: Highly productive Easily harvestable by mechanical techniques Withstand water motion in open ocean( Macroalgae) Produced at a desirable cost Adaptable to grow in different conditions Fresh or marine-waters Wide range pH 5

Why Microalgae? High grow rates Simple structure High Photosynthetic efficiency Advantages: Massive production while using limited land Consuming less water high- efficiency CO2 mitigation Nitrous oxide release could be minimizing More cost effective than conventional farming 6

Disadvantages: Low biomass concentration Small size makes their harvest relatively costly. Drying would be energy-consuming process. History : 1950s, the first report on algae biofuels at MIT. 1970, initial examination on algae. Algae Culture from Laboratory to Plant (Burlew, 1953) 1980, subsequent studies 7

Potential of Microalgae biodiesel Double their biomass within 24 h. Their oil content exceed 80% by weight of dry biomass. 8

Photosynthetic needs: Light Carbon dioxide Water Inorganic salts ( N, P, Fe) 20-30 C CO0.48H1.83N0.11P0.01 50% of dry weight is Carbon Producing 100 tons algae biomass 183 tons CO2 9

Large scale production Raceway ponds o Cost less to build & operation Photobioreactors o Provide much greater oil o Recovery cost is less o Biomass concentration is 30 times raceway ponds production 10

Raceway ponds Used since the 1950s 440,000 m2(2006) Closed loop channel 0.3 m deep Mixing and circulation by Paddlewheel Cooling by evaporation Temperature fluctuation Contamination with unwanted algae and microorganisms Poorly mixed Biomass concentration is low Dark zone 11

Photobioreactors Single-species culture Array of straight tube(plastic or glass) 0.1 m in diameter Parallel to each other and flat above the ground (Oriented North-South ) The ground painted white or covered with white plastic Using a pump for maintaining a turbulent flow (a mechanical or a gentler airlift pump) Must be cleaned & disinfected 12

Oxygen removing 10 g m-3min-1 Inhibit photosynthesis Photooxidative damage Need to a degassing zone Tube length 80 m Biomass concentration Light intensity Flow rate Oxygen concentration (entrance of tube) 13

Enhance CO2 Solubility (US2009/0151241 A1) Providing a perfluorodecalin (C10F18) solution. Mixing it with biological growth medium & surfactant. Emulsifying them by circulation in a high-pressure emulsifier. Production of algae pigments (US2009/0035835 A1) entering mature algae to a stress bioreactor ( stress tank). Irradiating with electromagnetic waves of mm rang and low intensity. Using optical fibers to enhance lighting 16

Harvesting and Drying long time Decomposition Microalgae harvesting: Chemical and biological flocculation Filtration Centrifugation Ultrasonic aggregation More efficient More costly long time, Large surface Loss of bioreactive products Microalgae drying: Sun drying Low-pressure self drying Drum drying Spry drying Freeze drying More efficient More costly 17

Fuel production Direct combustion (boiler & steam turbines), high moisture content Anaerobic digestion (Macroalgae), CH4 & CO2 Gasification , Syngas Low temperature catalytic of biomass Pyrolysis (750 K , 0.1-0.5 Mpa, in absence of air) Oil-like liquid ( bio-oil) Dried mass Carbon-rich solid (charcoal) Hydrocarbon rich gas 18

Pyrolysis: Fast-flash (low Temp. & high heating rate) Slow (low Temp. & heating rate) High Temp. & low heating rate at long residence time Liquid oil Char Fuel gas Liquefaction Low Temp. , high Pressure Using catalyst Recover liquid fuel More expensive than pyrolysis 19

Oil Extraction from Algae Using a mechanical press ( 70% , cheap) Solvent extraction ( n-hexane) Enzymatic extraction Osmotic shock Ultrasonic assisted extraction 20

Supercritical fluids Supercritical carbon dioxide extraction (SFE) 313-323 K, 25-30 MPa With or without co-solvent (1 mL methanol) Batch or continuous mode Pretreatment (grounding of dried at 308 K) Sub- or Supercritical water Hydrothermal conversion of algae to biofuel Lipid & free fatty acid 5-400 atm, 373-723 K 21

Biodiesel production Trans-esterification process Acid , alkalis and lipase enzyme Non-or mono-unsaturated fatty acids of 16 or 18 carbon length Rich in polyunsaturated fatty acids with four or more double bonds 22

Economic biodiesel production Microalgae bio-refinery can produce biodiesel, animal feed, biogas and electrical power. Cleaned Gases Co-Firing Green Power Power Plant / Energy Source Biodiesel Trans-esterification Flue Gases Ethanol Fermentation NOx + CO2 from combustion flue gas emissions Protein Meal 23

Integrated pollution control and biodiesel production Microalgae farming and CO2 mitigation Planet, 0.03-0.06% Chlorella sp. 10-50% Microalgae farming using wastewater Removing of N, P and heavy metal Microalgae farming using marine microalgae Red marine algae, green marine algae and marine phytoplankter CO2 and Nox mitigation 24

Enhance algae biology Molecular level engineering can be used to potentially: Increase photosynthetic efficiency Enhance biomass growth rate Increase oil contant Improve temperature tolerance Eliminate the light saturation phenomena Reduce photo-inhibition Reduce sensitivity to photo-oxidation 25

References [1] D. Bowle, Micor- and Marco-Algae: Utility for industrial application, Economic Potential of Sustainable Resources Bioproducts, 2007. [2] Food and Agriculture Organization of the United Nations (FAO), Algae-based biofuels, www.fao.org/bioenergy/aquaticbiofuels, 2009. [3] G C. Dismukes, D. Carrieri, N. Bennette, G. M. Ananyev, M. C. Posewitz, Curr. Opin Biotechnol, 2008, 19:235 240. [4] Y. Chisti, Biotechnology Advances, 2007, 25, 294 306. [5] J.ohn Sheehan, T. Dunahay, J. Benemann, P. Roessler, A Look Back at the U.S. Department of Energy s Aquatic Species Program Biodiesel from Algae, National Renewable Energy Laboratory,1998. [6] G. Taylor, Energy Policy, 2008, 36, 4406 4409. [7] Y. Li, M. Horsman, N. Wu, C. Q. Lan, N. Dubois-Calero, Biofuels from Microalgae, 10.1021/bp070371k CCC, 2008. [8] F. Lehr, C. Posten, Curr. Opin. Biotechnol. 2009, 20,280 285, [9] L. L Beer, E. S Boyd, J. W Peters, M. C. Posewitz, Curr. Opin. Biotechnol. 2009, 20, 264 271. [10] P. F.F. Amaral, M. G. Freire, M. H. M. Rocha-Lea o, I. M. Marrucho, J. A.P. Coutinho, M. A. Z. Coelho, Biotechnol. Bioeng., 2008, 99 ,588-598. [11] M. Aresta, A. Dibenedetto, G. Barberio, Fuel Processing Technology, 2005, 86, 1679 1693. 26

[12] N. Mitropoulos, WO 2008/151373 A1. [13] C. Keeler, J. D. Stephenson, S. W. Schenk, B. Cloud, M. Bellefeuilie, WO 2010/017002A1. [14] G. Erb, D. R. Peterson, US 2010/0034050 A1. [15] E. H. Katchanov, US 2010/00118214 A1. [16] J. R. Munford, GB.2447905 A. [17] V. Slavin, US 2009/0035835 A1. [18] L. V. Dressler, US 2009/10151241 A1. [19] R. Downy, WO 2010/027455A1. [20] T. Merimon, J. McCall, US 2010/0068791. [21] B. Chian-pin Wu, C. A. Deluca, E. K. Payne, US 2010/0050502. 27

Bio-hydrogen Steam-reformation of bio-oils Photolysis of water catalyzed by special microalgae species Indirect photolysis, Anaerobic Hydrogen starch Cost of the huge bioreactors Cost of hydrogen storage facilities (night or cloudy day) 31