Key Aspects of Process Control in Combing for Optimal Yarn Quality

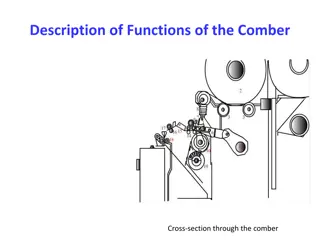

Combing in combers is crucial for controlling waste levels, combing efficiency, and sliver irregularity, especially with Indian cottons. Adjusting detaching distance and understanding sliver variation are key factors. Combing performance directly impacts yarn quality and waste extraction. Utilizing modified combs and maintaining proper settings are essential for achieving high-quality yarn with minimal waste.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

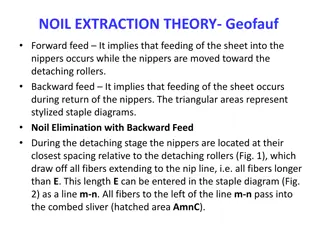

Process Control in Combing In combers, the important aspects to be controlled are waste level, combing efficiency and sliver irregularity. Best results of combing of Indian cottons are generally achieved by suitable adjustments of detaching distance. However, the cottons have a high fiber length uniformity but the lap contains too many impurities and neps, a deep penetration of top comb is desirable, without fiber rupture., combing efficiency and sliver irregularity. Mill process all classes of cottons in the same comber without regard to the suitability of the needling Incase of heavier laps, it increases the comber waste by 2 to 3% as compared with lighter laps.

Sliver Variation Sliver variation in comber is due to short term irregularity and Control of this short-term irregularity of comber sliver is very important. A high sliver U% can lead to increase in within- bobbin lea count variation. The long-term variation of the comber sliver should be maintained within a C.V of 3% for one meter wrappings.

Combing Performance The performance of combers has also considerable bearing on yarn quality as well as the amount of waste extracted. The poor combing performance arises due to improper settings and timings, poor upkeep and inadequate maintenance, unsatisfactory lap preparation and unsuitable process parameters. If for every 1% comber extraction, 50% span length improves by 1.7% or more relative to card sliver, then the combing performance can be considered to be good. Generally, for comber waste extractions upto 10%, all cottons respond well to combing. For levels beyond 10%, the law of diminishing returns operate . Higher levels of waste should be extracted only in such cottons which indicate satisfactory combing performance or where the end use requires yarns of very high quality

The head-to-head and comber-to-comber variations in waste should not exceed 1.5% and 0.5% respectively from the average value. As per the studies, while using high speed combers, the modified unicomb half lap yields 10 15% higher combing efficiency, 30 to 40% reduction in comber sliver neps and 0.5 U% improvement in sliver evenness as compared to that obtained using conventional half lap at a comber speed of 200 nips/minute. Yarns produced using modified unicombs are stronger (5-12%) and more even. It is also observed that use of high speed combers with modified unicomb and modified top comb results in a significant improvement in infrequent faults (to the tune of 30%). In the modified comb, density of the needle is higher compared to normal top combs. If the normal top comb has 66 needles/inch, then modified comb will have 76 needles/inch.

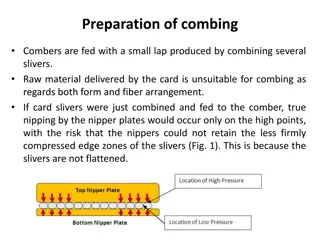

Sources of count variation in combers The short-term irregularity U% of the comber sliver has a significant influence on within-bobbin count variation, whilst long-term variation of about 0.15 to 0.3m. The causes for high sliver U% include, Eccentric top and bottom rollers Misaligned and bent nippers Improper needle spacing Broken or bent needles Variation in detaching roller diameters and improper timing of top combs Damaged or improperly meshed gears Phasing of piecing waves Chocked aspirator systems Defective weighing and improper trumpet size for the hank

Higher Comb Sliver Variation Differences in waste extraction between heads. Variation in the settings between back detaching roller and nipper Improper cam setting depending upon the staple length of the material. Unicomb chocked with seed coats or immature cotton Wider setting between unicomb and comb cleaning brush. Eccentric top and bottom rollers. Mis-aligned and bent nippers. Improper needle spacing Broken or bent needles Variation in detaching roller diameters and improper timing of top combs Damaged or improperly meshed gears Phasing of piecing waves, Chocked aspirator systems Defective weighing and improper trumpet size for the hank

Thick and Thin Bars in Comber Web Incorrect timing of the detaching roller cam. Top comb set too deeply Top comb touching the back detaching roller. Improper pressure on nippers. Lap Running Slack Improper feed-ratchet movement. Lap loose on the shaft. Insufficient tension draft between lap roller and feed roller.

Differences in Noil between Heads Variation in top comb penetration between the heads of the same comber. Variation in setting between unicomb and bottom nipper. Improper setting of the cam which decides the length of overlapping after combing. Uneven and insufficient nipper grip Variation in diameter and pressure of top detaching rollers. Obstruction in the movement of aspirators.

Poor Combing Efficiency Presence of fiber hooks or disorderly arranged fibers due to non-standard preparatory process. Timing of the combing cycles not adjusted properly. Top comb chocked with short fibers/ immature fibers. Inadequate penetration of top comb Half-lap cleaning brush loose on shaft or set too far from the cylinder. Excessive variation in short fiber content in the mixing. Wider setting between unicomb and nipper. Inconsistent mixing of soft waste.

Poor Nep Removal Efficiency in Combers Factors that decides the amount of nep removal depends on top comb depth and nipper to half-lap setting. Cylinder with high diameter (6 instead of the conventional 5 ). Causes Higher combing times using half laps covering 120o of the cylinder. Wider setting between half lap and bottom nipper. Wider setting between cleaning brush and stripping rail. Low penetration of brush with half lap. Insufficient penetration of top comb. Uneven nipper grip. Damaged needles in unicomb. Damaged/absence of top roller clearer cloth. Incorrect atmospheric conditions.

Degrees of Combing Scratch Combing, where up to 5% noil is removed. This gives no great improvement in average yarn properties but has the benefit or reducing end breakage rates in spinning and winding. Half-combing, which involves around 9% waste, resulting in reduced yarn irregularity and improved spinning performance Ordinary combing, involving between 10 to 18% noil, which is necessary for spinning yarns in the finer end of the count range. Full combing, resulting in greater than 18% noil. This often means double combing to obtain the highest quality yarns 18% removed in the first combing and 7% in the second.