Understanding Particle Motion in Fluids: Dynamics and Phenomena

Exploring the intricate dynamics of particle motion within fluids, this content delves into mechanical micro-processes, particle velocity, terminal velocity, flow regimes, and the calculation of drag coefficients. It covers the Stokes region, laminar flow conditions, and considerations for transient regimes. The discussion includes equations and principles elucidated by Solomon Bogale from the Chemical Engineering Department.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Mechanical Micro-process in a fluid

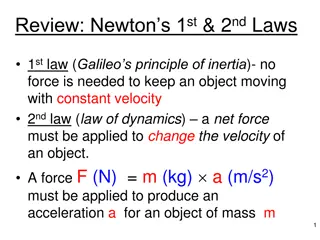

Motion of particles in a fluid FB = = = 3 W mg V g g P P P 6 Fd = = 3 F V g g B f f f 6 v 2 W dx = 2 F C d f d 8 dt 2 d x = = 3 W F F ma B d P 2 6 dt Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid 2 2 dx d x = 3 3 2 3 g g C P f f d P 2 6 6 8 6 dt dt ( )( ) 2 3 C 2 d x dx P f f d = g ( )( 4 ) 2 dt dt P P ( )2 x = 1 * 2 * * x h g h C d When the net force is zero the particle moves with constant velocity known as terminal velocity. h g h * 2 * 1 0 = ( ) x 2 * C d 1 h g = = * x v 2 h C d = * x v t Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid * 2 3 * * g * v C * 4 * * * g f d = = v ( ) 3 * 4 * C f d The value of Cd is determined by the flow regime; the majority of sedimentation phenomena involve laminar flow conditions. Solomon Bogale Chemical Eng'g Department

Cd = f (Re) Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid stokes region: Re 2 and Cd Cfd = 24/Re Laminar flow: For accelerating particle ( 2 ) 18 2 d x 2 dx f = g ( ) ( ) dt dt P P For steady rate of fall: ( 2 ) 18 dx f = 0 g ( ) ( ) dt P P 18 * * v 2 * * g f = = v 18 * * g f

Motion of particles in a fluid The stoke s region has an upper limit: Re = 2 and Cd = 24/Re = 12 * 2 * f max= v From Re: max f 4 * * * g = max v From equation ( ): max 3 * 12 * f ( ) 2 * * 36 g * g f f = = 2 * v ( ) 3 3 max, max, lam lam 2 * * 36 * f f Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid Transient regime: 2 < Re < 500 and Cd = 18.5/Re0.6 Substituting Cd in equation ( ) gives: 1 4 6 . 1 4 * * * g = v ( ) ( ) 4 . 0 6 . 0 55 5 . * * f f . 1 143 . 0 714 . 0 714 . 0 1528 * * * g = v ( ) ( ) . 0 286 . 0 429 * f f . 0 25 . 0 375 . 0 875 . 5 175 * * * v f f = . 0 625 . 0 625 * g Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid The upper boundary of the transient region: Re = 500 and Cd = 18.5/5000.6 * max 500 * f max= v From Re: f 6 . 0 4 * * * * 500 g = max v From equation ( ): max 3 * * 18 5 . f ( ) * 2 * * g f f = = 11 45 . * 43 68 . * v ( ) 3 3 max, max, tran tran 2 * g f f Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid Turbulent regime: 500 < Re < 2e5 and Cd = 0.44 * 2 . 0 33 * * v 33 * * g f = = v . 0 * g f Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid Applications 1. Separation of particles of a given material according to size Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid ( ) vp= f is the same p

Motion of particles in a fluid Applications 2. Separation of particles of the same size, but of different composition (materials A and B with A> B) In a liquid of intermediary density ( B < f < A) In a liquid whose density approaches that of the lightest particles ( f B < A)

= A B ( ) v f B A = A f f v v v B A f as v v f B B f v A v B

Motion of particles in a fluid The sedimentation velocity of the heavier particles are bigger than that of lighter ones according to the ratio: ( ( ( ) ( ) ( ) ( ) ) ) 1 = v v Laminar flow A B A f B f . 0 714 = v v Transient A B A f B f 5 . 0 = v v Turbulent A B A f B f Solomon Bogale Chemical Eng'g Department

Motion of particles in a fluid Applications 3. Separation of particles differing both in composition and size In a liquid with ( f < B < A) ( A A B = m ) ( ) f B f m = 0.5 in laminar m = 0.625 in transient m = 1.0 in turbulent Solomon Bogale Chemical Eng'g Department

= , for v v A B ( ) = B f f A f B A v v ( ) A f if f f B v v min B f

Example 1: Estimate the terminal velocity for 0.08mm particles of limestone ( s=2450 kg/m3) falling in water at 30oC. Given : water = 995.7kg/m3, water = 0.801x10-3 kg/m-s ( ) ( . 0 ) 2 2 36 * 36 * 801 3 e f = = . 1 = 18 4 e m 3 3 ( ) max, lam * * . 9 81 * 995 7 . * 2450 995 7 . g f = . 1 = 8 5 18 4 e m e m max, lam ( ) ( ) 2 2 * * 8 5 . 9 * 81 * 2450 995 7 . g * e = = = . 6 33 3 / v e m s ( . 0 ) 18 18 * 801 3 e f

Example 2: Find the size of a spherical particle of glass that has a terminal settling velocity of 7.4mm/s in a fluid of density 982kg/m3 and viscosity 0.0013kg/ms. Density of glass is 2800kg/m3. ( ) * * g 36 . 9 81 0013 . 0 * * 2800 982 f = = 2 * 2 * v ( ) 3 3 ( ) max, lam 2 2 * 36 * 982 f = 0175 . 0 / v m s max, = lam . 0 0074 / v m s v max, lam 18 * * v * 18 0074 . 0 * 0013 . 0 * f = = = 1 4 e m ( ) . 9 81 * 2800 982 g

Example 3: Calculate the minimum density of the fluid, viscosity = 0.005 Pa-s, needed to separate lead ore particles ( Pb = 7500 kg/m3) completely from a matrix of quartz particles ( qu = 2650 kg/m3); both minerals are characterized by a particle size distribution ranging from 0.015mm to 0.065mm. ( ) 1 2 7500 65 f = = 3 2377 kg m In laminar flow: f 15 2650 f ( ) 1 7500 65 In turbulent flow: f = = 3 1195 kg m f 15 2650 f

Re Calculate and for the largest and the smallest particles in the two different fluids of density 1195 and 2377 kg/m3 respectively. Lead Quartz Re Re Diameter 0.015e-3 1.26e-4 8.96e-4 6.70e-6 4.77e-5 0.065e-3 2.36e-3 7.29e-2 1.26e-4 3.89e-3 In all cases under consideration laminar flow prevails. Thus the density of the fluid is: f= 3 2377 kg m

Example 3.1 (Coulson) What is the terminal velocity of a spherical steel particle, 0.40 mm in diameter, settling in an oil of density 820 kg/m3 and viscosity 10 mN s/m2? The density of steel is 7870 kg/m3. Example 3.2 (Coulson) A finely ground mixture of galena and limestone in the proportion of 1 to 4 by mass is subjected to elutriation by an upward-flowing stream of water flowing at a velocity of 5 mm/s. Assuming that the size distribution for each material is the same, and is as shown in the following table, estimate the percentage of galena in the material carried away and in the material left behind. The viscosity of water is 1 mN s/m2 and Stokes equation may be used. The densities of galena and limestone are 7500 and 2700 kg/m3, respectively. Diameter ( m) 20 30 40 50 60 70 80 100 Undersize (per cent by mass) 15 28 48 54 64 72 78 88

Exercise : Polyethylene spheres, density = 910 kg/m3 and diameter 3.4mm, settle in air of density = 1.218kg/m3 and viscosity = 1.73e-5 pa-s. calculate: a. Their steady rate of fall; b. The time needed to settle over a distance of 2m at steady rate of fall Solomon Bogale Chemical Eng'g Department